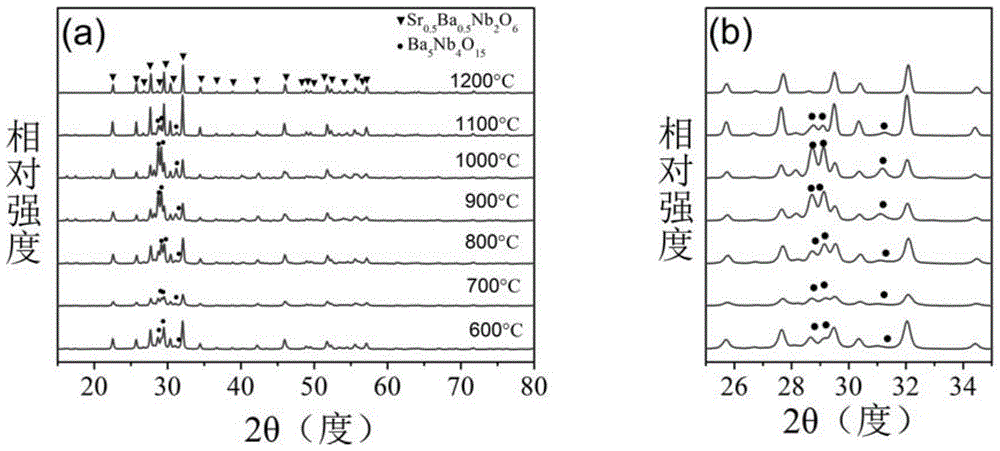

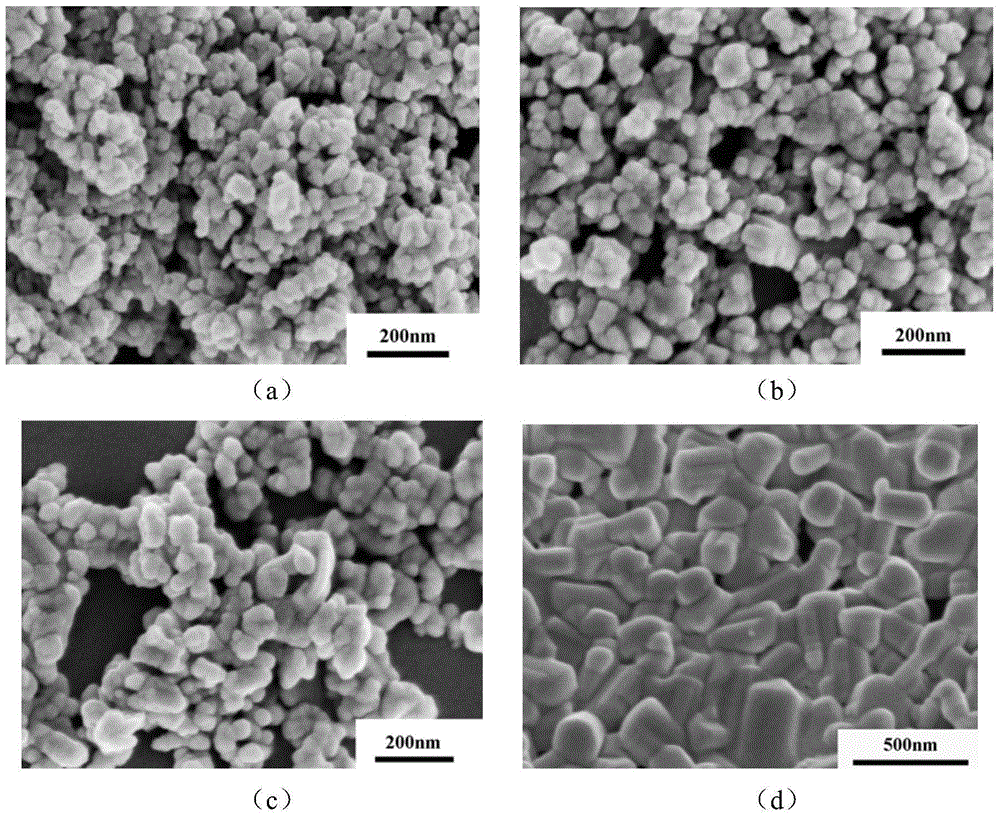

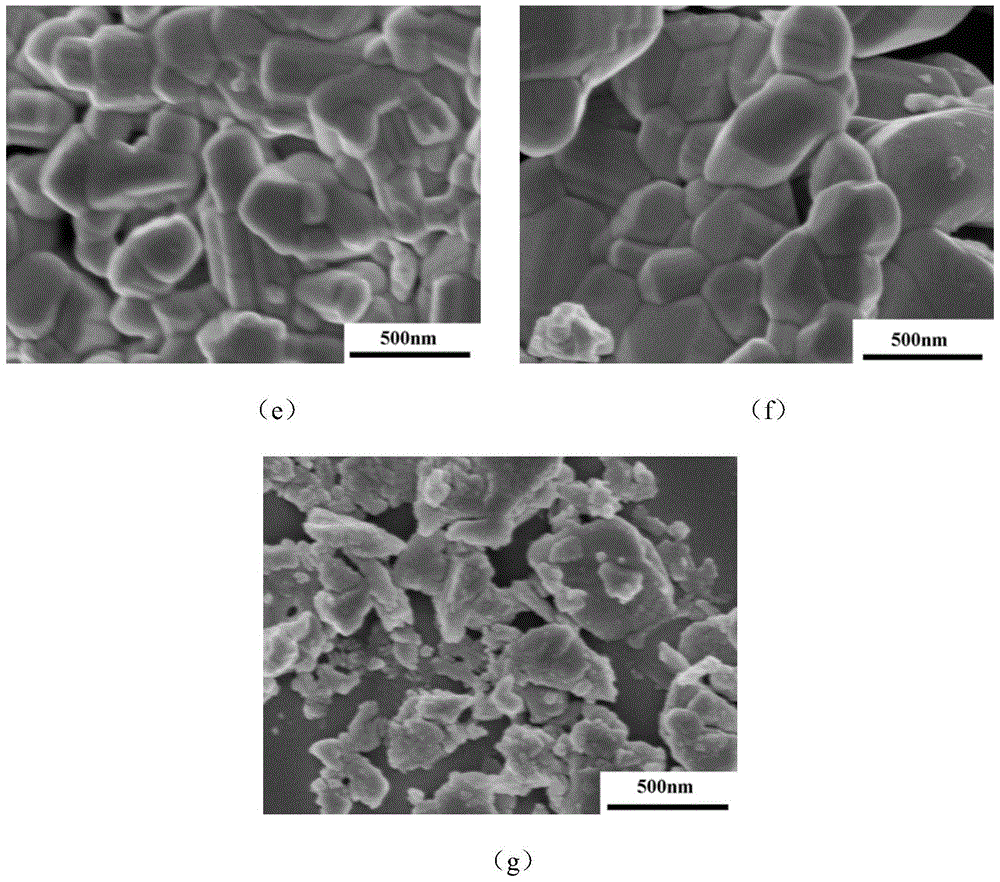

Method for preparing SBN (Sr0.5Ba0.5Nb2O6) nano-powder with improved sol-gel method

A technology of barium strontium niobate and nanopowder, which is applied in the direction of nanotechnology, can solve the problems of potential safety hazards, and achieve the effects of easy completion, stable sol, and avoiding highly toxic reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] To prepare 0.05molSr 0.5 Ba 0.5 Nb 2 o 6 Taking nano powder as an example, the required raw materials are 43.51 grams of niobium oxalate, 3.69 grams of strontium carbonate, 4.93 grams of barium carbonate, 63.36 grams of citric acid, 95.52 grams of ethylene glycol, and 100 ml of ammonia water. The specific operation is as follows:

[0023] 1. Dissolve 43.51 grams of niobium oxalate in 500 ml of deionized water at room temperature, and keep stirring to obtain a clear aqueous solution of niobium oxalate;

[0024] 2. In the prepared niobium oxalate aqueous solution, add 100ml of ammonia water dropwise while stirring to obtain Nb(OH) 5 white precipitate;

[0025] 3. Add Nb(OH) 5 The precipitate was aged in a water bath at 80°C for 12 hours, and after cooling, suction filtration and washing were performed to remove excess ammonia water;

[0026] 4. Dissolve 63.36 grams of citric acid in 100 ml of deionized water to obtain an aqueous solution of citric acid;

[0027] 5...

Embodiment 2

[0033] To prepare 0.04molSr 0.5 Ba 0.5 Nb 2 o 6Taking nano powder as an example, the required raw materials are 34.81 grams of niobium oxalate, 2.95 grams of strontium carbonate, 3.95 grams of barium carbonate, 50.69 grams of citric acid, 76.42 grams of ethylene glycol, and 80 ml of ammonia water. The specific operation is as follows:

[0034] 1. Dissolve 34.81 grams of niobium oxalate in 400 ml of deionized water at room temperature, and keep stirring to obtain a clear niobium oxalate solution;

[0035] 2. In the prepared niobium oxalate aqueous solution, add 80ml of ammonia water dropwise while stirring to obtain Nb(OH) 5 white precipitate;

[0036] 3. Add Nb(OH) 5 The precipitate was aged in a water bath at 80°C for 12 hours, and after cooling, suction filtration and washing were performed to remove excess ammonia water;

[0037] 4. Dissolve 50.69 grams of citric acid in 80 ml of deionized water to obtain an aqueous solution of citric acid;

[0038] 5. Add Nb(OH) 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com