Preparing method for metal/oxide compound surface enhanced Raman active substrate

A composite surface, Raman-active technology, applied in Raman scattering, metal material coating process, superimposed layer plating, etc., can solve harsh synthesis conditions, difficult to prepare multi-layer composite structures, low Raman scattering effect, etc. problem, to achieve the effect of enhanced Raman activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

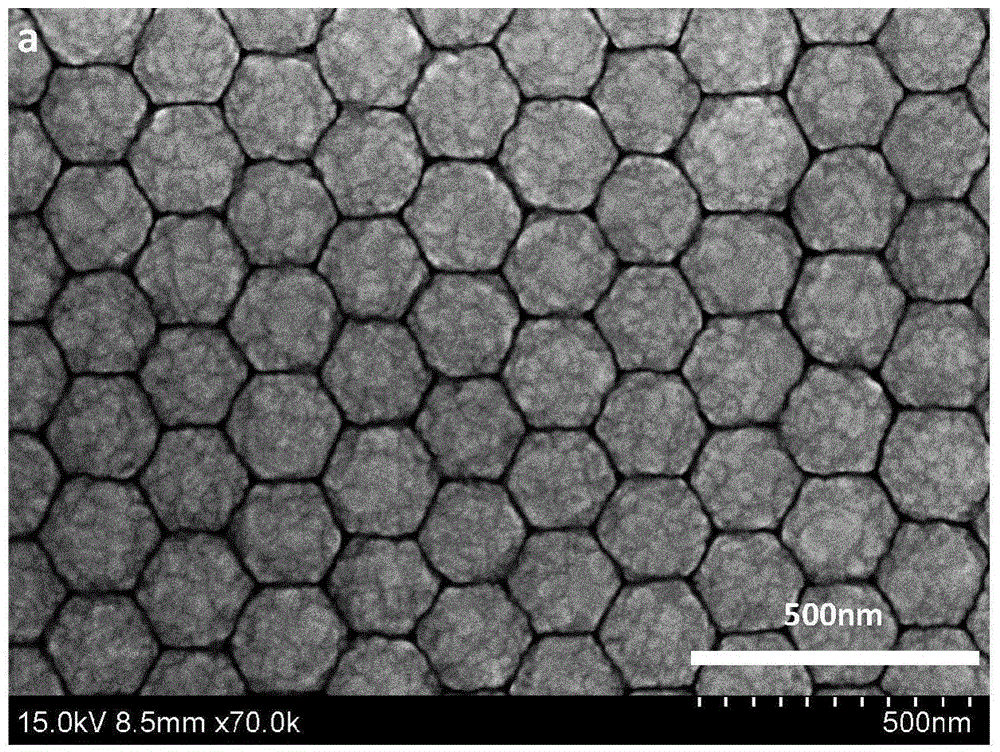

[0036] 1. Prepare a two-dimensional ordered polystyrene colloidal array by self-assembly technology, and the size of the colloidal particles is 200nm.

[0037] 2. Etching is carried out for 30 seconds by plasma etching technology, and the gas used is 20% by volume of oxygen and 80% by volume of argon.

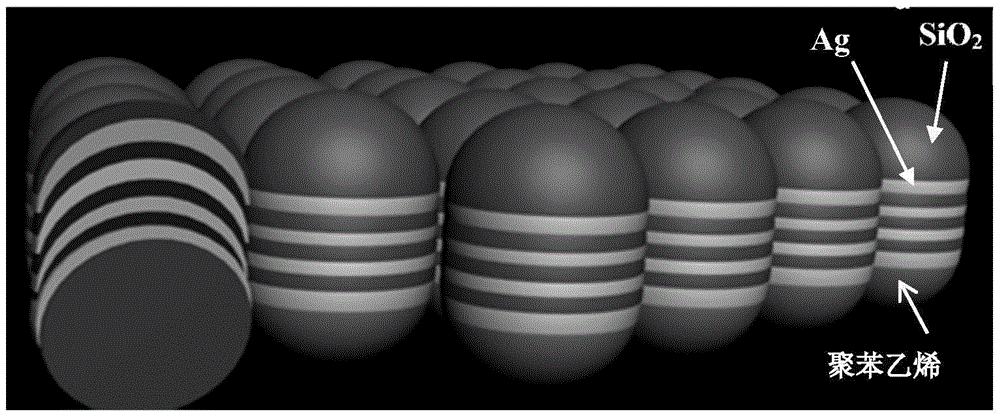

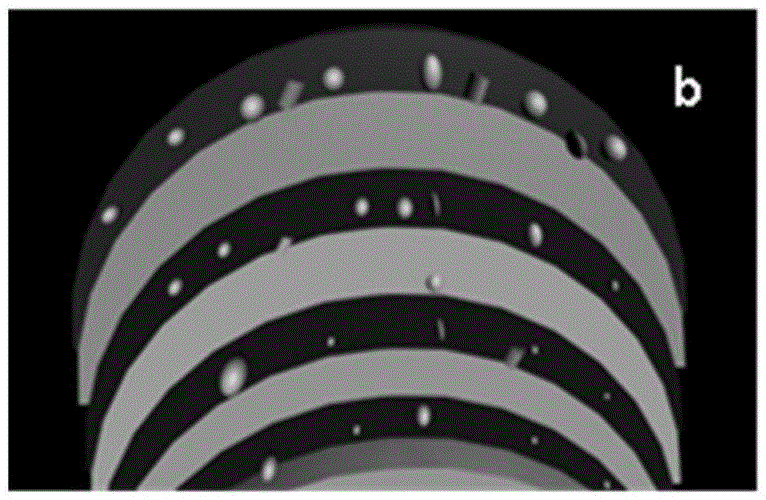

[0038] 3. By sputtering Ag and SiO 2 The composite nano-pattern structure slit array substrate was prepared from the target material, the metal film was prepared by DC sputtering, and the oxide film was prepared by AC sputtering; the substrate was rotated during co-sputtering and the background pressure of the vacuum chamber was 2.4×10 -4 Pa. Ag target and SiO 2 The sputtering power of the targets was 20 watts and 72 watts, respectively. During film deposition, the working pressure is 0.6Pa and Ag and SiO 2 The sputtering rates are 0.06 nanometers per second and 0.01 nanometers per second, and the obtained products are as Figure 1a shown.

[0039] 4. Heat treatment under ...

Embodiment 2

[0045] When the two-dimensional ordered polystyrene colloidal array is prepared by self-assembly technology, the colloidal particle size can be selected in the range of 100-500nm; the distance between the colloidal particles is 10-30nm by etching and can be used as a magnetron sputtering substrate. The conditions and parameters used in the magnetron sputtering step in embodiment 1 are conditions and parameters commonly used in the art, so this condition parameter is only as a preferred solution for implementing the present invention, except for the conditions used in embodiment 1 In addition, those skilled in the art can also achieve the same effect when ensuring that the conditions used are protective atmosphere conditions or vacuum conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com