Functionalized meso-porous silia-based material and preparation method and application thereof

A technology of mesoporous silicon and functionalization, which is applied in the field of functionalized mesoporous silicon-based materials. Large size, rich mesopores, outstanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

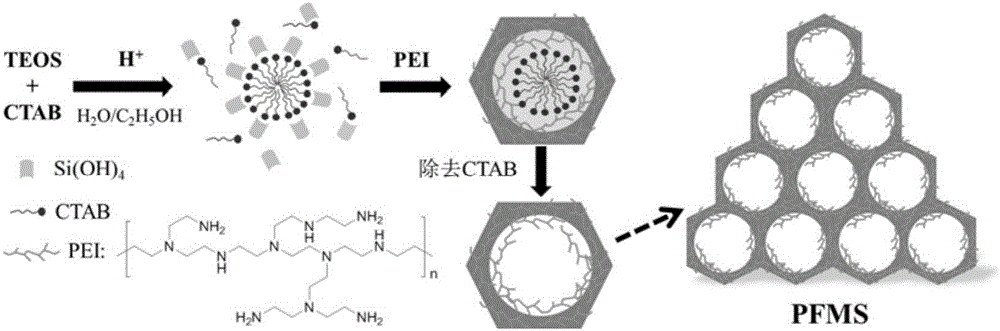

[0040] A functionalized mesoporous silicon-based material, the steps of its preparation method are as follows:

[0041]The first step: Dissolve 0.5g cetyltrimethylammonium bromide in a mixed solution of 7.5mL ethanol and 7.5mL deionized water, then add 15g ethyl orthosilicate (ethyl orthosilicate and hexadecane The molar ratio of base trimethylammonium bromide is 52.6:1), and 0.2mL concentrated phosphoric acid is added dropwise; Stir at room temperature for 2h to obtain the solution after the pre-hydrolysis reaction;

[0042] Step 2: Add 3 g of an aqueous solution of 50 wt % polyethyleneimine to the solution after the prehydrolysis reaction obtained in the first step to initiate co-condensation and co-precipitation reactions of organic components and inorganic components in the system, and then stir for 3 h; After the reaction, the resulting solid product was filtered out and washed with deionized water and ethanol to obtain a crude product;

[0043] The third step: in order ...

Embodiment 2

[0045] The difference between this example and Example 1 lies in that the addition amount of the aqueous solution of 50wt% polyethyleneimine is 6g.

Embodiment 3

[0047] The difference between this example and Example 1 lies in that the amount of the aqueous solution of 50 wt % polyethyleneimine added is 9 g.

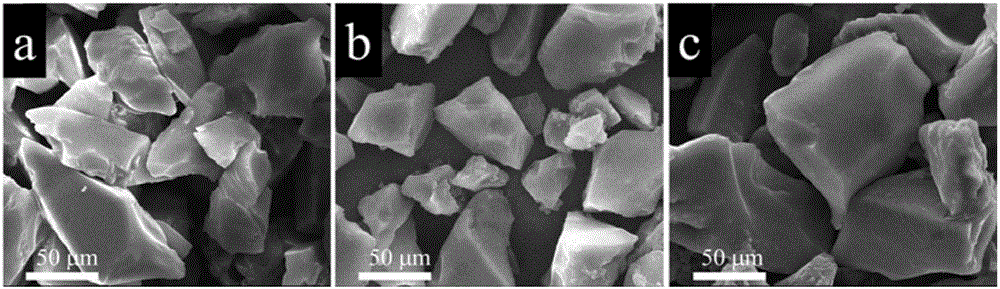

[0048] The functionalized mesoporous silicon-based material prepared in Examples 1 to 3 was characterized by a scanning electron microscope, and the results were as follows figure 2 shown, where figure 2 a, 2b, and 2c respectively correspond to Examples 1-3, and it can be known that the functionalized mesoporous silicon-based materials obtained in Examples 1-3 have different polyethyleneimine contents, but they all consist of particles of 20-100 μm.

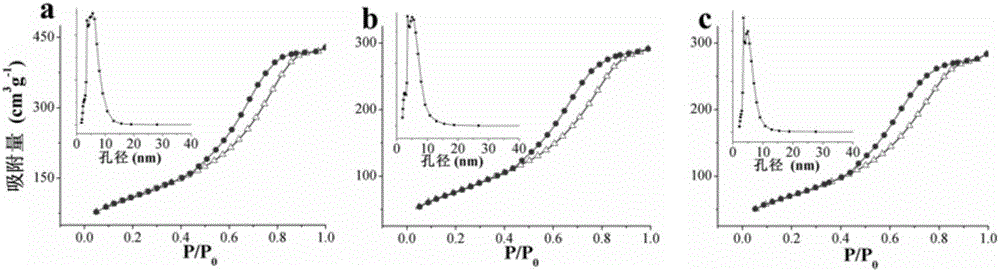

[0049] Carry out nitrogen adsorption / desorption test to the functionalized mesoporous silicon-based material prepared in embodiment 1-3, the result is as follows image 3 As shown, the nitrogen adsorption / desorption isotherms are all type IV, indicating that the functionalized mesoporous silicon-based materials obtained in Examples 1-3 have typical mesoporous structure characteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com