Organic-inorganic hybrid material, and preparation method thereof

A hybrid material and inorganic technology, applied in the field of organic-inorganic hybrid materials and their preparation, can solve the problems of easy falling off of carbon nanotubes, high energy consumption, and low catalytic effect, and achieve stable physical and chemical properties, low energy consumption, Conducive to the effect of large-scale promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

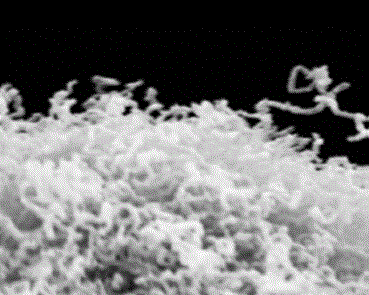

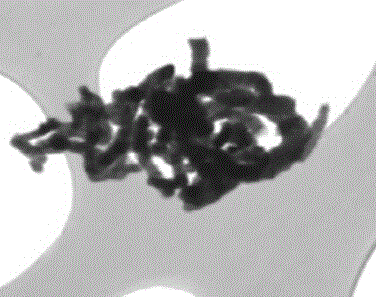

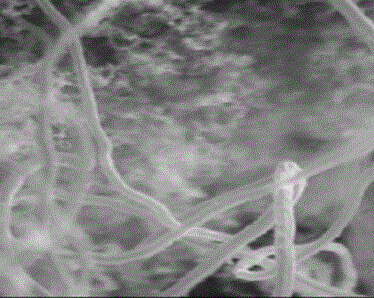

Embodiment 1

[0027] Weigh 1 mL of natural mordenite and 5 mL of an aqueous solution of ferric nitrate with a mass concentration of 0.1%, and stir them evenly. Subsequently, 0.5 mL of sodium hydroxide aqueous solution with a concentration of 2.96 wt% was added and stirred uniformly. The resulting mixture was filtered and dried for 20 hours at a temperature of 110°C; the dried sample was roasted at 450°C for 4.5 hours. Put the treated natural mordenite into a chemical vapor deposition furnace, purge the furnace tube with inert gas for 20 minutes, and then pass hydrogen into the furnace tube. The hydrogen flow rate is 25mL / min. The temperature is raised from room temperature to 500°C at a rate of 7.5 ℃ / min; At this time, a mixture of ethylene and hydrogen gas with a volume ratio of 1:1 is introduced, the reaction temperature is increased to 750℃, the heating rate is 1℃ / min, and the temperature is kept at 750℃ for 2h to obtain carbon nanotubes-natural mercerizing Zeolite hybrid material A.

Embodiment 2

[0029] In Example 1, the concentration of the sodium hydroxide aqueous solution was reduced to 0.74 wt%, and the other operation methods and material composition were unchanged, and the carbon nanotube-natural mordenite hybrid material B was obtained.

Embodiment 3

[0031] In Example 1, the concentration of the sodium hydroxide aqueous solution was increased to 14.8% by weight, and the other operation methods and material composition were unchanged, and the carbon nanotube-natural mordenite hybrid material C was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com