Preparation method for nanometer cuprous oxide particle, and morphology and particle size controlling method

A technology of nano-cuprous oxide and particles, applied in the direction of copper oxide/copper hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of complex preparation conditions, high production cost, and difficult control of the synthesis process, and achieve simplified preparation process, Good dispersion and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0041] In the present embodiment, the preparation method of nano cuprous oxide particles is as follows:

[0042] (1) 5.0 g of copper sulfate pentahydrate was formulated into 100 mL of solution, stirred at room temperature to fully dissolve the copper salt, and a solution of copper sulfate pentahydrate with a copper ion concentration of 0.2 mol / L was prepared.

[0043] (2) 3.2 g of sodium hydroxide was formulated into 100 mL of solution, stirred at room temperature to fully dissolve sodium hydroxide in water, and a sodium hydroxide alkaline solution with a concentration of 0.8 mol / L was prepared.

[0044] (3) 7.2 g of anhydrous glucose was formulated into 100 mL solution, stirred at room temperature to fully dissolve the glucose, and a glucose solution with a concentration of 0.4 mol / L was prepared.

[0045] (4) At room temperature, in 100mL0.2mol / L copper sulfate pentahydrate solution, add dropwise the sodium hydroxide solution that 100mL step (2) makes, and keep stirring, the...

Embodiment 1-2

[0049] In this example, the preparation method of nano-cuprous oxide particles is basically the same as that of Example 1-1, the difference is that in step (4), the dropping rate of reducing agent anhydrous glucose is controlled to 0.08mol / h, i.e. 30min The dropwise addition is complete.

[0050] The X-ray spectrogram of above-mentioned obtained particle is as Figure 10 As shown in curve 2, the particles are nano-cuprous oxide particles.

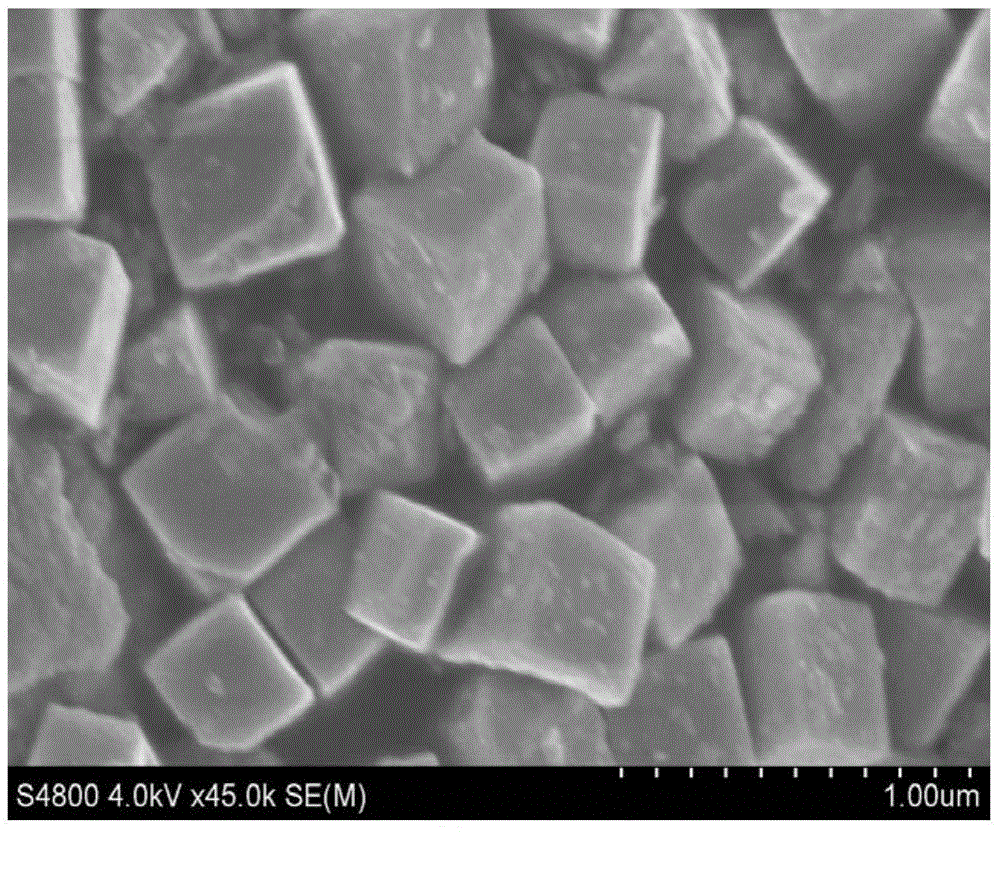

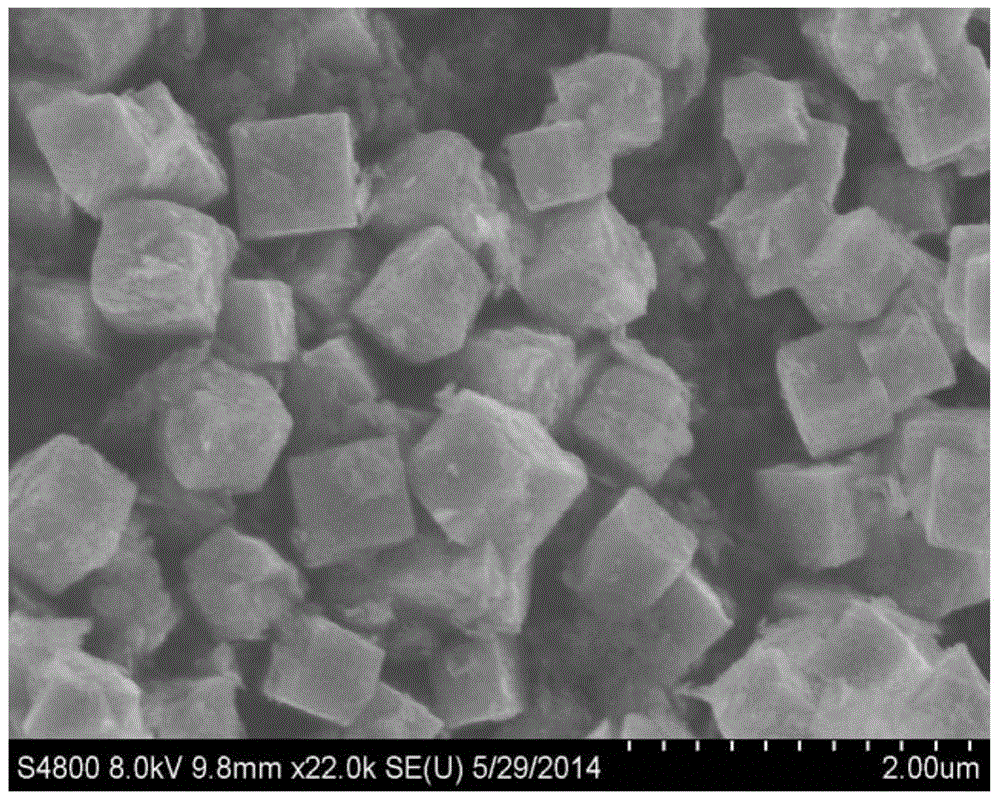

[0051] The scanning electron micrograph of the nano cuprous oxide particle that above-mentioned makes is as follows figure 2 ,Depend on figure 2 It can be seen that the nano-cuprous oxide particles are in the cubic crystal form, the average side length of the particles is 600 nm, and the particle size distribution is uniform.

Embodiment 1-3

[0053] In this example, the preparation method of nano-cuprous oxide particles is basically the same as that of Example 1-1, the difference is that in step (4), the dropping rate of reducing agent anhydrous glucose is controlled to 0.02mol / h, 120min drops Finished adding.

[0054] The X-ray spectrogram of above-mentioned obtained particle is as Figure 10 As shown in curve 3, the particles are nano-cuprous oxide particles.

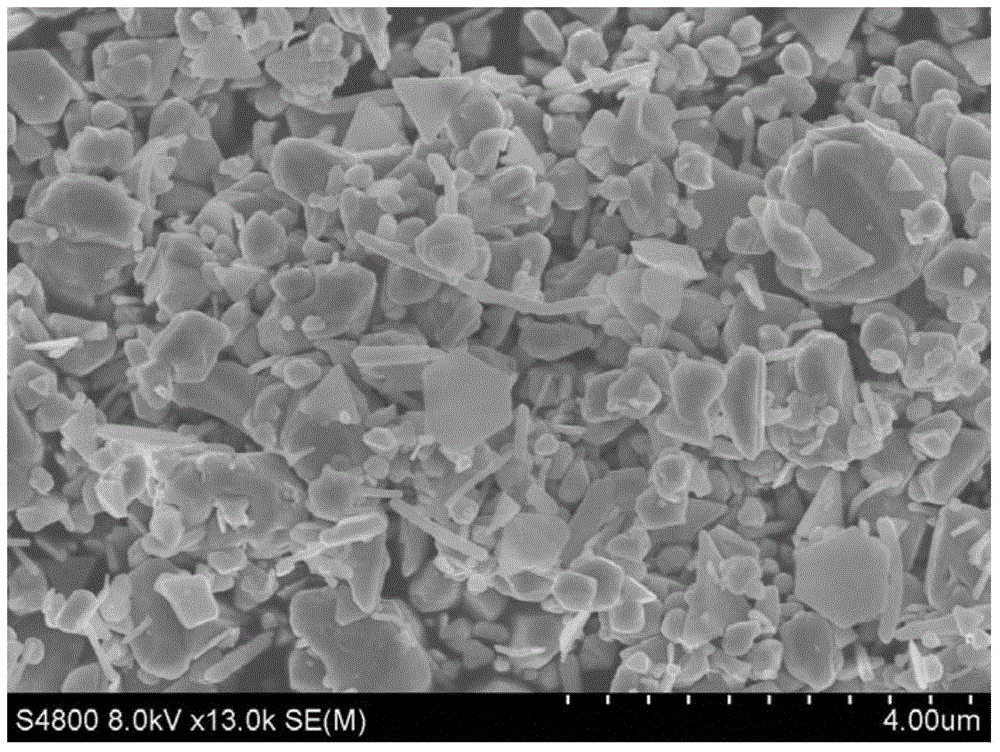

[0055] The scanning electron micrograph of the nano cuprous oxide particle that above-mentioned makes is as follows image 3 ,Depend on image 3 It can be seen that an amorphous state is formed because the addition rate of the reducing agent is too slow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average side length | aaaaa | aaaaa |

| Average side length | aaaaa | aaaaa |

| Average side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com