Cationic silicon-containing acrylate fabric water repellent and preparation method thereof

A silicon acrylate and cationic technology, which is applied in textiles and papermaking, improved hand feeling fibers, fiber treatment, etc., can solve the problems of unstable emulsion reaction, high viscosity of macromolecular silicone oil, difficult emulsification and dispersion, etc., to improve water repellency effect, excellent film-forming performance, low adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In this example, a cationic silicon-containing acrylate fabric water repellent is prepared from the following raw materials by weight: 900 parts of acrylate mixed monomers, 100 parts of silicone monomers, 30 parts of emulsifier, and 3 parts of initiator. parts, 30 parts of crosslinking agent, 4000 parts of deionized water;

[0051] The acrylate mixed monomers are methyl methacrylate (MMA), butyl acrylate (BA) and acrylic acid (AA) in a mass ratio of 5.0:5.0:0.15;

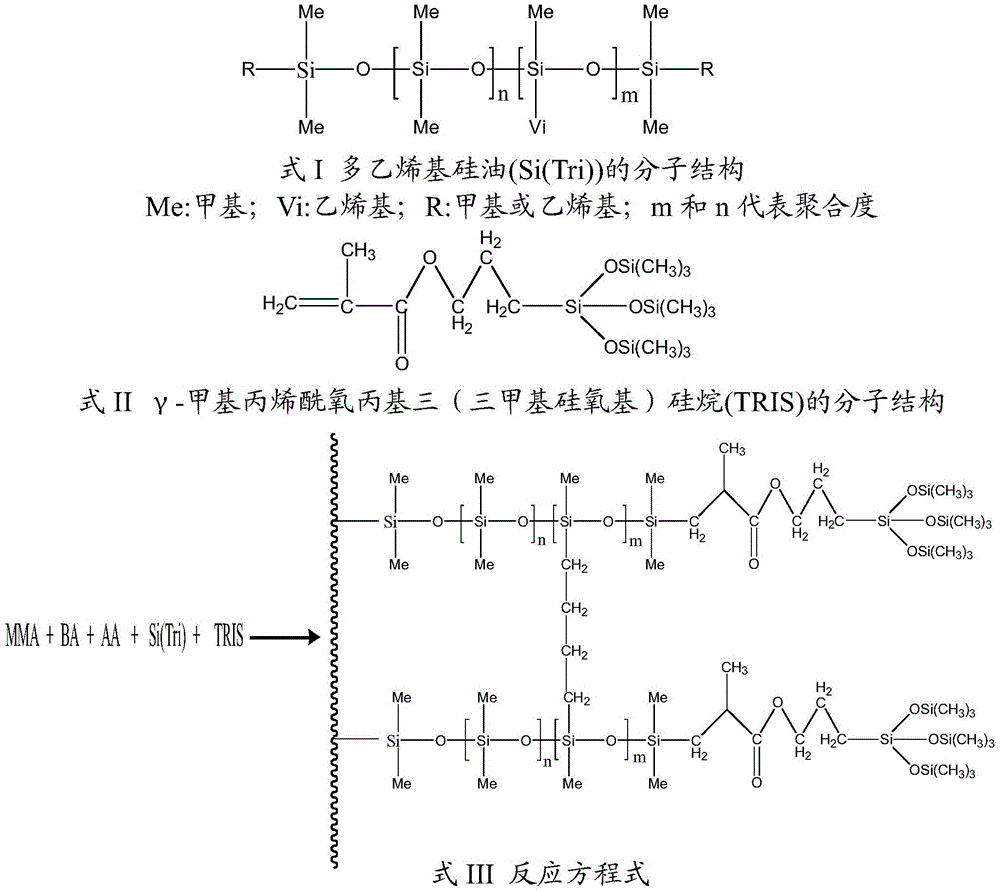

[0052] The organosilicon monomers are γ-methacryloyloxypropyl tris(trimethylsiloxy) silane (TRIS) and polyvinyl silicone oil (Si(Tri), viscosity 3000±500cst, vinyl content 10.0mol %), the mass ratio is 8.5:1.5;

[0053] The emulsifier is composed of octadecyl polyether acrylate trimethyl ammonium chloride (OATAC) and isotridecanol polyoxyethylene ether (DNS500), and the mass ratio of the two is 1.2:0.3;

[0054] Described initiator is azobisisobutylamidine hydrochloride (AIBA);

[0055] The crosslinking ag...

Embodiment 2

[0067] In this embodiment, a cationic silicon-containing acrylate fabric water repellent is prepared from the following raw materials by weight: 800 parts of acrylate mixed monomers, 200 parts of silicone monomers, 40 parts of emulsifier, and 4 parts of initiator. parts, 23 parts of crosslinking agent, 3000 parts of deionized water;

[0068] The acrylate mixed monomers are methyl methacrylate (MMA), butyl acrylate (BA) and acrylic acid (AA) in a mass ratio of 6.5:3.5:0.25;

[0069] The organosilicon monomers are γ-methacryloyloxypropyl tris(trimethylsiloxy) silane (TRIS) and polyvinyl silicone oil (Si(Tri), viscosity 3000±500cst, vinyl content 10.0mol %), the mass ratio is 7.5:2.5;

[0070] The emulsifier is composed of octadecyl polyether acrylate trimethyl ammonium chloride (OATAC) and isotridecanol polyoxyethylene ether (DNS500), and the mass ratio of the two is 1.0:0.4;

[0071] Described initiator is azobisisobutylimidazoline hydrochloride (AIBI);

[0072] The crosslin...

Embodiment 3

[0084]In this example, a cationic silicon-containing acrylate fabric water repellent is prepared from the following raw materials by weight: 720 parts of acrylate mixed monomers, 280 parts of silicone monomers, 48.88 parts of emulsifier, and 4.5 parts of initiator. parts, 18 parts of crosslinking agent, 2800 parts of deionized water;

[0085] The acrylate mixed monomers are methyl methacrylate (MMA), butyl acrylate (BA) and acrylic acid (AA) in a mass ratio of 7.5:2.5:0.30;

[0086] The organosilicon monomers are γ-methacryloyloxypropyl tris(trimethylsiloxy) silane (TRIS) and polyvinyl silicone oil (Si(Tri), viscosity 85000±6000cst, vinyl content 6.0mol %), the mass ratio is 6.5:3.5;

[0087] The emulsifier is composed of octadecyl polyether acrylate trimethyl ammonium chloride (OATAC) and isotridecanol polyoxyethylene ether (DNS500), and the mass ratio of the two is 0.8:0.4;

[0088] Described initiator is azobisisobutylamidine hydrochloride (AIBA);

[0089] The crosslinki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com