Method for removing residual acids in biosaccharide preparation technique by electrodialysis

A preparation process, electrodialysis technology, applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problems of high energy consumption, cumbersome process, secondary pollution, etc., achieve low energy consumption, simple process, The effect of easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

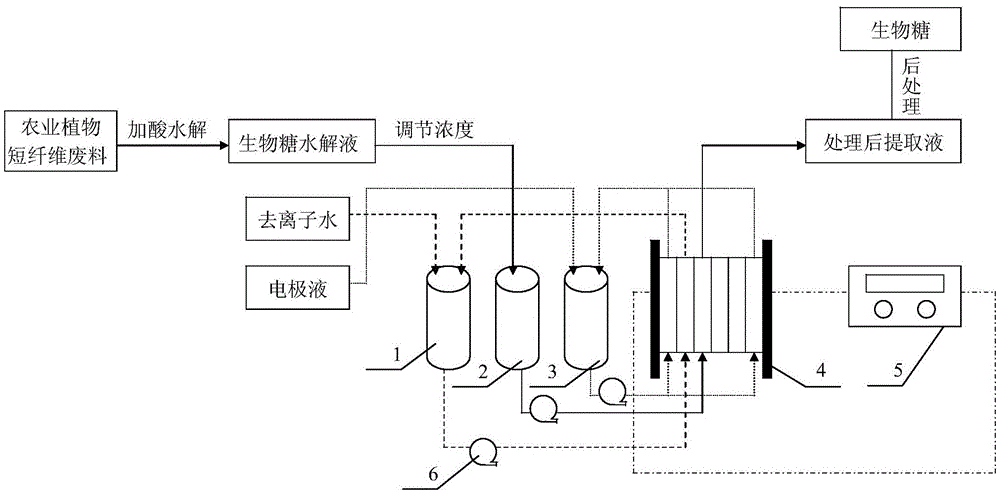

[0026] like figure 1 As shown, the present embodiment removes the residual acid in the biological sugar hydrolyzate according to the following steps:

[0027] Agricultural plant short fiber waste (corn cob) is hydrolyzed with the pentosan in the plant fiber under the action of 8% sulfuric acid, obtains 500ml of biological sugar hydrolyzate (mainly containing xylose and a small amount of sulfuric acid and colloid, albumen, pigment, its pH The value is about 1.0, the conductivity is about 13.5mS / cm, the sugar content is 6.5%, and the sulfuric acid content is 0.76%);

[0028] Set up the electrodialysis unit, such as figure 1 As shown, the electrodialysis device is composed of desalination chamber material tank 2, concentration chamber material tank 1, electrode chamber material tank 3, membrane module 4, three circulating pumps 6, DC power supply 5 and pipelines; the membrane module is composed of anode, cathode and It consists of cation exchange membranes, separators and anion...

Embodiment 2

[0034] This embodiment is the same as Embodiment 1, the only difference is that when electrodialysis is carried out, the operating current density is controlled at 20mA / cm 2 .

[0035] The operation time of the whole process of this embodiment is 75 minutes, the removal rate of residual acid is 99.2%, and the recovery rate of biological sugar is 83.2%.

Embodiment 3

[0037] This embodiment is the same as Embodiment 1, the only difference is that when electrodialysis is carried out, the operating current density is controlled at 30mA / cm 2 .

[0038] The operating time of the whole process of this embodiment is 73 minutes, the removal rate of residual acid is 99.3%, and the recovery rate of biological sugar is 81.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com