High-strength and high-tenacity zinc alloy bar/wire and preparation method thereof

A technology of alloy rods and alloy wires, applied in the field of high-strength and tough zinc alloy rods/wires and their preparation, can solve problems such as stress corrosion, dimensional instability, aging failure, etc., and achieve the effect of improving strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

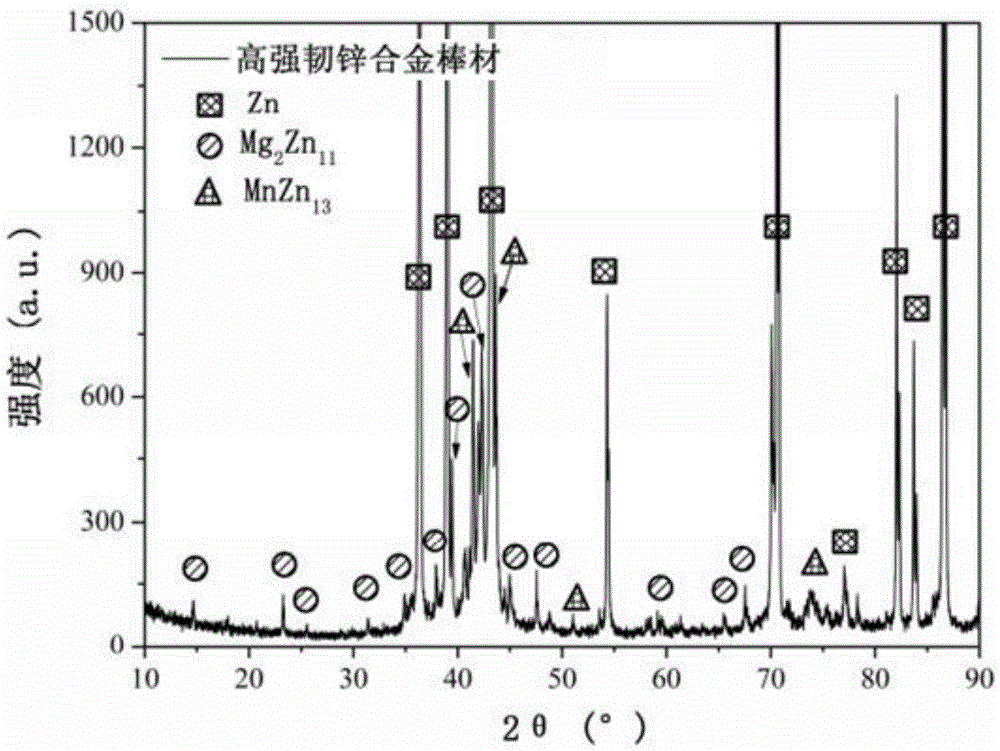

[0046] High-strength and tough zinc alloy rod / wire, the components are: Mn: 0.8%, Mg: 0.18%, unavoidable impurities ≤ 0.3%, and the balance is Zn.

[0047] The preparation method of high strength and toughness zinc alloy comprises the following steps:

[0048] Step 1, melting and casting: weigh the ingredients according to the mass percentage of the high-strength and tough zinc alloy; heat the pure metal zinc to 550°C in a graphite crucible, add metal magnesium and metal manganese in turn after all the metals are melted, and stir until all the metals are melted. Mix evenly to obtain a zinc alloy melt; reduce the temperature of the melt to 480°C, and use a graphite bell jar to add hexachloroethane to the melt, and the amount of hexachloroethane added is 0.35% of the mass of the melt , and then kept at 480°C for 20 minutes; the melt temperature was lowered to 440°C for casting, and the mold was cooled by water during the casting process to obtain a cylindrical ingot with a diame...

Embodiment 2

[0055] High-strength and tough zinc alloy rods / wires, the components are: Mn: 2%, Mg: 1%, unavoidable impurities ≤ 0.3%, and the balance is Zn;

[0056] The preparation method of high strength and toughness zinc alloy comprises the following steps:

[0057] Step 1, melting and casting: weigh the ingredients according to the mass percentage of the high-strength and tough zinc alloy; heat the pure metal zinc to 550°C in a graphite crucible, add metal magnesium and metal manganese in turn after all the metals are melted, and stir until all the metals are melted. Mix evenly to obtain a zinc alloy melt; reduce the temperature of the melt to 480° C., add hexachloroethane to the melt by using a graphite bell jar, and the addition amount of hexachloroethane is 0.4% of the melt mass , and then kept at 480 °C for 20 minutes; the melt temperature was lowered to 460 °C, and casting was performed. During the casting process, the mold was cooled by water to obtain a cylindrical ingot with a...

Embodiment 3

[0064] High strength and toughness zinc alloy rod / wire, the components are: Mn: 0.5%, Mg: 0.05%, unavoidable impurities ≤ 0.3%, and the balance is Zn.

[0065] The preparation method of high strength and toughness zinc alloy comprises the following steps:

[0066] Step 1, melting and casting: weigh the ingredients according to the mass percentage of the high-strength and tough zinc alloy; heat the pure metal zinc to 550°C in a graphite crucible, add metal magnesium and metal manganese in turn after all the metals are melted, and stir until all the metals are melted. Mix evenly to obtain a zinc alloy melt; reduce the temperature of the melt to 480° C., add hexachloroethane to the melt by using a graphite bell jar, and the addition amount of hexachloroethane is 0.45% of the melt mass , and then kept at 480 °C for 15 minutes; the melt temperature was reduced to 450 °C, and casting was performed. During the casting process, the mold was cooled by water to obtain a cylindrical ingo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com