A kind of cobalt, the method for ammonia catalysis thiosulfate leaching gold

A technology of thiosulfate and sulfosulfate, which is applied in the field of hydrometallurgy, can solve the problems of large leaching agent consumption, slow gold leaching speed, and poor gold leaching effect, and achieve simple leaching liquid components, easy recovery, and low consumption. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

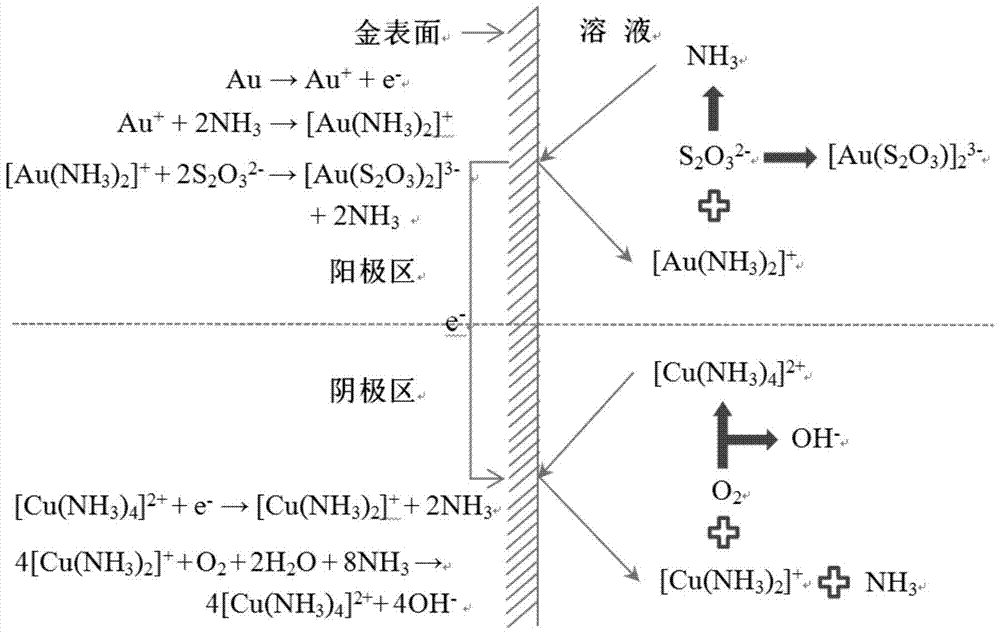

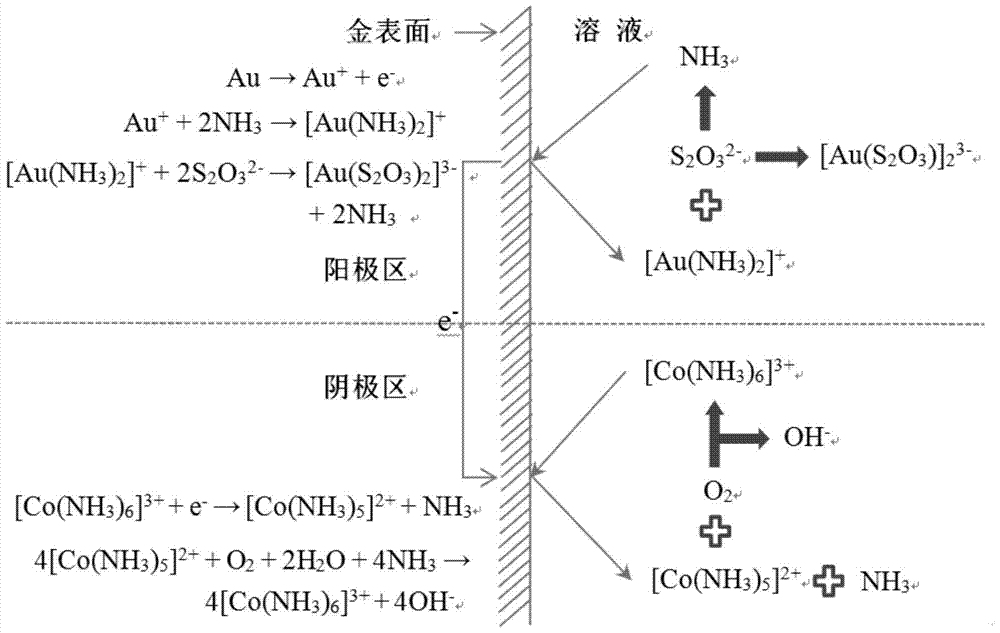

Method used

Image

Examples

Embodiment 1

[0026] Example 1: In the pulp as described in Comparative Example 1, add cobalt sulfate, ammonia water, and sodium thiosulfate to 0.01mol / L, 0.3mol / L, and 0.1mol / L successively, and then adjust the pulp with sodium hydroxide pH is 9.0, and other leaching conditions are leached for 4.0h under the same conditions as in Comparative Example 1, the leaching rate of gold is 89.1%, and the consumption of sodium thiosulfate is 5.26kg / t 原料 .

Embodiment 2

[0027] Embodiment 2: In the pulp as described in Comparative Example 1, add cobalt sulfate, ammoniacal liquor, sodium thiosulfate respectively to 0.03mol / L, 0.7mol / L, 0.5mol / L successively, then adjust the pulp with sodium hydroxide The pH is 10.0, and other leaching conditions are leached for 8.0h under the same conditions as that of Comparative Example 1, the leaching rate of gold is 90.9%, and the consumption of sodium thiosulfate is 5.76kg / t 原料 .

Embodiment 3

[0028] Embodiment 3: In the ore pulp as described in Comparative Example 1, add cobalt sulfate, ammoniacal liquor, ammonium thiosulfate respectively to 0.05mol / L, 1.0mol / L, 1.0mol / L successively, then adjust the ore pulp with sodium hydroxide pH is 11.0, and other leaching conditions are leached for 12.0h under the same conditions as in Comparative Example 1, the leaching rate of gold is 91.8%, and the consumption of ammonium thiosulfate is 7.24kg / t 原料 .

[0029] Raw material condition 2: The raw material is calcined sand obtained by oxidizing and roasting a certain high-sulfur and high-arsenic gold concentrate. %, 0.55%, 0.25%, 0.24%, 0.09%. Its mineral composition is mainly hematite and quartz. Table 2 is the gold chemical phase analysis results of the calcine.

[0030] Table 2 Chemical phase analysis results of gold in calcine

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com