Hierarchical pore Hbeta molecular sieve catalyst for preparing diphenylamine by condensing aniline as well as preparation method and application thereof

A technology of β molecular sieve and microporous molecular sieve, which is applied in the field of multi-level porous Hβ molecular sieve catalysts, can solve the problems of unfavorable catalyst activity, service life, product selectivity, catalyst activity decline, and loss of activity, so as to improve reaction rate and product selection High degree, high selectivity, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

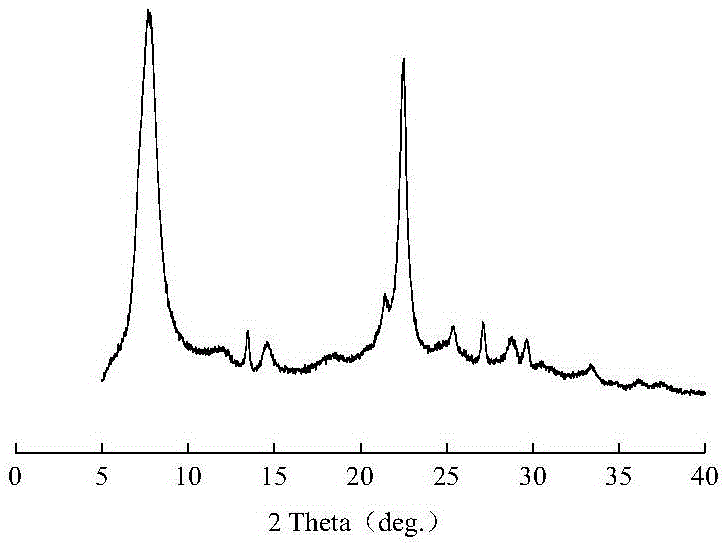

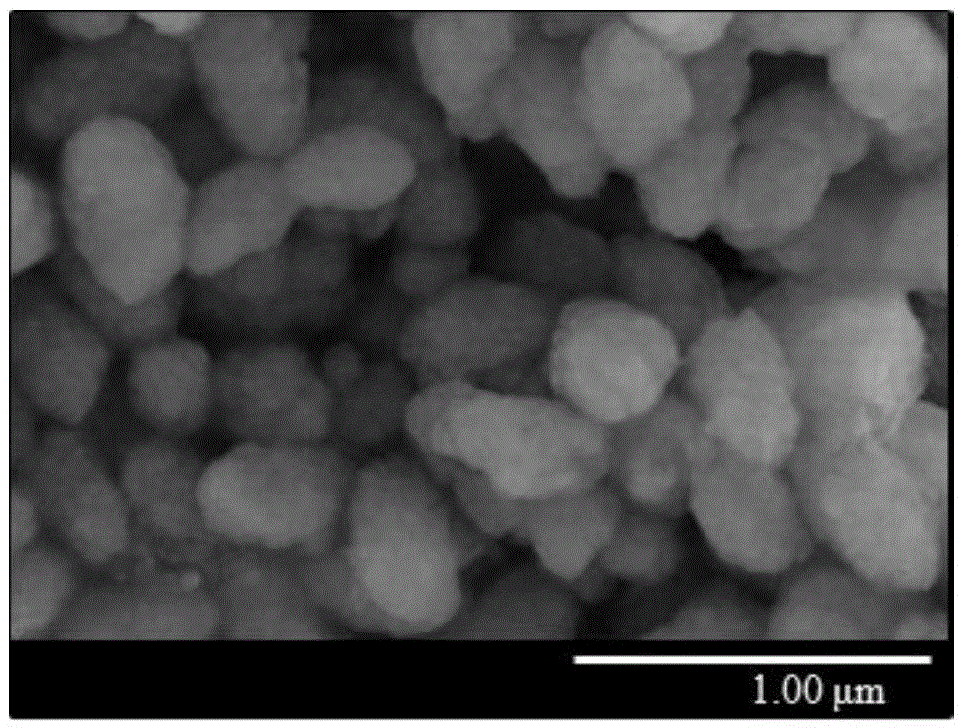

Embodiment 1

[0050] Dissolve 0.05g of NaCl and 0.15g of KCl in 20mL of water, add 14.4g of tetraethylammonium hydroxide aqueous solution (25% by mass) and 3.9g of silicic acid, stir at 40℃ for 4~5h, then add 0.547g of NaAlO 2 And 0.145g NaOH, the measured pH value is 12.2, continue to stir for 4-5h, then add 0.5g cetyltrimethylammonium bromide to it, and stir for 8-10h at 80°C. Put the formed white turbid liquid into the crystallization kettle, under the autogenous pressure, crystallize at 150°C for 120h, after the crystallization is finished, cool to room temperature naturally. The solid-liquid mixture was filtered to remove the liquid, washed to neutrality, and dried in an oven at 100°C for 12 hours. Then it was calcined at 550°C for 6 hours to obtain a multi-porous β molecular sieve. Take 4g of hierarchical pore β molecular sieve and 80mL of 1mol / L NH 4 The Cl solution was ion-exchanged 3 times, 4h each time, filtered, washed, dried, and calcined at 550°C for 6h to obtain a multi-porous ...

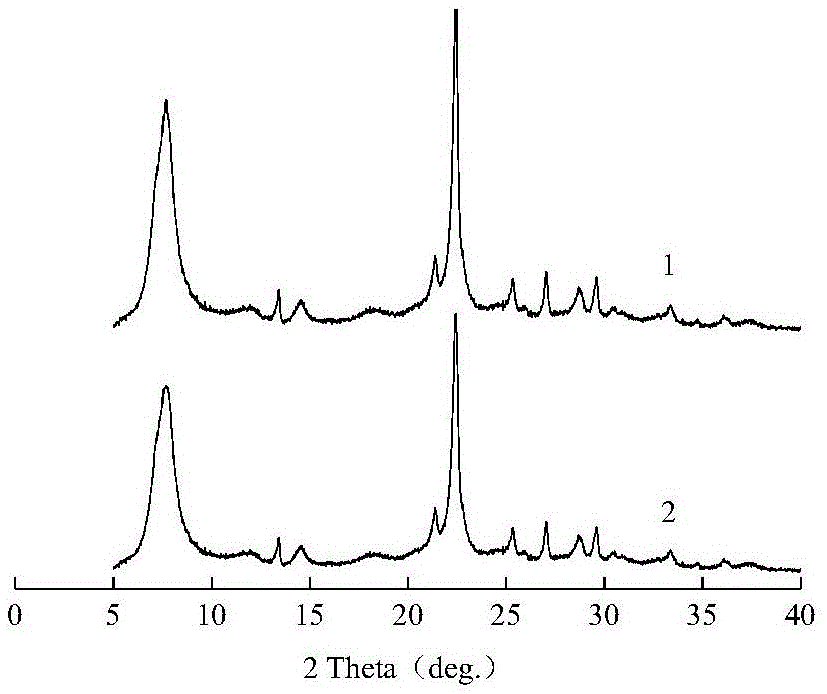

Embodiment 2

[0052] Dissolve 0.05g of NaCl and 0.15g of KCl in 20mL of water, add 14.4g of tetraethylammonium hydroxide aqueous solution (25% by mass) and 3.9g of silicic acid, stir at 40℃ for 4~5h, then add 0.164g of NaAlO 2 And 0.066g of NaOH, the measured pH value is 11.2, continue to stir for 4 to 5h, then add 0.5g of hexadecyltrimethylammonium bromide to it, and stir for 8 to 10h at 80°C. Put the formed white turbid liquid into the crystallization kettle, under the autogenous pressure, crystallize at 150°C for 120h, after the crystallization is finished, cool to room temperature naturally. The solid-liquid mixture was filtered to remove the liquid, washed to neutrality, and dried in an oven at 100°C for 12 hours. Then it was calcined at 550°C for 6 hours to obtain a multi-porous β molecular sieve. Take 4g of hierarchical pore β molecular sieve and 80mL of 1mol / L NH 4 The Cl solution was ion-exchanged 3 times, 4h each time, filtered, washed, dried, and calcined at 550°C for 6h to obtain...

Embodiment 3

[0054] Dissolve 0.05g of NaCl and 0.15g of KCl in 20mL of water, add 14.4g of tetraethylammonium hydroxide aqueous solution (25% by mass) and 3.9g of silicic acid, stir at 40°C for 4~5h, then add 0.055g of NaAlO 2 And 0.066g NaOH, the measured pH value is 10.9, continue to stir for 4-5h, then add 0.5g of hexadecyltrimethylammonium bromide to it, and stir for 8-10h at 80°C. Put the formed white turbid liquid into the crystallization kettle, under the autogenous pressure, crystallize at 150°C for 120h, after the crystallization is finished, cool to room temperature naturally. The solid-liquid mixture was filtered to remove the liquid, washed to neutrality, and dried in an oven at 100°C for 12 hours. Then it was calcined at 550°C for 6 hours to obtain a multi-porous β molecular sieve. Take 4g of hierarchical pore β molecular sieve and 80mL of 1mol / L NH 4 The Cl solution was ion-exchanged 3 times, 4h each time, filtered, washed, dried, and calcined at 550°C for 6h to obtain a multi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com