Super-hydrophobic coating capable of being used underwater and preparation and application method thereof

A technology of super-hydrophobic coatings and water materials, which is applied in the direction of chloroprene homopolymer coatings, coatings, and devices for coating liquids on the surface, which can solve the problems of coating peeling, vulnerability to damage, and insufficient service strength. , to achieve the effects of reducing adhesion, reducing contact area, and resisting water/steam penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Prepare the bottom material of the present invention according to the following formula and ratio:

[0050] Silicone Rubber

3g

SBR

2g

C5 (softening point 80°C)

5g

Polyether modified polymethylsiloxane

1g

89g

[0051] Prepare the hydrophobic material according to the following formula and ratio:

[0052] Octadecyltrimethoxysilane

2g

95.9g

Nano silicon oxide (25nm)

2g

0.1g

[0053] Preparation:

[0054] Step 1: Mix the above primers and stir at 30°C for 12 hours to prepare a primer coating solution;

[0055] Step 2: Add 2g of octadecyltrimethoxysilane in the above hydrophobic material to 95.9g of ethanol, stir at room temperature for 2h, then add 2g of nano silicon oxide (25nm) and 0.1g of hydrochloric acid, and stir at 70°C for 12h . Cool to room temperature to prepare a hydrophobic material coating solution.

[0056...

Embodiment 2

[0061] Prepare the bottom material of the present invention according to the following formula and ratio:

[0062]

[0063]

[0064] Prepare the hydrophobic material according to the following formula and ratio:

[0065] Tridecafluorooctyltrimethoxysilane

15g

78.5g

Nano silicon oxide (15nm)

3g

Nano silicon oxide (60nm)

2g

Nano silicon oxide (200nm)

1g

0.5g

[0066] Preparation:

[0067] Step 1: Mix the above primers and stir at 20°C for 24 hours to prepare a primer coating solution;

[0068] Step 2: Add 15g of tridecafluorooctyltrimethoxysilane in the above hydrophobic material to 78.5g of acetone, stir at room temperature for 1h, then add 3g of nano-silica (15nm), 2g of nano-silica (60nm), 1g of nano Silicon oxide (200nm) and 0.5g acetic acid were stirred at 50°C for 24h. Cool to room temperature to prepare a hydrophobic material coating solution.

[0069] Instructions:

...

Embodiment 3

[0074] Prepare the bottom material of the present invention according to the following formula and ratio:

[0075]

[0076]

[0077] Prepare the hydrophobic material according to the following formula and ratio:

[0078] Octadecyltrichlorosilane

0.5g

98.9g

Nano silicon oxide (15nm)

0.5g

0.1g

[0079] Preparation:

[0080] Step 1: Mix the above primers and stir at 50°C for 12 hours to prepare a primer coating solution;

[0081] Step 2: Dissolve octadecyltrichlorosilane in 98.9 g of toluene in the hydrophobic material above, and stir for 0.5 h. Subsequently, 0.5 g of nano silicon oxide (15 nm) and 0.1 g of sulfuric acid were added, and the reaction was stirred at 110° C. for 0.5 h. After cooling to room temperature, a hydrophobic material coating solution was obtained.

[0082] Instructions:

[0083] Step 1: Spray the coating solution of the above-mentioned primer on the glass substrate, and le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

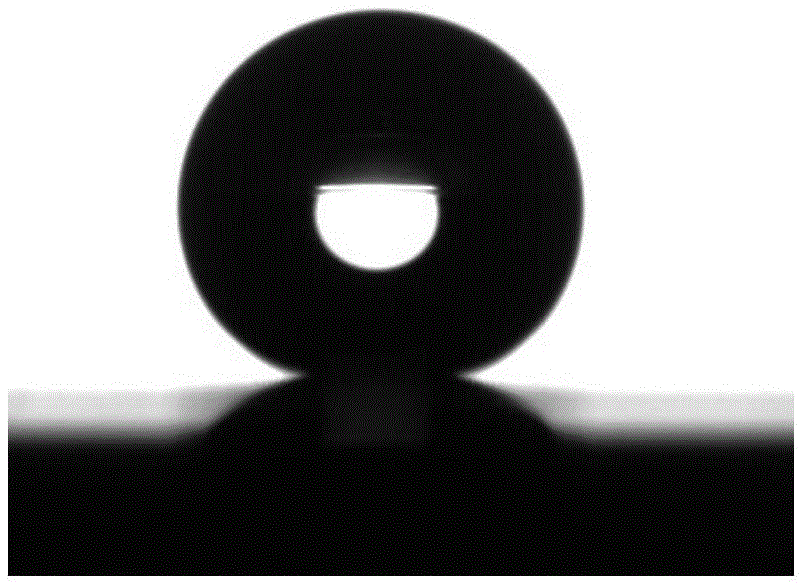

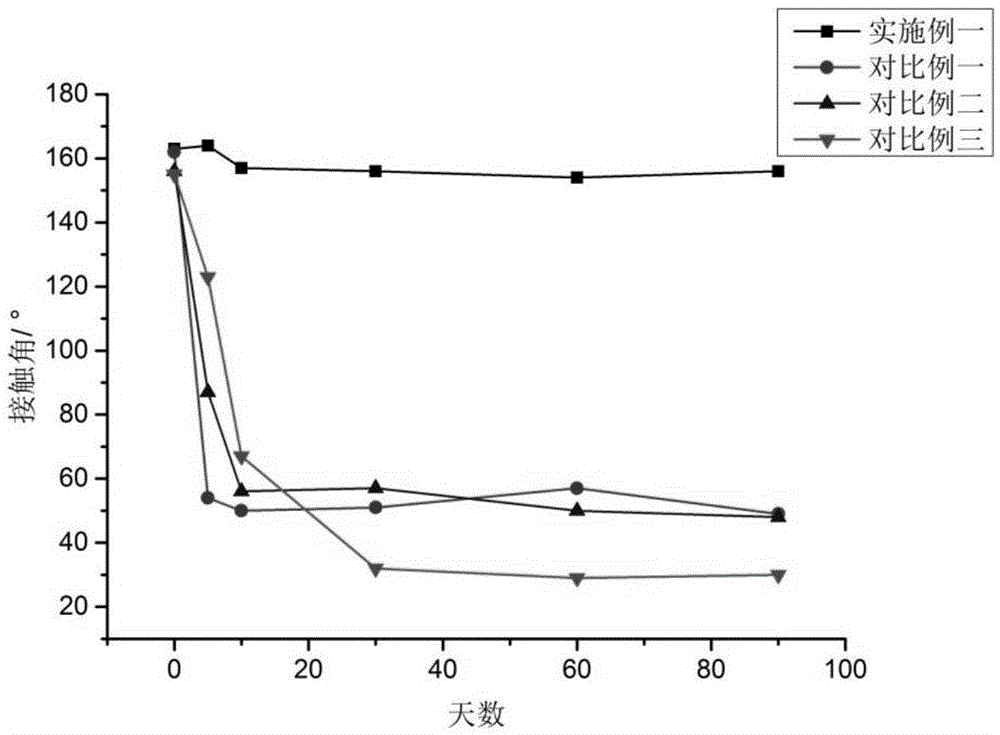

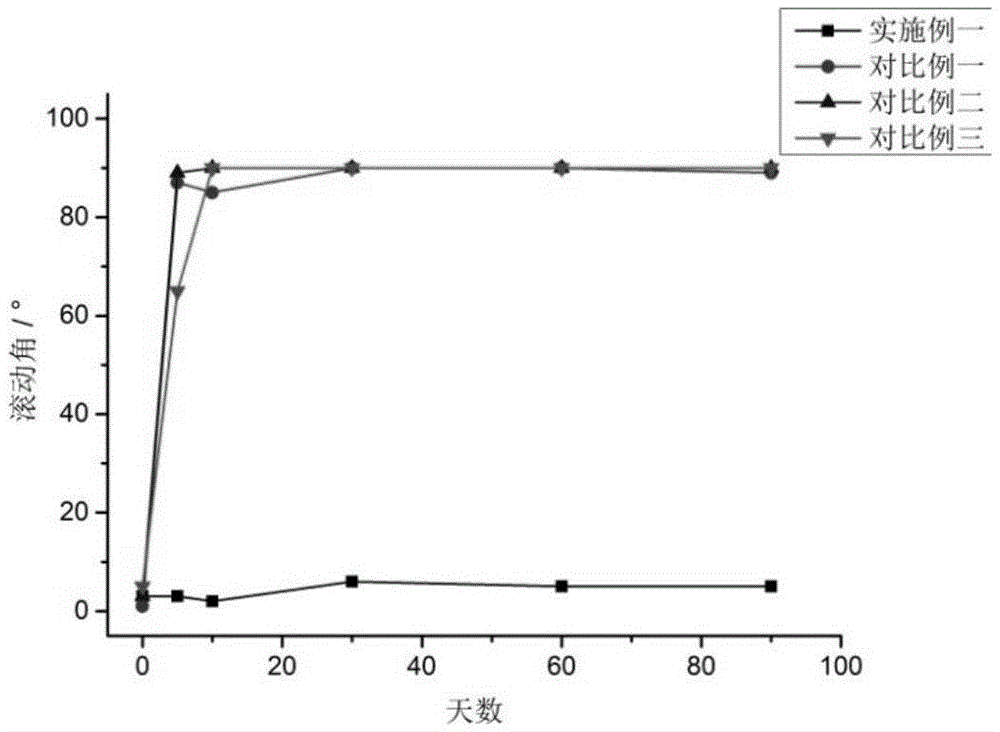

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com