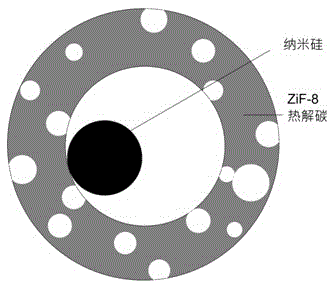

Method for preparing hollow porous composite silicon-carbon material

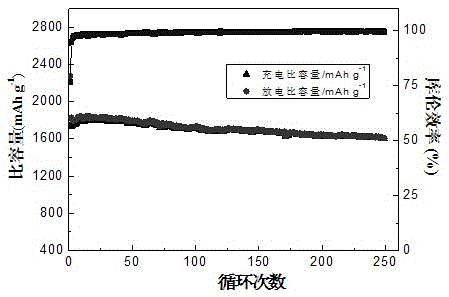

A silicon carbon material, hollow technology, applied in the field of electrochemistry, can solve the problems of poor conductivity of silicon materials, unstable SEI film, loss of electrical contact, etc., achieve good cycle performance and specific capacity, cheap and easy to obtain raw materials, and simple synthesis method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve 50mg of PVP in 2ml of deionized water, add 5mg of commercial nano-silicon particles, ultrasonicate for 10min, and centrifuge to obtain PVP-coated nano-silicon particles; in 5ml of 0.1M CuCl 2 Add 0.1 mg of the above nano-silicon particles to the deionized aqueous solution, and then add 2.5 ml of 0.5 M NaOH aqueous solution and 2 ml of 0.1 M NH 2 OHHCl aqueous solution, shake the solution to mix the solution evenly. Stand at room temperature for 4h until the solution turns from yellowish brown to brownish green. Centrifuge, wash twice with methanol; dissolve 10mg of Zn(NO 3 ) 2 And stir quickly under the ice bath, then add 2ml of Pd-Cu 2 To a methanolic suspension (0.1 M) of O particles was added 30 mg of 2-methylimidazole, and the two solutions were mixed rapidly. Stir under ice bath for 2 hours, then at room temperature for 1 hour. Wash with 3% methanol solution of ammonium hydroxide to remove residual cuprous oxide. At this time, the solution returns to ...

Embodiment 2

[0026] Dissolve 100mg of CTAB in 2ml of deionized water, add 10mg of commercial nano-silicon particles, ultrasonicate for 10min, and centrifuge to obtain CTAB-coated nano-silicon particles; in 5ml of 0.1M CuCl 2 Add 0.3mg of the above nano-silicon particles to the deionized aqueous solution, and then add 4ml of 0.5M NaOH aqueous solution and 6ml of 0.1M NH 2 OH?HCl aqueous solution, shake the solution to mix the solution evenly. Stand at room temperature for 3h until the solution turns from yellowish brown to brownish green. Centrifuge, wash twice with ethanol; dissolve 10 mg of Zn(NO 3 ) 2 And stir quickly under the ice bath, then add 8ml of Pd-Cu 2 To an ethanol suspension (1 M) of O particles was added 80 mg of 2-methylimidazole, and the two solutions were mixed rapidly. Stir for 3 hours in the ice bath, then for 1 hour at room temperature. Wash with 3% ethanol solution of ammonium hydroxide to remove residual cuprous oxide, at this time the solution returns to yellowi...

Embodiment 3

[0028] Dissolve 100mg of PVP in 2ml of deionized water, add 20mg of commercial nano-silicon particles, ultrasonicate for 60min, and centrifuge to obtain PVP-coated nano-silicon particles; in 5ml of 2M CuCl 2 Add 0.6mg of the above nano-silicon particles to the deionized aqueous solution, and then add 8ml of 1.5M NaOH aqueous solution and 12ml of 0.9M NH 2 OH?HCl aqueous solution, shake the solution to mix the solution evenly. Stand at room temperature for 5h until the solution turns from yellowish brown to brownish green. Centrifuge, wash twice with tetrahydrofuran; dissolve 9 mg of Zn(NO 3 ) 2 And stir quickly under the ice bath, then add 14ml of Pd-Cu 2 To an ethanol suspension (1.5 M) of O particles was added 90 mg of 2-methylimidazole, and the two solutions were mixed rapidly. Stir for 3 hours in the ice bath, then 1.5 hours at room temperature. Wash with 3% methanol solution of ammonium hydroxide to remove residual cuprous oxide, at this time the solution returns to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com