Cellulose fiber containing aloe extract and preparation method thereof

A technology of aloe vera extract and cellulose fiber, applied in the direction of single-component cellulose rayon, fiber chemical characteristics, textiles and papermaking, etc., can solve the problem of dry breaking strength, wet breaking strength, dry breaking elongation and ultra-long fiber The coefficient of variation of breaking strength in the dry state cannot take into account the mechanical performance indicators at the same time, and it does not have the problems of anti-skin irritation, anti-allergy, and short sustained-release period of plant extracts, so as to achieve good anti-ultraviolet performance, reduce skin itching, and reduce skin moisture loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

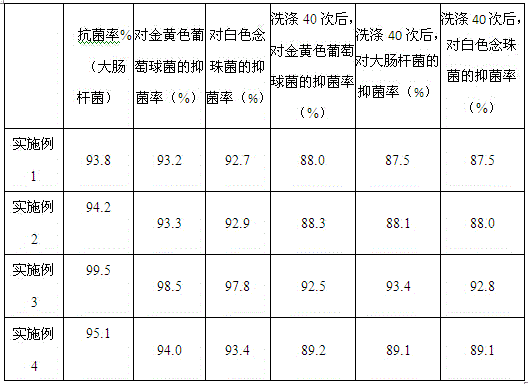

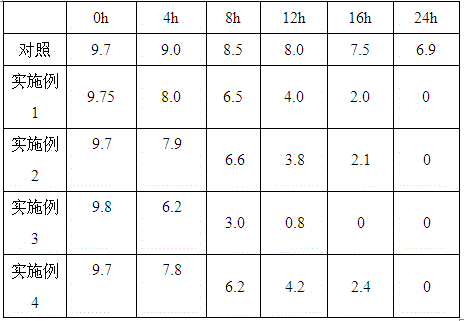

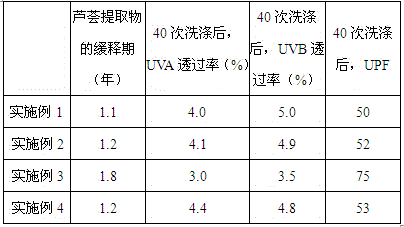

Examples

Embodiment 1

[0038] Embodiment 1 specification is the preparation method of the cellulose fiber containing aloe extract of 1.11dtex*32mm

[0039] Step 1, selection of aloe extract raw material

[0040] The aloe extract has a brown powder appearance, and the aloe vera content is 10%; the particle size is 100% through 80 mesh, and the drying weight is ≦5.0%; the ash content is ≦2.0%; the heavy metal content is ≦10ppm; the total number of colonies is ≦100cfu / g , no Escherichia coli was detected.

[0041] Step 2, the preparation of aloe extract microcapsules

[0042] (1) Preparation of organic phase

[0043] Cyclohexane and chloroform were mixed at a volume ratio of 2:1 as the organic phase.

[0044] (2) Prepare the water phase

[0045] Add the aloe extract to deionized water to prepare an aloe extract solution with a mass content of 70%; add 3 g of ethylenediamine to 10 ml of deionized water, add 5 ml of the above 70% aloe extract solution, and adjust the pH to 7.7. for the water phase. ...

Embodiment 2

[0073] Embodiment 2 specification is the preparation method of the cellulose fiber containing aloe extract of 1.33dtex*38mm

[0074] Step 1, selection of aloe extract raw material

[0075] The aloe extract has a brown powder appearance, and the aloe vera content is 10%; the particle size is 100% through 80 mesh, and the drying weight is ≦5.0%; the ash content is ≦2.0%; the heavy metal content is ≦10ppm; the total number of colonies is ≦100cfu / g , no Escherichia coli was detected.

[0076] Step 2, the preparation of aloe extract microcapsules

[0077] (1) Preparation of organic phase

[0078] Cyclohexane and chloroform were mixed at a volume ratio of 3:1 as the organic phase.

[0079] (2) Prepare the water phase

[0080] Add the aloe extract to deionized water to prepare an aloe extract solution with a mass content of 72%; add 3 g of ethylenediamine to 10 ml of deionized water, add 6 ml of the 72% aloe extract solution, and adjust the pH to 7.7. for the water phase.

[00...

Embodiment 3

[0108] Embodiment 3 specification is the preparation method of the cellulose fiber containing aloe extract of 1.67dtex*38mm

[0109] Step 1, selection of aloe extract raw material

[0110] The aloe extract has a brown powder appearance, and the aloe vera content is 10%; the particle size is 100% through 80 mesh, and the drying weight is ≦5.0%; the ash content is ≦2.0%; the heavy metal content is ≦10ppm; the total number of colonies is ≦100cfu / g , no Escherichia coli was detected.

[0111] Step 2, the preparation of aloe extract microcapsules

[0112] (1) Preparation of organic phase

[0113] Cyclohexane and chloroform were mixed at a volume ratio of 3:2 as the organic phase.

[0114] (2) Prepare the water phase

[0115] Add the aloe extract to deionized water to prepare an aloe extract solution with a mass content of 74%; add 4 g of ethylenediamine to 10 ml of deionized water, add 8 ml of the 74% aloe extract solution, and adjust the pH to 7.7. for the water phase.

[0116...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com