Anion exchange membrane with acid blocking function and preparation method thereof

An anion-exchange membrane and ion-exchange membrane technology, applied in the field of ion-exchange membranes, can solve problems such as the attenuation of membrane acid resistance, and achieve the effects of long membrane life, simple operation, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

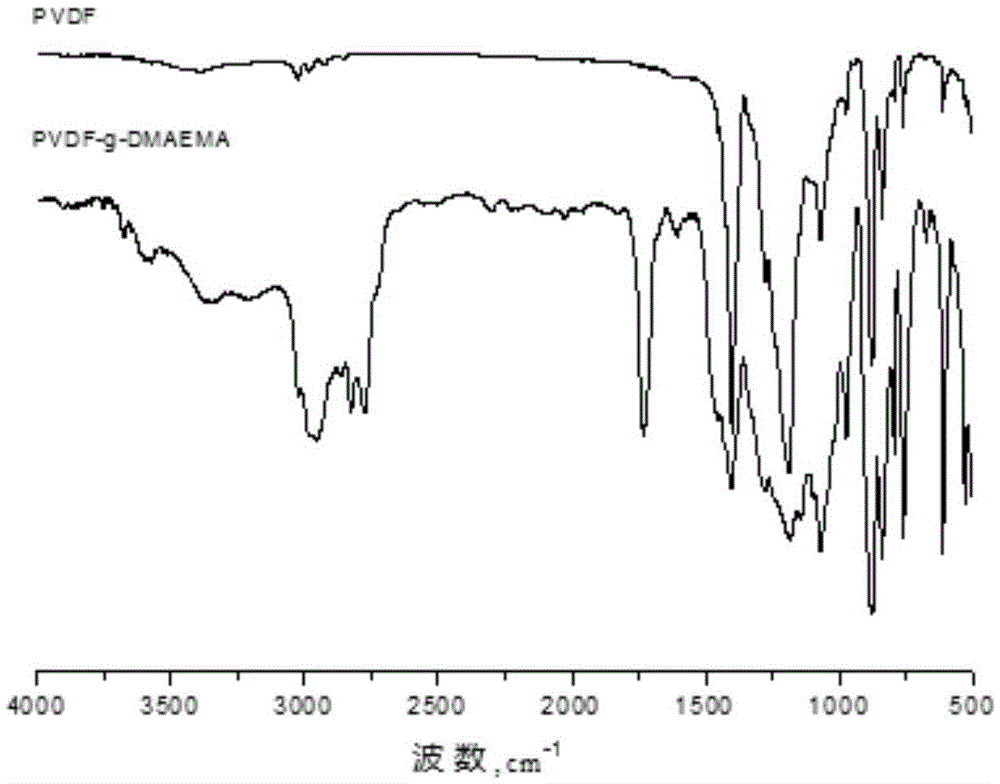

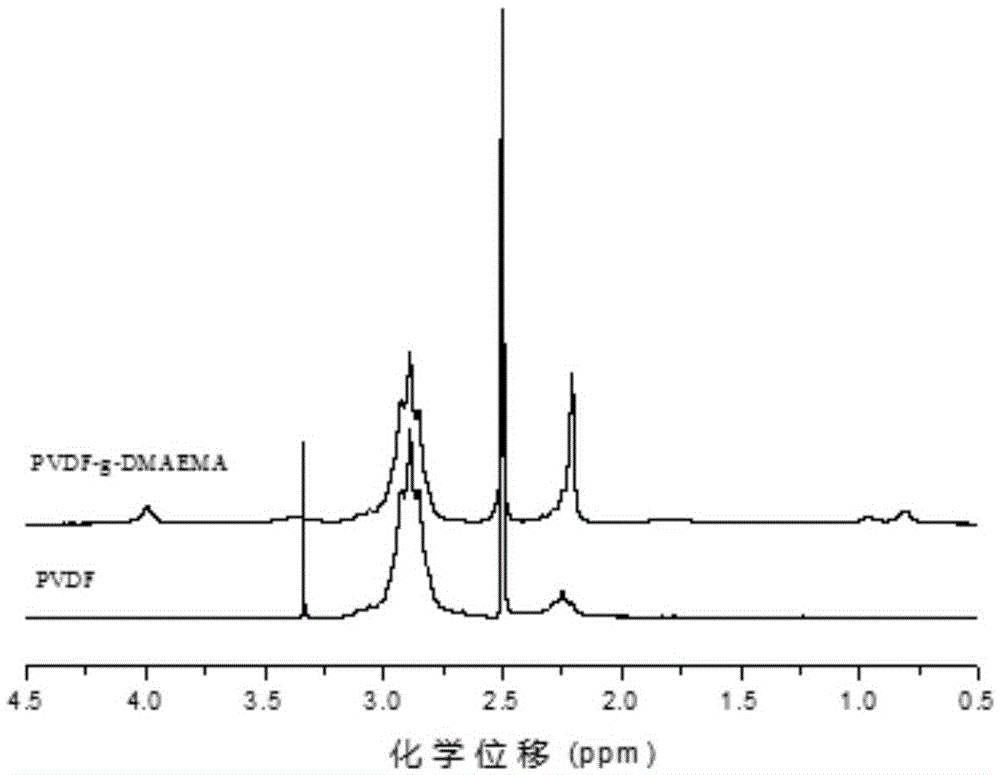

[0040] Add 700ml of 2.5mol / L KOH solution to 100g of polyvinylidene fluoride (PVDF) powder, stir and react at 60°C for 30 minutes, then suction filter, wash with pure water and vacuum dry in sequence to obtain polyvinylidene fluoride pretreated with alkali. Vinyl fluoride. Add an appropriate amount of the above alkali-treated polyvinylidene fluoride, dimethylaminoethyl methacrylate (DMAEMA) and azobisisobutyronitrile (AIBN) to dimethylacetamide, and the molar ratio of the three is 25: 25:1. Under nitrogen protection, react at 60° C. for 24 hours. The product PVDF-g-PDMAEMA was obtained by ethanol precipitation, and the precipitate was washed with ethanol and pure water several times after suction filtration, and then dried in vacuum for use. Infrared spectra of polyvinylidene fluoride and products ( figure 1 ) comparison, it can be seen that at wavenumber 2760cm -1 -2820cm -1 The new peaks that appear correspond to the -N(CH 3 ) 2 The stretching vibration of the methyl ...

Embodiment 2

[0044] Add 700ml of 2.5mol / l KOH solution to 100g of PVDF powder, stir and react at 60°C for 30 minutes, then suction filter, wash with pure water and vacuum dry in sequence to obtain alkali-pretreated polyvinylidene fluoride. Add an appropriate amount of alkali-treated polyvinylidene fluoride, vinylpyridine (VP) and azobisisobutyronitrile (AIBN) into dimethylacetamide, and the molar ratio of the three is 25:25:1. Under nitrogen protection, react at 60° C. for 24 hours. Precipitate the product PVDF-g-PVP with ethanol, wash the precipitate with ethanol and pure water several times after suction filtration, and dry it in vacuum for later use. The infrared spectrum of the product is as Figure 5 shown. Dissolve PVDF-g-PVP in dimethylformamide to prepare a casting solution with a concentration of 15%. After the casting solution is fully degassed, a liquid film with a thickness of 100 μm is scraped off, and the solvent is fully evaporated at 50° C. and then immersed in pure wate...

Embodiment 3

[0046] Add N-methylpyrrolidone to the PVDF powder to fully dissolve to obtain a 50g / L solution, and then add O 3 O at a concentration of 0.1 g / L 2 / O 3 Mixed gas was bubbled into it at a flow rate of 500 L / h for one hour. Subsequently, the N 2 20 minutes to remove the residual ozone in the system, then add an appropriate amount of DMAEMA (the molar ratio of DMAEMA to PVDF is 2:1) to the system, and stir and react at 60°C for 10 hours, then suction filter and wash with pure water and vacuum drying to obtain the product PVDF-g-PDMAEMA. PVDF-g-PDMAEMA was dissolved in N-methylpyrrolidone to prepare a casting solution with a concentration of 12%. After the casting solution is fully degassed, a liquid film with a thickness of 100 μm is scraped off, and the solvent is fully evaporated at 50° C. and then immersed in pure water to obtain an anion exchange membrane. at 30mA / cm 2 The constant current density electrodialysis concentration of 0.1M HCl is used as the evaluation syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com