Graphite composite cathode and preparation method thereof

A composite cathode and graphite technology, which is applied in the field of graphite composite cathode and its preparation, can solve problems such as limitations, and achieve the effects of long service life, good uniformity, and simple and convenient preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A graphite composite cathode of the present invention is specifically a large aspect ratio carbon fiber doped graphite composite cathode, and the graphite composite cathode is prepared from graphite powder, carbon fiber and medium-temperature pitch.

[0041] In this embodiment, based on the mass fraction, the content of graphite powder is 70%, the content of carbon fiber is 5%, and the content of medium-temperature pitch is 25%.

[0042] In this embodiment, the graphite powder used in the graphite composite cathode is 200 mesh flake graphite powder.

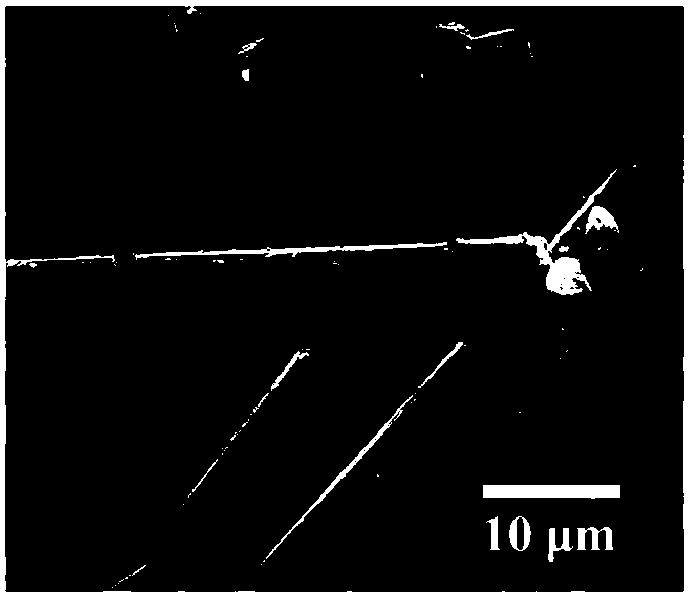

[0043] In this embodiment, the carbon fiber used in the graphite composite cathode is chopped carbon fiber, which passes through a 400-mesh sieve, has a diameter of about 7 μm, and a length of 20 to 200 μm. The microscopic appearance of the chopped carbon fiber is as follows: figure 2 shown.

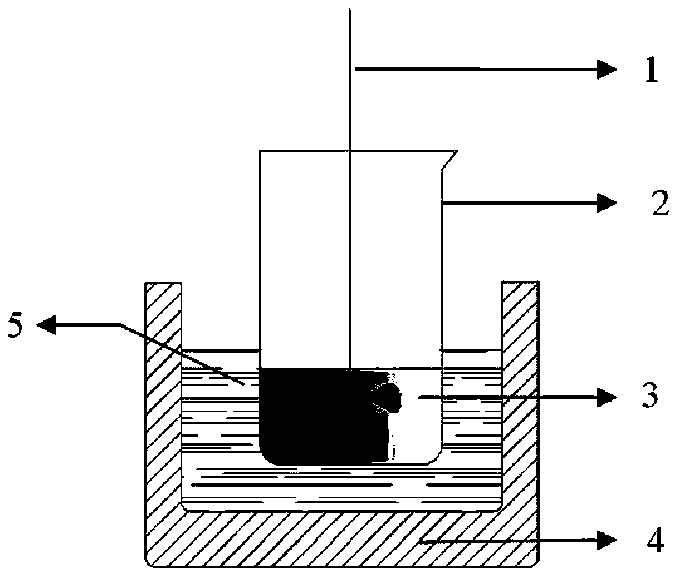

[0044] A method for preparing the graphite composite cathode of the above-mentioned present embodiment, comprising the following st...

Embodiment 2

[0054] A graphite composite cathode of the present invention is specifically a large aspect ratio carbon fiber doped graphite composite cathode, and the graphite composite cathode is prepared from graphite powder, carbon fiber and medium-temperature pitch.

[0055] In this embodiment, based on the mass fraction, the content of graphite powder is 72.5%, the content of carbon fiber is 2.5%, and the content of medium-temperature pitch is 25%.

[0056] In this embodiment, the graphite powder used in the carbon fiber-doped graphite composite cathode is 200 mesh flake graphite powder.

[0057] In this embodiment, the carbon fibers used in the carbon fiber-doped graphite composite cathode are chopped carbon fibers, which pass through a 400-mesh sieve, have a diameter of 7 μm, and a length of about 20-200 μm.

[0058] A method for preparing the graphite composite cathode of the above-mentioned present embodiment, comprising the following steps:

[0059] (1) Ingredients of cathode mat...

Embodiment 3

[0066] A graphite composite cathode of the present invention is specifically a large aspect ratio carbon fiber doped graphite composite cathode, and the graphite composite cathode is prepared from graphite powder, carbon fiber and medium-temperature pitch.

[0067] In this embodiment, based on the mass fraction, the content of graphite powder is 65%, the content of carbon fiber is 10%, and the content of medium-temperature pitch is 25%.

[0068] In this embodiment, the graphite powder used in the carbon fiber-doped graphite composite cathode is 400 mesh flake graphite powder.

[0069] In this embodiment, the carbon fibers used in the carbon fiber-doped graphite composite cathode are chopped carbon fibers, which pass through a 400-mesh sieve, have a diameter of 7 μm, and a length of about 20-200 μm.

[0070] A method for preparing the graphite composite cathode of the above-mentioned present embodiment, comprising the following steps:

[0071] (1) Ingredients of cathode materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com