Biomass carbon/ferrocobalt dual-metal-oxide double-functional oxide catalyst as well as preparation method and application thereof

A bimetallic oxide, biomass carbon technology, applied in structural parts, electrical components, battery electrodes, etc., to achieve good OER and ORR catalytic activity, good methanol tolerance, and improved electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

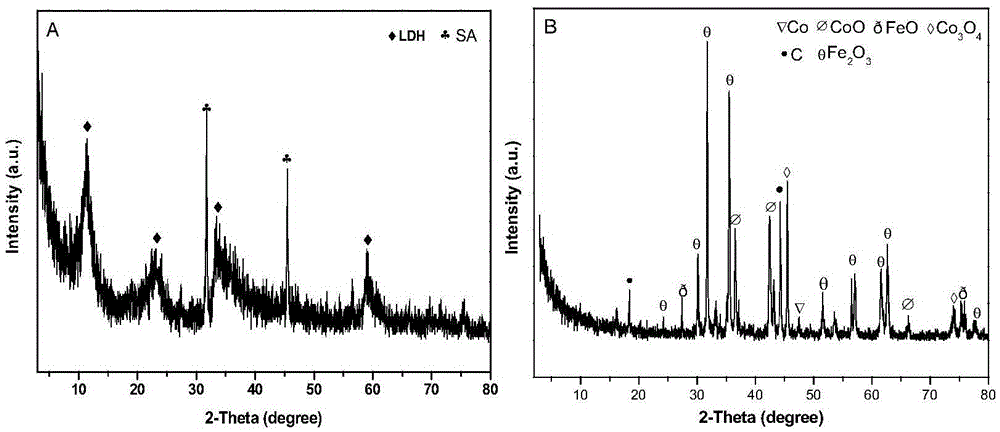

[0031] (a) Preparation of SA / LDH complex

[0032] Disperse a certain amount of SA in distilled water to make the concentration 2.5mg / ml, add cobalt chloride hexahydrate and ferric chloride hexahydrate into 150mL deionized water at a molar ratio of 3:1, so that the total concentration of metal ions is 0.016mol / L, stir and dissolve completely, then slowly drop into the SA solution, stir for 4h and then centrifuge at 3800rpm for 10min, collect the precipitate and redisperse it in 150mL deionized water, then add 1.5mol / L NaOH dropwise at a constant speed to adjust the pH of the reaction solution to 8 Left and right, transfer the above mixed solution into a reaction kettle, and conduct a hydrothermal reaction at 130°C for 24 hours. After the reaction solution is centrifuged, it is washed three times with deionized water and ethanol in sequence, and the SA / LDH complex is obtained after drying;

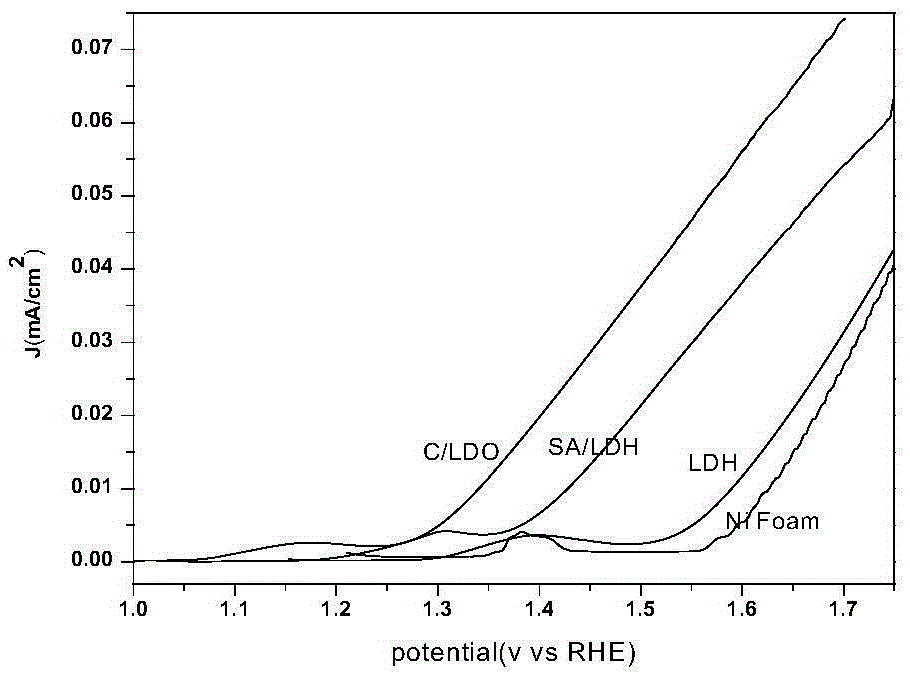

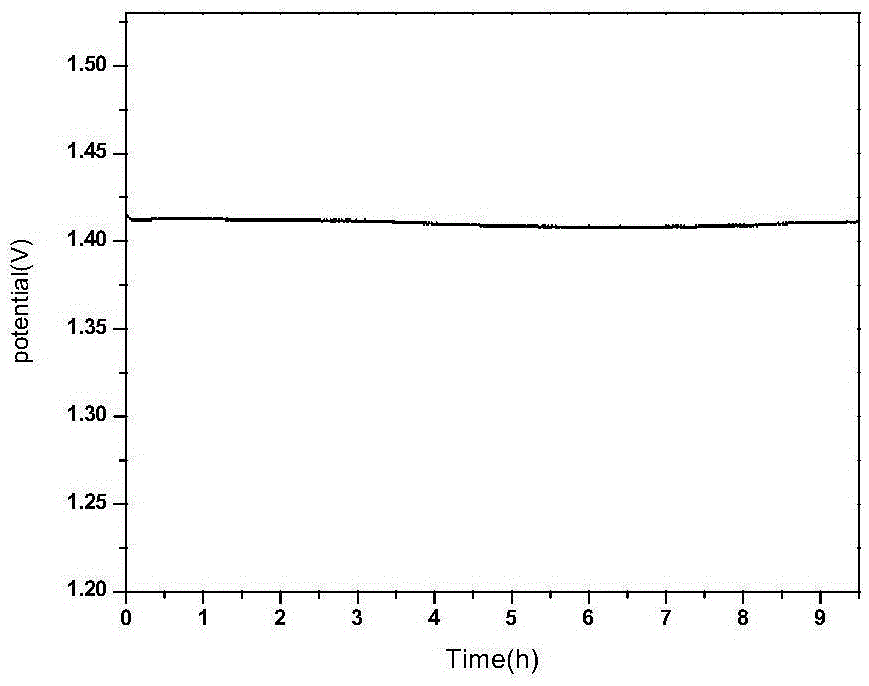

[0033] (b) Preparation of C / LDO bifunctional oxygen catalyst

[0034]Grind the SA / LDH ...

Embodiment 2

[0036] (a) Preparation of SA / LDH complex

[0037] Disperse a certain amount of SA in distilled water to make the concentration 5mg / ml, add cobalt chloride hexahydrate and ferric chloride hexahydrate in 150mL deionized water at a molar ratio of 3:1, so that the total concentration of metal ions is 0.016mol / ml L, stirred and dissolved completely, slowly added dropwise to the SA solution, stirred for 4 hours, centrifuged at 3800rpm for 10 minutes, collected the precipitate and redispersed it in 150mL deionized water, then added 1.5mol / L NaOH dropwise at a constant speed, and adjusted the pH of the reaction solution to about 8 , transfer the above mixed solution into a reaction kettle, conduct a hydrothermal reaction at 130°C for 24 hours, wash the reaction solution three times with deionized water and ethanol successively after centrifugation, and dry it to obtain the SA / LDH complex;

[0038] (b) Preparation of C / LDO catalyst

[0039] Prepare according to the method and conditio...

Embodiment 3

[0042] (a) Preparation of SA / LDH complex

[0043] Disperse a certain amount of SA in distilled water to make the concentration 10mg / ml, add cobalt chloride hexahydrate and ferric chloride hexahydrate into 150mL deionized water at a molar ratio of 3:1, so that the total concentration of metal ions is 0.016mol / ml L, stirred and dissolved completely, slowly added dropwise to the SA solution, stirred for 4 hours, centrifuged at 3800rpm for 10 minutes, collected the precipitate and redispersed it in 150mL deionized water, then added 1.5mol / L NaOH dropwise at a constant speed, and adjusted the pH of the reaction solution to about 8 , transfer the above mixed solution into a reaction kettle, conduct a hydrothermal reaction at 130°C for 24 hours, wash the reaction solution three times with deionized water and ethanol successively after centrifugation, and dry it to obtain the SA / LDH complex;

[0044] (b) Preparation of C / LDO catalyst

[0045] Prepare according to the method and condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com