A carbon dioxide absorbent, its preparation method and its application method

A carbon dioxide and application method technology, applied in chemical instruments and methods, separation methods, reagents, etc., can solve the problems of slow absorption reaction rate of absorbent, low absorption capacity of absorbent, and decreased absorption capacity, and achieve a simple and feasible preparation method. , the effect of enhancing the applicability of the project and reducing the energy consumption of regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

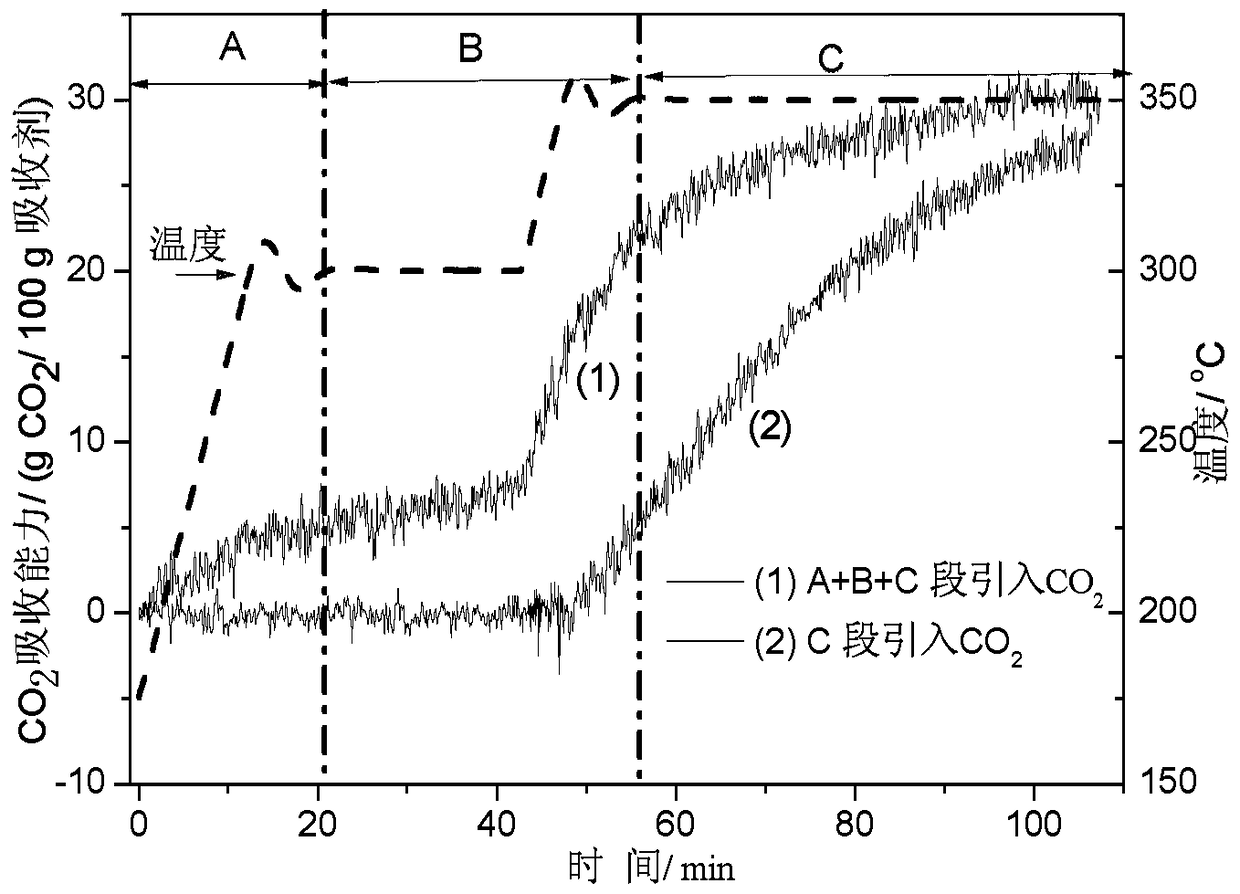

[0043] As shown in the following steps, using NaNO 3 Modified MgCO 3 A magnesium-based carbon dioxide absorbent was prepared, and the absorbent was tested under normal pressure and 100% CO 2 Under the condition of stepwise temperature increase, the CO 2 The case of absorption reactions.

[0044] 1) Take a certain quality of MgCO 3 , and by mass ratio NaNO 3 : MgCO 3 =0.5:1 Weigh a certain mass of NaNO 3 ;

[0045] 2) NaNO 3 After fully dissolving in aqueous solution, MgCO 3 Introducing NaNO 3 Mix thoroughly in the solution;

[0046] 3) Dry the mixed solution to obtain the magnesium-based sample 0.5Na-MgCO 3 , and then the absorbent was calcined and activated at 450°C for 2 hours to obtain NaNO 3 Modified MgO-based CO 2 absorbent.

[0047] For the resulting MgO-based CO 2 Absorbent, the magnesium-based CO 2 The absorption reaction of the absorbent, that is, let the absorbent undergo CO at a low temperature of 300°C 2 of absorption, and then warm up to a higher ...

Embodiment 2

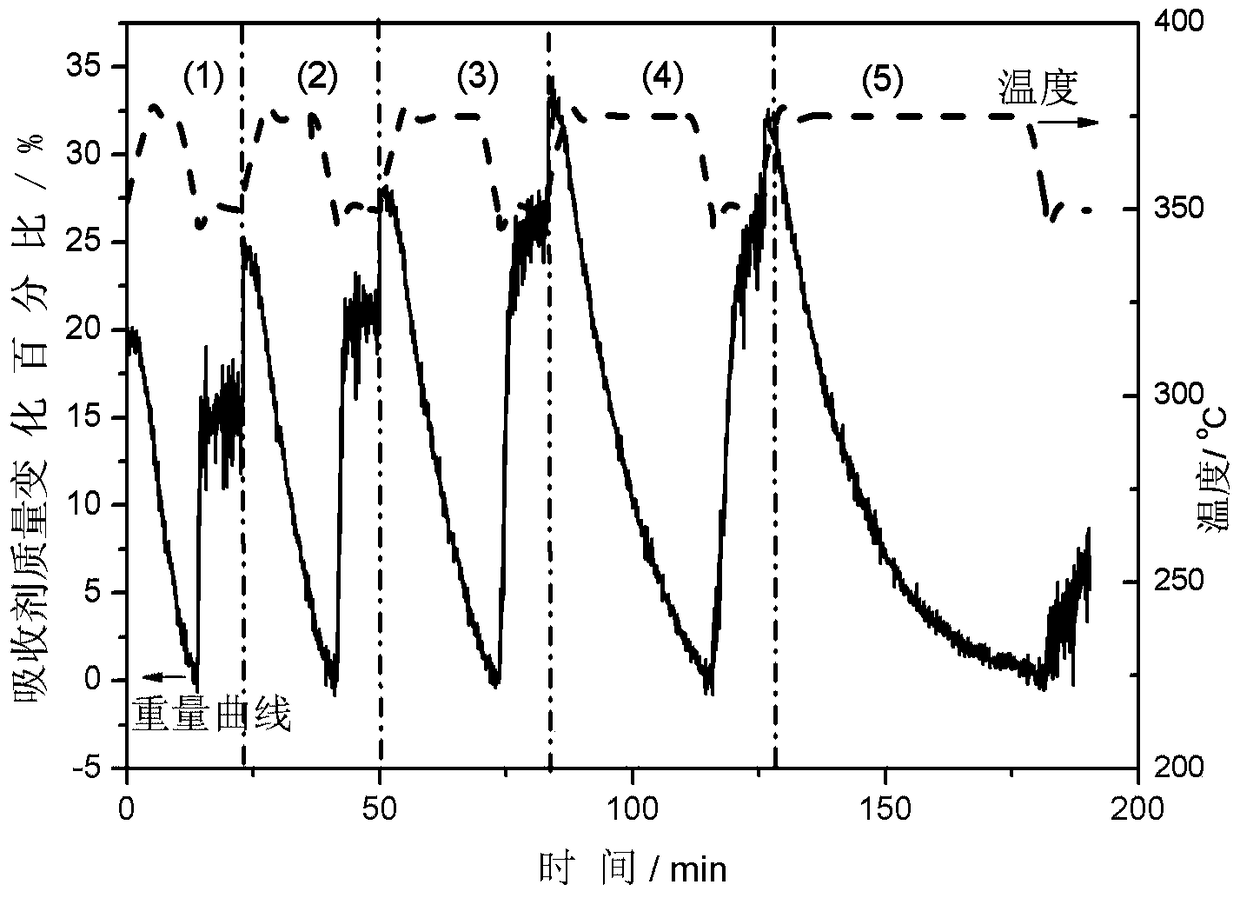

[0049] As shown in the following steps, using NaNO 3 Modified MgCO 3 A magnesium-based carbon dioxide absorbent was prepared, and the absorbent was tested under normal pressure and 100% CO 2 Under the condition that the conversion rate of the magnesium-based carbonate obtained by the carbonation reaction in the regeneration decomposition process is controlled to increase the reaction rate of the absorbent in the next absorption reaction.

[0050] 1) Take a certain quality of MgCO 3 , and by mass ratio NaNO 3 :MgCO 3 =0.5:1 Weigh a certain mass of NaNO 3 ;

[0051] 2) NaNO 3 After fully dissolving in aqueous solution, MgCO 3 Introducing NaNO 3 Mix thoroughly in the solution;

[0052] 3) Dry the mixed solution to obtain the magnesium-based sample 0.5Na-MgCO 3 , and then the absorbent was calcined and activated at 450°C for 2 hours to obtain NaNO 3 Modified MgO-based CO 2 absorbent.

[0053] For the resulting MgO-based CO 2 Absorbent, by controlling the conversion r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com