Preparation method of copolymer

A copolymer and unsaturated technology, which is applied in the field of copolymers, can solve problems such as the degree of hydrogenation of hydrogenation products needs to be improved, the cost of catalyst application is high, and the activity of hydrogenation reaction is low, so as to reduce the preparation cost, shorten the reaction time, improve The effect of hydrogenation reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The invention provides a kind of preparation method of copolymer, and this method comprises the following steps:

[0016] (1) dissolving the unsaturated copolymer in an organic solvent to obtain a glue solution, which is filled and degassed;

[0017] (2) Add catalyst and ligand for hydrogenation, the catalyst for hydrogenation has the following general formula: (R m A) z wxya n , wherein, each R is independently selected from C1-C8 alkyl, C4-C8 cycloalkyl, C6-C15 aryl or C7-C15 aralkyl; A is selected from phosphorus, arsenic, sulfur or sub Sulfone group S=O; X is selected from hydrogen or anion; z is 2, 3 or 4; m is 2 or 3; n is 1, 2 or 3;

[0018] (3) Filling with hydrogen, stirring, and reacting, the conditions of the reaction include: the reaction temperature is 0-30°C, the hydrogen pressure is 0.05-15Mpa, and the reaction time is 1-120 minutes;

[0019] (4) heating up to 50-180°C, keeping the hydrogen pressure at 0.1-15Mpa, and reacting for 1-20 hours;

[0020]...

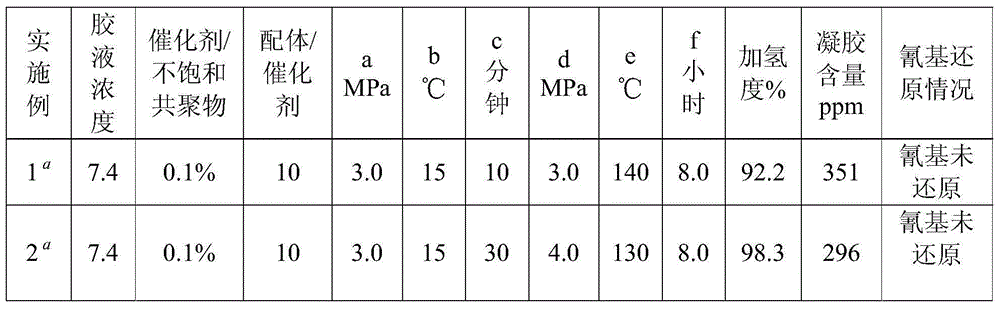

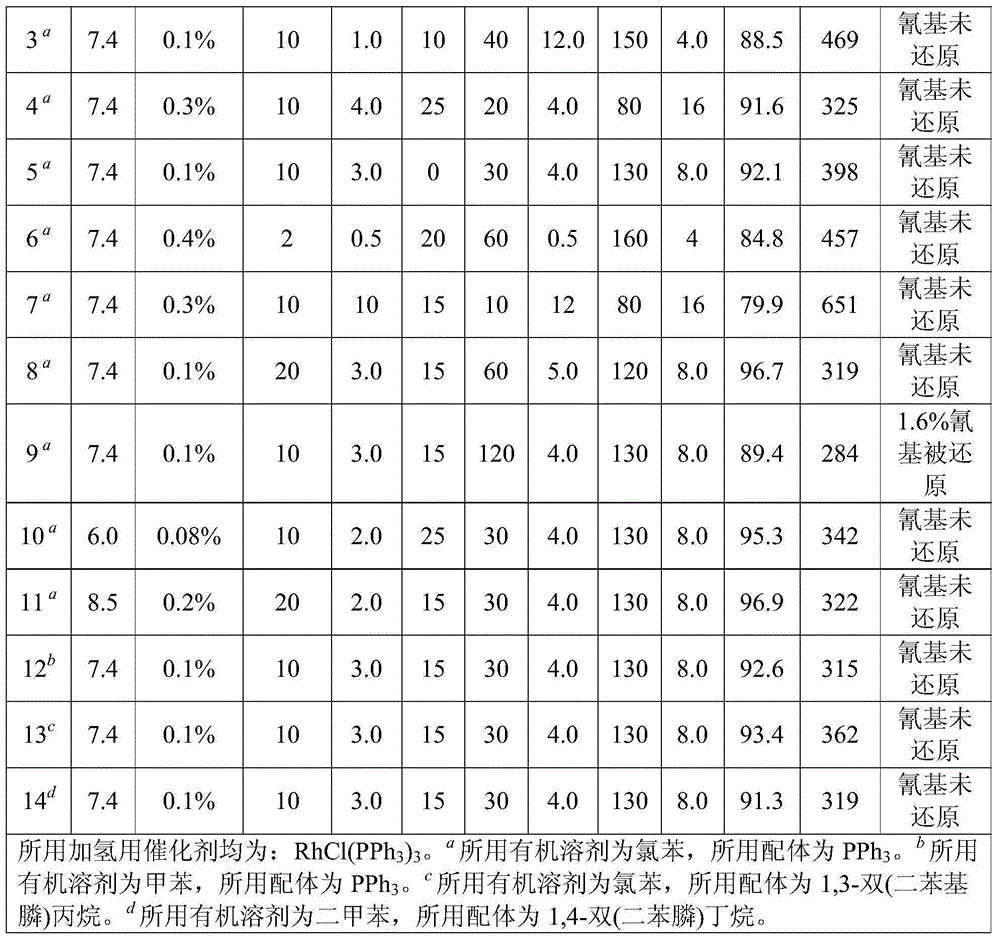

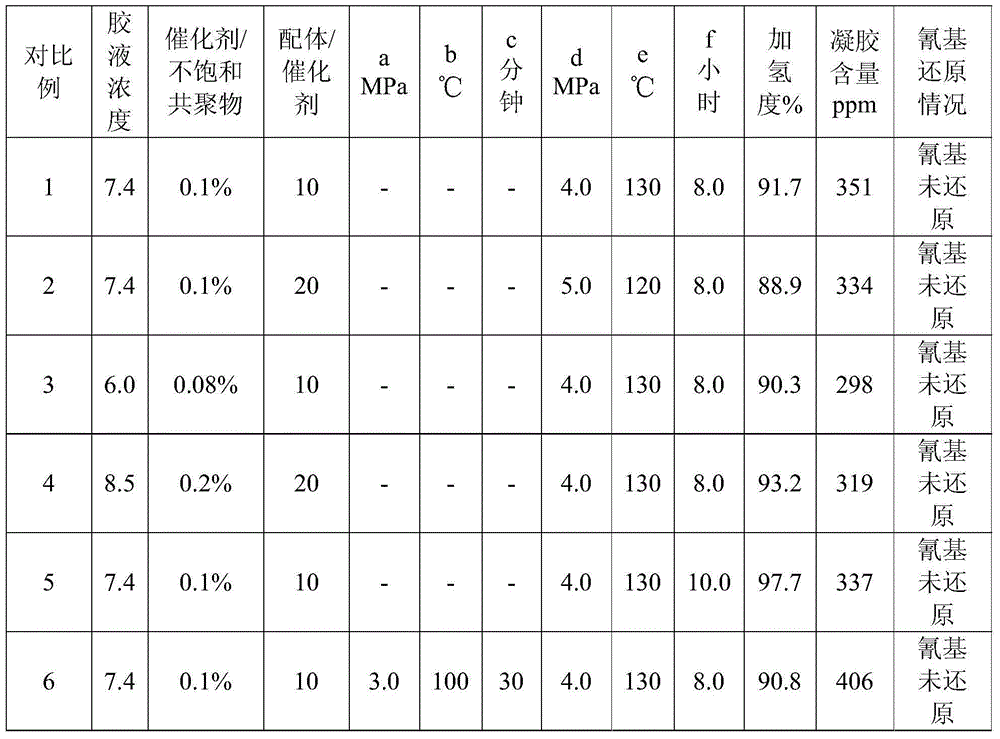

Embodiment 1-14

[0040] Embodiment 1-14 of the present invention is used to illustrate the preparation method of copolymer of the present invention:

[0041] (1) dissolving the unsaturated copolymer in an organic solvent to obtain a glue solution, which is added to the reaction kettle, and degassed;

[0042] (2) Add hydrogenation catalyst and ligand;

[0043] (3) Filling with hydrogen, stirring, and reacting, the conditions of the reaction include: the reaction temperature is b°C, the hydrogen pressure is aMPa, and the reaction time is c minutes;

[0044] (4) be warming up to e ℃, keep the hydrogen pressure as dMPa, and react for f hours;

[0045] (5) The hydrogenated product was condensed and precipitated by ethanol, and dried in vacuum at 60° C. for 8 hours.

[0046] In embodiment 1-14, unsaturated copolymer is all butadiene-acrylonitrile rubber, and the gel content of butadiene-acrylonitrile rubber is 304ppm, and the quality of glue solution is 540g, and glue solution concentration (i.e. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com