Preparation method of three-dimensional ordered titanium dioxide photonic crystal microballoons covered by silver nanoparticles

A technology of photonic crystal microspheres and silver nanoparticles, which is applied to the preparation of microspheres, chemical instruments and methods, microcapsule preparations, etc., can solve the problem of complex manufacturing process of photonic crystal fibers, signal reproducibility cannot be guaranteed, photonic crystal thin films, etc. Problems such as falling off, achieving the effect of low preparation cost, short preparation cycle, and highly ordered arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

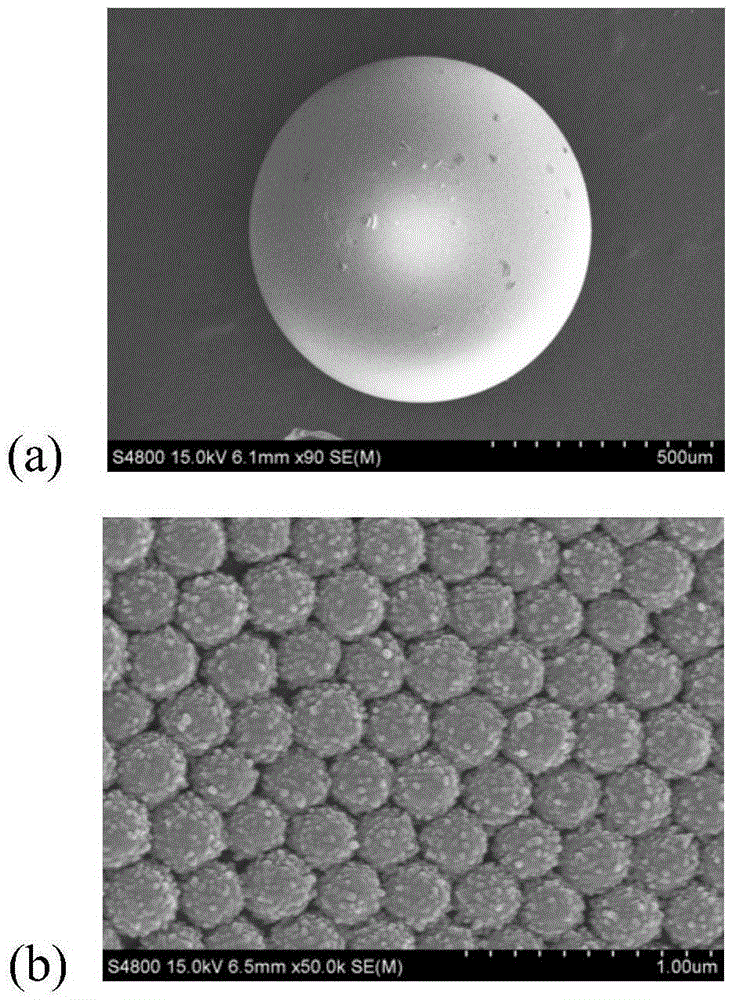

[0018] (1) Preparation of three-dimensional ordered titanium dioxide photonic crystal microspheres: Mix 75mL of absolute ethanol and 50mL of acetonitrile in a three-necked flask, then add 190uL of ammonia and 455uL of water, and quickly add 1.25mL under vigorous stirring Tetrabutyl titanate was vigorously stirred at a constant temperature of 30°C for 6 hours, and after the reaction was completed, it was centrifuged and washed to obtain a titanium dioxide nanoparticle solution. After ultrasonically dispersing the prepared titanium dioxide nanoparticle solution of a certain concentration for half an hour, suck the solution into a 1mL syringe; at the same time, use a 25mL syringe to draw about 25ml of low-viscosity methyl silicone oil; connect the syringe to the interface of the corresponding single-push syringe pump device On, and the injector is driven by a propeller, the flow rate of the colloidal solution is designed to be 0.5ml / h, and the flow rate of the silicone oil is 10ml...

Embodiment 2

[0021] (1) Preparation of three-dimensional ordered titanium dioxide photonic crystal microspheres: Mix 75mL of absolute ethanol and 50mL of acetonitrile in a three-necked flask, then add 190uL of ammonia and 455uL of water, and quickly add 1.25mL under vigorous stirring Tetrabutyl titanate was vigorously stirred at a constant temperature of 30°C for 6 hours, and after the reaction was completed, it was centrifuged and washed to obtain a titanium dioxide nanoparticle solution. After ultrasonically dispersing the prepared titanium dioxide nanoparticle solution of a certain concentration for half an hour, suck the solution into a 1mL syringe; at the same time, use a 25mL syringe to draw about 25ml of low-viscosity methyl silicone oil; connect the syringe to the interface of the corresponding single-push syringe pump device On, and the injector is driven by a propeller, the flow rate of the designed colloid solution is 1ml / h, and the flow rate of the silicone oil is 5ml / h. Drop t...

Embodiment 3

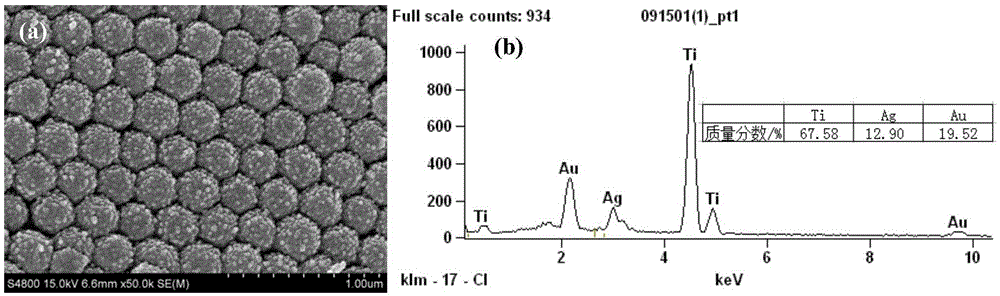

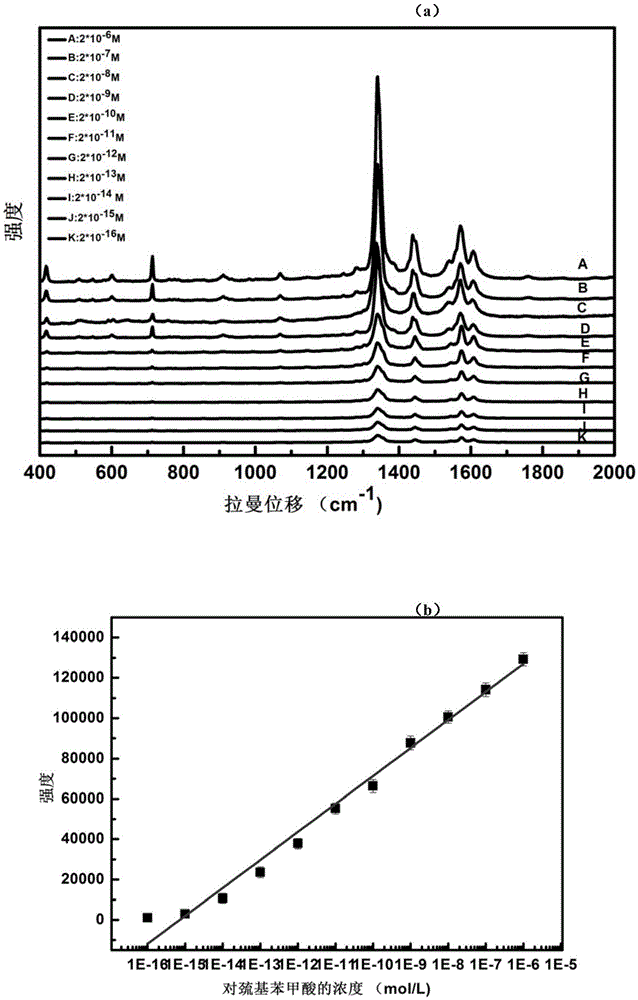

[0024] (1) Preparation of three-dimensional ordered silver nanoparticles coated titanium dioxide photonic crystal microspheres: Mix 75mL of absolute ethanol and 50mL of acetonitrile in a three-necked flask, then add 190uL of ammonia and 455uL of water, under vigorous stirring conditions Quickly add 1.25mL of tetrabutyl titanate, vigorously stir at 30°C for 6 hours, centrifuge and wash after the reaction to obtain a titanium dioxide nanoparticle solution. After ultrasonically dispersing the prepared titanium dioxide nanoparticle solution of a certain concentration for half an hour, suck the solution into a 1mL syringe; at the same time, use a 25mL syringe to draw about 25ml of low-viscosity methyl silicone oil; connect the syringe to the interface of the corresponding single-push syringe pump device On, and the injector is driven by a propeller, the flow rate of the designed colloid solution is 2ml / h, and the flow rate of the silicone oil is 50ml / h. Drop the emulsion into micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com