Porous microneedle array based on metal sintering and manufacturing method thereof

A microneedle array and metal sintering technology, which is applied in the field of biomedical engineering, can solve the problems of a large difference in the strength of the microneedle array and the microneedle, the inability to effectively output a large amount of drugs, and the inability to deliver drugs, etc. High-dose, high-intensity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

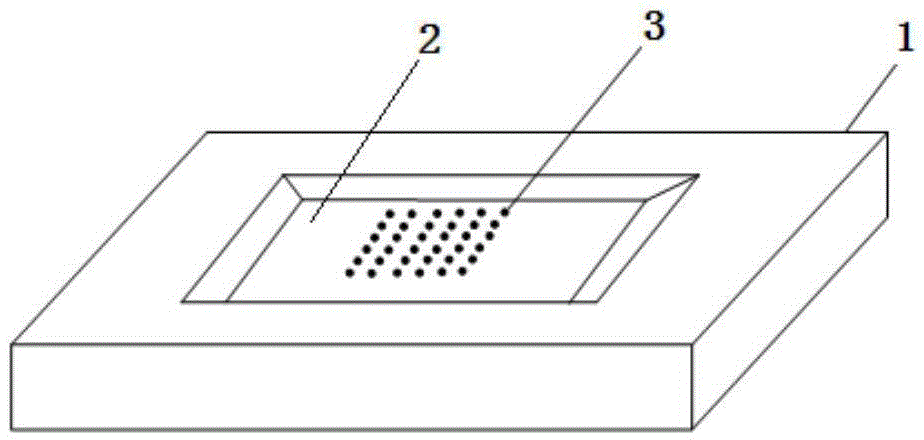

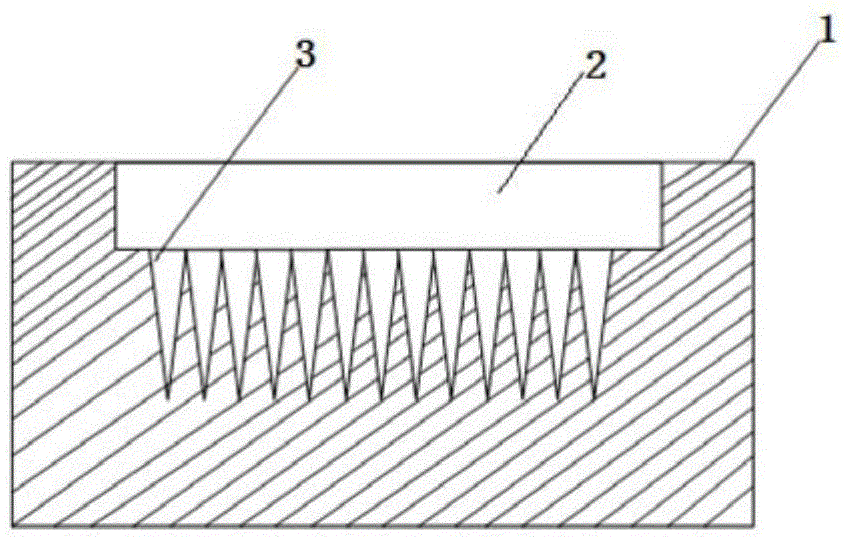

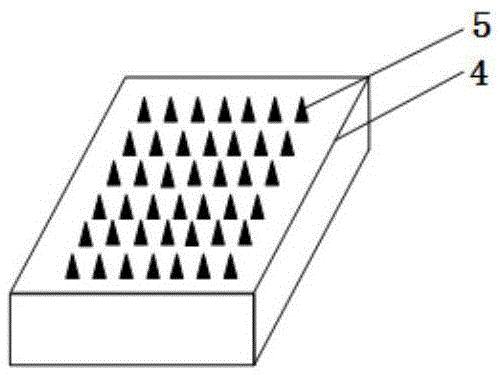

[0043] The manufacturing equipment of the manufacturing method of the metal porous microneedle array made by metal sintering includes a base mold, a ventilated drying oven for evaporating liquid, and a high-temperature sintering furnace for metal sintering, wherein the base mold is such as figure 1 and 2 As shown, a mold body 1 made of polydimethylsiloxane is included, a recess 2 is provided in the mold body, and the hole 3 is provided on the bottom surface of the recess 2 . Specifically, the depth of the concave portion 2 is 2mm, which is to ensure that enough metal titanium powder is filled in the concave portion 2 and the hole 3 after the substrate mixed solution is evaporated to dryness. The holes 3 are arranged in a structure of 6*6, the shape of a single hole 3 is conical, the diameter of the bottom surface is 0.45mm, and the depth is 500um. In this embodiment, the selection of the diameter of the bottom surface is very important, which not only determines and affects t...

Embodiment 2

[0059] The operation method of this embodiment is similar to that of Embodiment 1, the difference is that in this embodiment, a small hole with a diameter of 0.5 mm is selected, and the hole distance is 0.5 mm. The hole distance refers to the shortest distance between the edges of adjacent holes. 49 small holes are evenly distributed on the mold body 1, 7 holes in each row, 7 rows in total. In the present embodiment, the content of metal titanium powder particles (particle diameter 0.2um) in the base mixed solution is 42%, the ethanol content is 48%, the plasticizer is selected dihexyl phthalate, and the content is 1.2%. The agent is polyvinyl alcohol (molecular weight 120,000 to 150,000) and the dosage is 7%, the dispersant is polyethylene glycol (molecular weight 190-210) and the dosage is 1%, and the sintering synergist is selected with kaolin content of 0.8%. The microneedle array obtained after sintering also has similar properties to Example 1.

Embodiment 3

[0061] The operation method of this embodiment is similar to that of Embodiment 1, the difference is that in this embodiment, small holes with a diameter of 0.6mm are selected, and the hole distance is 0.7mm, and 25 small holes are evenly distributed on the mold body 1, and each row 5 total of 5 lines. In the present embodiment, the content of metal titanium powder particles (particle diameter 0.4um) in the base mixed solution is 40%, the ethanol content is 49%, the plasticizer is selected dibutyl phthalate, and the consumption is 2.4%, the bonding The agent is carboxymethyl cellulose with an amount of 6.5%, the dispersant is polyethylene glycol (molecular weight 190-210) with an amount of 1.1%, and the sintering synergist is selected with a kaolin content of 1%. After the sintering process, the cooling rate was adjusted to 5° C. / min, and the performance of the microneedle array prepared according to Example 3 was similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com