Special oxygen-evolving fertilizer for promoting rice root growth and regreening and reviving and preparation method thereof

A technology for root growth and special fertilizer, applied in the agricultural field, can solve problems such as shortage, and achieve the effect of reducing fertilizer loss, reducing release rate, and promoting root growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

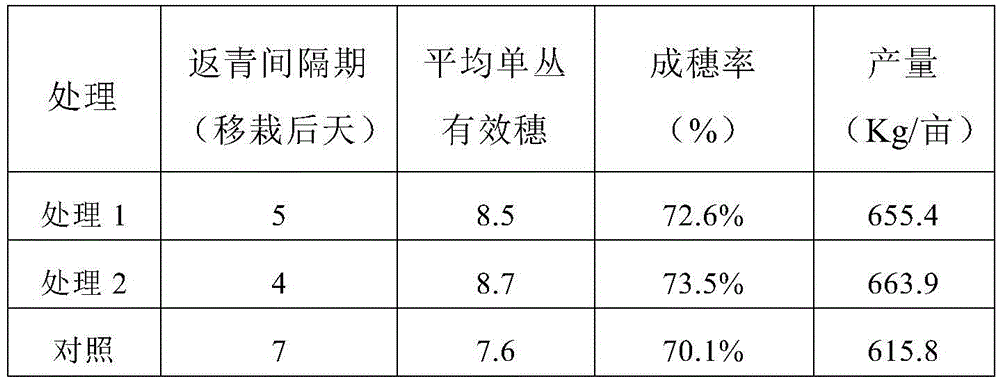

Examples

Embodiment 1

[0023] 45 parts of urea, 20 parts of calcium superphosphate, 15 parts of potassium chloride, 15 parts of magnesium peroxide, 3 parts of attapulgite powder, 0.3 parts of carboxymethyl cellulose, 1.2 parts of bitter kudzu extract, 0.5 parts of Coptis chinensis extract;

[0024] 1) Mix the urea, calcium superphosphate, potassium chloride and magnesium peroxide in the parts by weight and then pulverize them, pass through a 160 mesh sieve, then add the extracts of bitter kudzu and rhizoma coptis in the parts by weight, stir and mix , and then produce compound granular fertilizer with a diameter of 3-4 mm according to the conventional process;

[0025] 2) Put the above compound granule fertilizer into the drum coating machine, preheat at 30-40°C for 10 minutes, the speed of the coating machine is 55 rpm, spray the attapulgite into the drum after preheating Powder and carboxymethyl fiber solution (concentration 2%), after spraying, control the temperature to be 35-40°C, discharge the...

Embodiment 2

[0027] 50 parts of urea, 23 parts of superphosphate, 11 parts of potassium chloride, 10 parts of magnesium peroxide, 3 parts of attapulgite powder, 0.7 parts of carboxymethyl cellulose, 1.3 parts of bitter kudzu extract, 1.0 part of Coptis chinensis extract;

[0028] 1) After mixing the urea, superphosphate, potassium chloride and magnesium peroxide in the parts by weight, pulverize them, pass through a 150 mesh sieve, then add the extracts of bitter kudzu and rhizoma coptis in the parts by weight, stir and mix , and then produce compound granular fertilizer with a diameter of 3-4 mm according to the conventional process;

[0029] 2) Put the above-mentioned compound granular fertilizer into the drum coating machine, preheat at 30-40°C for 8 minutes, and the speed of the coating machine is 55 rpm, spray the attapulgite into the drum after preheating Powder and carboxymethyl fiber solution (concentration 5%), after spraying, the temperature is controlled to be 35-40 ° C, and the...

Embodiment 3

[0031] 45 parts of urea, 20 parts of calcium superphosphate, 17 parts of potassium chloride, 11 parts of magnesium peroxide, 5 parts of attapulgite powder, 0.5 part of carboxymethyl cellulose, 1.0 part of bitter kudzu extract, 0.5 part of Coptis chinensis extract;

[0032] 1) After mixing the urea, superphosphate, potassium chloride and magnesium peroxide in the parts by weight, pulverize them, pass through a 120-mesh sieve, then add the extracts of bitter kudzu and coptis chinensis in the parts by weight, stir and mix , and then produce compound granular fertilizer with a diameter of 3-4 mm according to the conventional process;

[0033] 2) Put the above compound granule fertilizer into the drum coating machine, preheat at 30-40°C for 5 minutes, the coating machine speed is 55 rpm, spray the attapulgite into the drum after preheating powder and carboxymethyl fiber solution (concentration 5%), after spraying, the temperature is controlled to be 35-40° C., discharged after 22 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com