Preparation method of mesoporous carbon material

A mesoporous carbon and mesoporous technology, applied in the field of preparation of mesoporous carbon materials, can solve the problems of high preparation cost and unfavorable industrial production, and achieve the effect of low production cost and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Mix 1g of calcium carbonate with 15mL of ethanol, stir for 10min, add 30mL of distilled water, 4g of sucrose, 20mL of silica sol, and stir for 1h;

[0035] (2) ultrasonically treating the mixture obtained in step (1) for 5 hours;

[0036] (3) Put the mixture prepared in step (2) in a water bath and stir at 70°C to evaporate the water until the mixture becomes viscous;

[0037] (4) Dry the mixture prepared in step (3) at 70°C, and then place it in a tube furnace with nitrogen at a flow rate of 30mL / min; heat up from room temperature to 900°C at 5°C / min, and keep 5h;

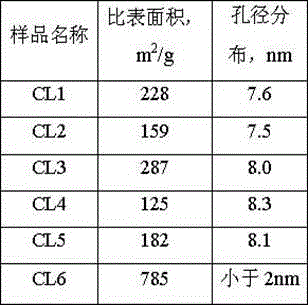

[0038] (5) Mix the substance obtained in step (4) with 50mL of 50% hydrochloric acid solution, treat at 150°C for 5h, then wash with water until neutral; then mix with 50mL of 20% sodium hydroxide solution, Treated under the same conditions for 5 hours, washed with water again until neutral, and finally dried at 100°C for 10 hours to prepare a mesoporous carbon material, coded as CL1. The results of t...

Embodiment 2

[0040] (1) Mix 1.5g calcium carbonate with 25mL ethanol, stir for 10min, add 30mL distilled water, 3.5g sucrose, 20mL silica sol, stir for 1h;

[0041] (2) ultrasonically treating the mixture obtained in step (1) for 4 hours;

[0042] (3) Put the mixture prepared in step (2) in a water bath and stir at 60°C to evaporate the water until the mixture becomes viscous;

[0043](4) Dry the mixture prepared in step (3) at 70°C, and then place it in a tube furnace with nitrogen at a flow rate of 30mL / min; heat up from room temperature to 850°C at 5°C / min, and keep 5h;

[0044] (5) Mix the substance obtained in step (4) with 50mL of 50% hydrochloric acid solution, treat at 150°C for 5h, then wash with water until neutral; then mix with 50mL of 20% sodium hydroxide solution, Treated under the same conditions for 5 hours, washed with water again until neutral, and finally dried at 100°C for 10 hours to prepare a mesoporous carbon material, coded as CL2. The results of the pore size dis...

Embodiment 3

[0046] (1) Mix 2g calcium carbonate with 15mL ethanol, stir for 10min, add 50mL distilled water, 5g sucrose, 20mL silica sol, stir for 1h;

[0047] (2) The mixture obtained in step (1) was ultrasonically treated for 7 h.

[0048] (3) Put the mixture prepared in step (2) in a water bath and stir at 70°C to evaporate the water until the mixture becomes viscous;

[0049] (4) Dry the mixture prepared in step (3) at 70°C, and then place it in a tube furnace with nitrogen at a flow rate of 30mL / min; heat up from room temperature to 750°C at 3°C / min, and keep 5h;

[0050] (5) Mix the substance obtained in step (4) with 50mL of 50% hydrochloric acid solution, treat at 160°C for 5h, then wash with water until neutral; then mix with 50mL of 20% sodium hydroxide solution, Treated under the same conditions for 5 hours, washed with water again until neutral, and finally dried at 100°C for 10 hours to prepare a mesoporous carbon material, coded as CL3. The results of the pore size distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com