Method for increasing content and oxidation resistance of nutritional ingredients in mango juice

A technology of anti-oxidation ability and nutritional components, which is applied in the direction of food components as antimicrobial preservation, function of food components, food components, etc. It can solve the problems of browning and precipitation of NFC mango juice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

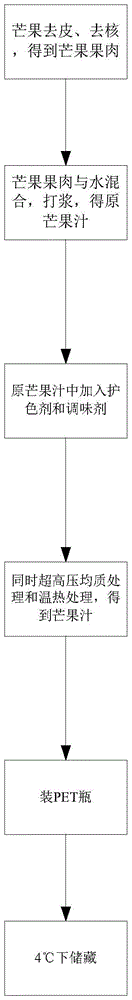

Method used

Image

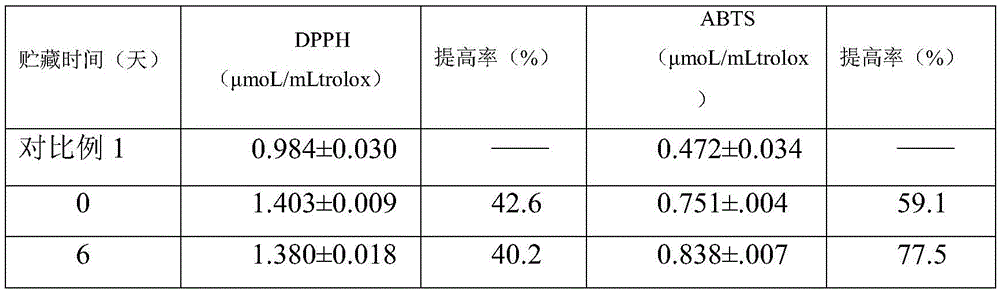

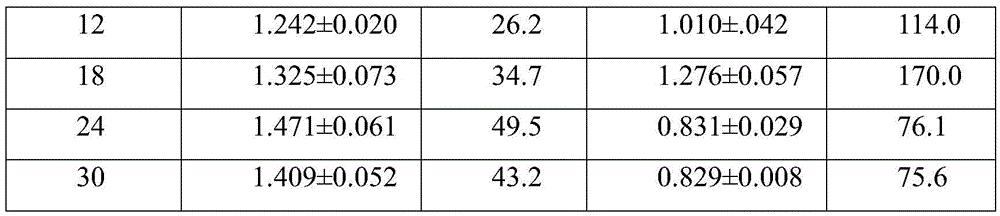

Examples

Embodiment 1

[0054] Select Tainong mangoes as raw materials, and proceed as follows:

[0055] 1) Cleaning of raw materials: select ripe fresh Tainong mangoes, remove the pits and skins, and cut into pieces to obtain mango pulp.

[0056] 2) Beating and extracting juice: adding water to beat the mango pulp (mango pulp: water = 1:3) to obtain the original mango juice.

[0057] 3) Color protection: refer to the GB2760-2011 food additive use standard, use ascorbic acid raw mango juice for color protection, and the amount of sodium ascorbate added is 5‰ of the original mango juice;

[0058] Seasoning: refer to the GB2760-2011 food additive use standard, use food additives to add sodium ascorbate to the original mango juice for seasoning, the final seasoning formula is to add 2.0g of white sugar and 0.1g of citric acid aqueous solution with a concentration of 20% to every 100mL of original mango juice , to get NFC mango juice.

[0059] 4), ultra-high pressure homogenization treatment: use bacte...

Embodiment 2

[0082] Select Tainong mangoes as raw materials, and proceed as follows:

[0083] (1) Cleaning of raw materials: select ripe fresh Tainong mangoes, remove the pits and skins, and cut them into pieces to obtain mango pulp.

[0084] (2) Beating and extracting juice: adding water to the mango pulp (mango pulp: water = 1:3) to obtain the original mango juice.

[0085] (3) Color protection: with reference to the GB2760-2011 standard for use of food additives, the original mango juice with ascorbic acid is used for color protection, and the amount of sodium ascorbate added is 5‰ of the original mango juice.

[0086] Seasoning: referring to the GB2760-2011 standard for the use of food additives, use food additives to season the original mango juice. The final seasoning formula is to add 2.0g of white sugar and 0.1g of citric acid aqueous solution with a concentration of 20% to every 100mL of original mango juice; get NFC mango juice.

[0087] (4), ultra-high pressure homogenization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com