Dual perovskite/copper-indium-gallium-selenium solar battery

A solar cell, copper indium gallium selenide technology, applied in the field of solar cells, can solve the problems of toxicity, unsuitability for mass production, "selenium loss" and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution will be described in detail below in conjunction with the accompanying drawings and embodiments.

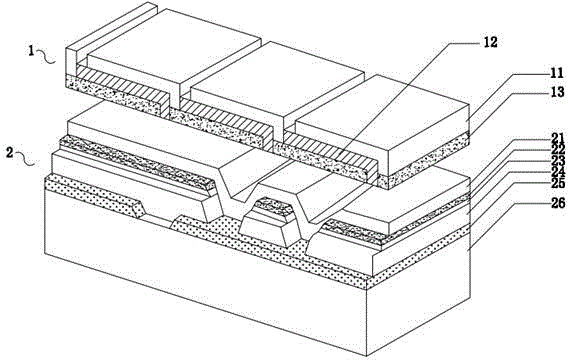

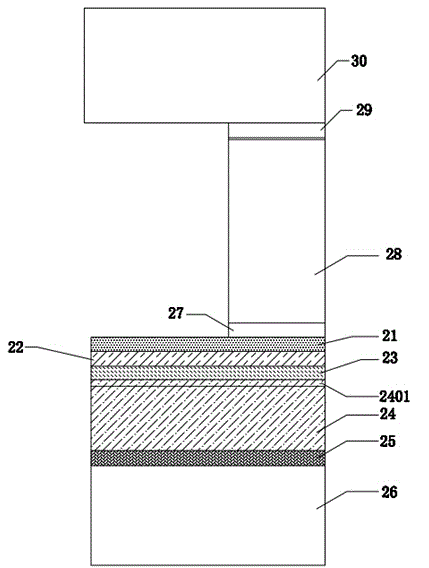

[0020] Please refer to the attached figure 1 , a dual-junction perovskite and copper indium gallium selenide solar cell of the present invention, which comprises: an upper perovskite layer 1, a lower copper indium gallium selenide layer 2, the perovskite layer 1 and copper indium gallium selenide In layer 2, the two node layers are overlapped, and a transparent insulating layer is arranged in the middle. The perovskite layer 1 includes an upper transparent conductive layer 11, a perovskite absorbing layer 12, and a lower transparent conductive layer 13 that are sequentially laminated together; the copper indium gallium selenide layer 2 includes zinc oxide doped layers that are sequentially laminated together. Aluminum conductive layer 21 , zinc oxide layer 22 , cadmium sulfide film layer 23 , copper indium gallium selenium absorption layer 24 , moly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com