Preparation method of manganese-cobalt oxide powder

A technology of manganese oxide cobalt oxide powder and cobalt chloride is applied in chemical instruments and methods, inorganic chemistry, cobalt compounds, etc., to achieve the effect of avoiding agglomeration and precipitation, and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

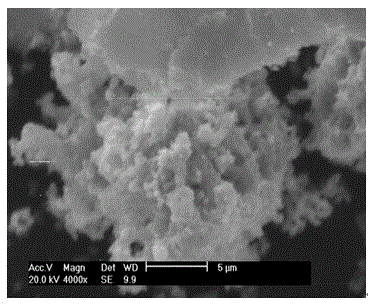

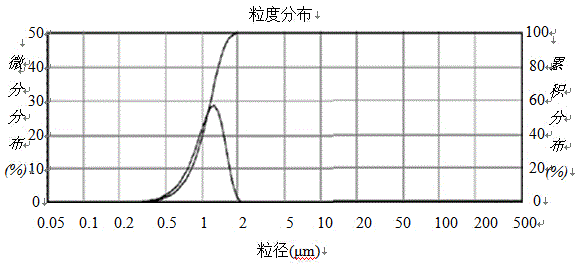

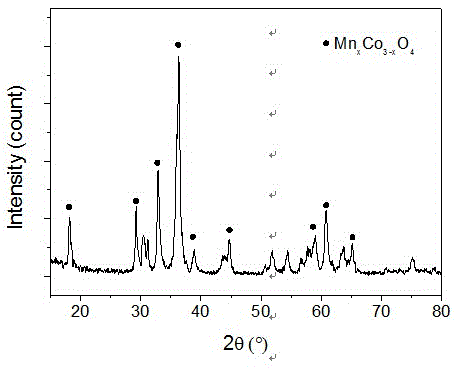

[0022] The preparation method of manganese-cobalt oxide powder described in this embodiment specifically comprises the following steps:

[0023] (1) Weigh 0.2mol of polyvinyl alcohol, 0.1mol of ethylene glycol, and 0.1mol of adipic acid into a beaker;

[0024] (2) Add 100ml of deionized water into the beaker; place it on a magnetic stirrer, set the heating temperature of the magnetic stirrer to 40°C, and stir for 30 minutes to fully dissolve the chelating agent.

[0025] (3) Weigh 5g of cobalt chloride and 2.5g of manganese chloride crystals, put them into the prepared chelating agent solution, and stir with a magnetic stirrer at room temperature for 30 minutes to fully dissolve the cobalt chloride and manganese chloride crystals.

[0026] (4) Place the prepared solution in an incubator, heat it to 70°C for 10 hours, and obtain (MnCo) 3 o 4 Powder precursor solution.

[0027] (5) Pour the precursor solution into the crucible, heat at 110°C for 1 hour, then heat at 5min / °C t...

Embodiment 2

[0029] The preparation method of manganese-cobalt oxide powder described in this embodiment specifically comprises the following steps:

[0030] (1) Weigh 0.8mol of polyvinyl alcohol, 0.4mol of ethylene glycol, and 0.4mol of adipic acid into a beaker;

[0031] (2) Add 100ml of deionized water into the beaker; place it on a magnetic stirrer, set the heating temperature of the magnetic stirrer to 60°C, and stir for 60 minutes to fully dissolve the chelating agent.

[0032] (3) Weigh 2.5g of cobalt chloride and 5g of manganese chloride crystals, put them into the prepared chelating agent solution, and stir with a magnetic stirrer at room temperature for 60 minutes to fully dissolve the cobalt chloride and manganese chloride crystals.

[0033] (4) Place the prepared solution in an incubator, heat it to 80°C for 12 hours, and obtain (MnCo) 3 o 4 Powder precursor solution.

[0034] (5) Pour the precursor solution into the crucible, heat at 120°C for 2 hours, then heat at 10min / °C...

Embodiment 3

[0036] Described in this example (MnCo) 3 o 4 The preparation method of powder specifically comprises the following steps:

[0037] (1) Weigh 0.4mol of polyvinyl alcohol, 0.2mol of ethylene glycol, and 0.2mol of adipic acid into a beaker;

[0038] (2) Add 100ml of deionized water into the beaker; place it on a magnetic stirrer, set the heating temperature of the magnetic stirrer to 50°C, and stir for 60 minutes to fully dissolve the chelating agent.

[0039] (3) Weigh 3.75g of cobalt chloride and 3.75g of manganese chloride crystals, put them into the prepared chelating agent solution, and stir with a magnetic stirrer at room temperature for 60 minutes to fully dissolve the cobalt chloride and manganese chloride crystals.

[0040] (4) Place the prepared solution in an incubator, heat it to 75°C for 11 hours, and obtain (MnCo) 3 o 4 Powder precursor solution.

[0041] (5) Pour the precursor solution into the crucible, heat at 115°C for 1.5 hours, then heat at 8min / °C to 420°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com