Quantitative determination method of aminopyridine carcinogenic substances in meat products

A quantitative detection method, aminopyridine technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low recovery rate of target compound addition, unfavorable large-scale sample determination, cumbersome and complicated operation, etc., to save pretreatment The effect of time, accuracy improvement, and high application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

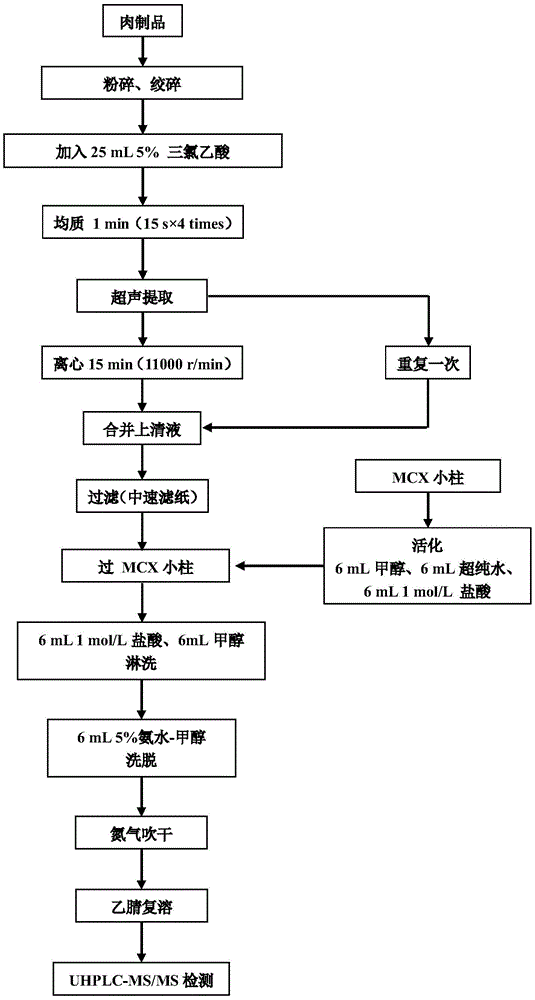

[0034] 1. Barbecue sample preparation: Purchase fresh pork and bake it at 225°C for 30 minutes, turn it over halfway through the specified time to obtain a barbecue sample, and grind it with a tissue grinder to obtain a barbecue sample powder.

[0035] 2. Add trichloroacetic acid for homogenization treatment: Accurately weigh 4.00g of barbecue sample powder and add it to the homogenization tube, and add 25g of 5% trichloroacetic acid aqueous solution to it, homogenize for 15s, repeat 4 times, among which, the homogenization adopts German IKAT- Type 25 high-speed dispersing machine, the speed of dispersing is 15000±250 rpm.

[0036] 3. Ultrasonic extraction: transfer the mixed solution obtained in step 2 into a conical flask, and then ultrasonically extract for 15±5min, the ultrasonic working frequency is 40±10kHz, and the temperature is room temperature.

[0037] 4. Take the supernatant by centrifugation: the centrifugation speed is 11000r / min, and the centrifugation time is 1...

Embodiment 2

[0055] 1. Sample preparation of smoked fish and roast beef: Grind commercially available smoked fish and roast beef with a tissue grinder. Accurately weigh 4.00g of barbecue powder and add it to the homogenizing tube to obtain homogenized barbecue powder

[0056] 2. Adding trichloroacetic acid: Add 25g of 5% trichloroacetic acid aqueous solution to the barbecue powder in step 1, homogenize for 1 minute with a high-speed disperser, and then transfer to a conical flask.

[0057] 3. Ultrasonic extraction: Ultrasonic extraction for 15±5min at an ultrasonic working frequency of 40±10kHz. After extraction, the mixture was transferred to a 50mL centrifuge tube, centrifuged for 15±5min, and the supernatant was collected, and the residue was ultrasonically extracted again, and the centrifuged supernatant was combined to obtain the supernatant.

[0058] 4. Adjust the pH of the extract: add 4mol / L NaOH solution to the combined supernatant to adjust the pH to 3.0±0.5, and use precision p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com