Energy-saving quick dewatering method of argillaceous biomass refuse

A biomass and mud technology, which can be used in energy and wastewater treatment, polluted waterway/lake/pond/river treatment, dehydration/drying/concentrated sludge treatment, etc., which can solve the problem of low efficiency and low solar heat utilization efficiency. , the slow drying speed of solar energy, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

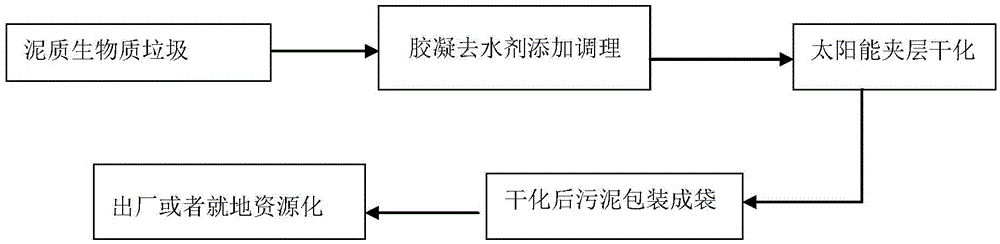

Method used

Image

Examples

Embodiment 1

[0041] According to the formula of the gelling dehydrating agent, the gelling dehydrating agent is composed of magnesium oxide, cationic polymer, CaO and ferric chloride uniformly mixed, and its mass ratio is 25%: 40%: 25%: 10%, and then mixed with The muddy biomass waste is mixed, and the dosage of the gelling water-removing agent is 5% of the sludge dry basis mass of the muddy biomass waste after dehydration, wherein the water content of the muddy biomass waste is 80%. , mixed evenly, pumped in with a high-pressure pump, uniformly distributed in the solar interlayer drying system, and dried under normal sunlight conditions. It takes 2 days for the % to decrease to 20% (the actual effective time is 18 hours), and the simple solar drying without adding gelling dehydrating agent needs 3.5 days to achieve the same effect (the actual sunlight irradiation time is 32 hours). The moisture content was tested using the "Testing Methods for Sludge from Municipal Sewage Treatment Plants...

Embodiment 2

[0043] According to the formula of the gelling dehydrating agent, the gelling dehydrating agent is composed of magnesium oxide, cationic polymer, CaO and ferric chloride uniformly mixed, and its mass ratio is 60%: 20%: 10%: 10%, and then mixed with The muddy biomass waste is mixed, and the dosage of the gelled water-removing agent is 10% of the sludge dry basis mass of the muddy biomass waste after dehydration, wherein the water content of the muddy biomass waste is 88%. , mixed evenly, injected with a high-pressure pump, evenly distributed in the solar interlayer drying system, and dried under normal sunlight conditions. It takes 2 days for the % to decrease to 20% (the actual effective time is 24 hours), while the simple solar drying without adding gelling dewatering agent needs 4 days to achieve the same effect (the actual sunlight irradiation time is 36 hours). The moisture content was tested using the "Testing Methods for Sludge from Municipal Sewage Treatment Plants" (CJ...

Embodiment 3

[0045] According to the formula of the gelling dehydrating agent, the gelling dehydrating agent is composed of magnesium chloride, cationic polymer, CaO and ferric chloride, and its mass ratio is 35%: 30%: 15%: 20%. The amount of the gelled water-removing agent is 15% of the sludge dry weight of the dehydrated muddy biomass waste, wherein the water content of the muddy biomass waste is 92%. Mix evenly, spread evenly in the solar interlayer drying system with a screw feeder, dry under normal sunlight conditions, the temperature in the interlayer fluctuates between 38-80°C during the day, and the moisture content of muddy biomass waste is from 92% The time required to reduce to 20% is 2 days (the actual effective time is 24 hours), while the simple solar drying without adding gelling dewatering agent needs 4 days to achieve the same effect (the actual sunlight irradiation time is 44 hours). The moisture content was tested using the "Testing Methods for Sludge from Municipal Sewa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com