Modified natural rubber bridge support material and preparation method thereof

A technology of natural rubber and bridge bearing, applied in the field of bridge construction engineering, can solve the problems of high shock absorption, poor damping performance, poor physical and mechanical properties, and high raw material cost, achieve outstanding solvent resistance, reduce production cost, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

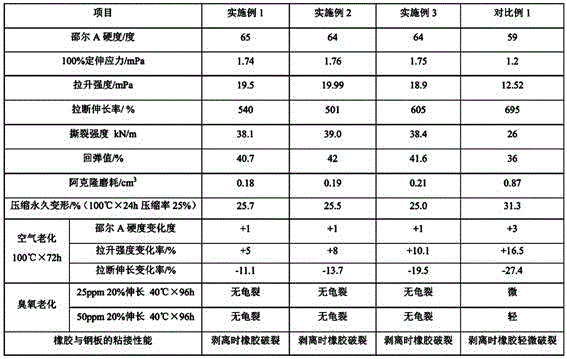

Examples

Embodiment 1

[0016] (1) Weigh CPE-140B40kg, NR-smoke sheet 3#45kg, terpene phenolic resin 1.5kg, rubber release agent TM-800.3kg, light magnesium oxide 4kg, carbon black N55032kg, HFR-300025kg, phthalate Dioctyl formate 3kg, barium stearate 2.5kg, zinc oxide 3kg, stearic acid 0.5kg, paraffin 0.5kg, hindered phenol AO-608kg, dicumyl peroxide 3kg, silane coupling agent KH-5701.8kg, Sulfur 0.5kg;

[0017] (2) Put HFR-3000 and silane coupling agent KH-570 in a mixer, heat to 60°C and stir for 8 minutes, and stack for 1.5 hours after discharging to obtain modified HFR-3000;

[0018] (3) Put CPE-140B on the heating type open mill, set the roller distance to 0.8mm, and carry out plasticization at 80°C for 13 minutes. After plasticization, add modified HFR-3000, light magnesium oxide, and stearic acid in sequence Barium, paraffin, mixed evenly, to get CPE mixing masterbatch;

[0019] (4) Put the natural rubber NR-smoke sheet 3# on the heated and pressurized internal mixer, set the roller distanc...

Embodiment 2

[0022] (1) Weigh CPE-140B50kg, NR-smoke sheet 3#50kg, terpene phenolic resin 1.5kg, rubber release agent TM-800.5kg, light magnesium oxide 5kg, carbon black N55030kg, HFR-300030kg, phthalate Dioctyl formate 5kg, barium stearate 3kg, zinc oxide 3kg, stearic acid 1kg, paraffin 1kg, hindered phenol AO-6010kg, dicumyl peroxide 3.5kg, silane coupling agent KH-5701.8kg, sulfur 0.9 kg;

[0023] (2) Put HFR-3000 and silane coupling agent KH-570 in a mixer, heat to 75°C and stir for 6 minutes, and stack for 2 hours after discharging to obtain modified HFR-3000;

[0024] (3) Put CPE-140B on the heating type open mill, set the roller distance to 1mm, and carry out plasticization at 85°C for 15 minutes. After plasticization, add modified HFR-3000, light magnesium oxide, and barium stearate in sequence , paraffin, mixed evenly to obtain the CPE mixing masterbatch;

[0025] (4) Put the natural rubber NR-smoke sheet 3# on the heating and pressurized internal mixer, set the roller distance ...

Embodiment 3

[0028] (1) Weigh CPE-140B65kg, terpene phenolic resin 4kg, NR-smoke sheet 3#55kg, rubber release agent TM-800.6kg, light magnesium oxide 6kg, carbon black N55032kg, HFR-300035kg, phthalic acid Dioctyl ester 6kg, barium stearate 3.5kg, zinc oxide 4kg, stearic acid 1.5kg, paraffin 1.5kg, hindered phenol AO-6012kg, dicumyl peroxide 5kg, silane coupling agent KH-5701.8kg, sulfur 1.5kg;

[0029] (2) Put HFR-3000 and silane coupling agent KH-570 in a mixer, heat to 85°C and stir for 4 minutes, and stack for 2.5 hours after discharging to obtain modified HFR-3000;

[0030](3) Put CPE-140B on the heating type open mill, set the roller distance to 0.9mm, and carry out plasticization at 90°C for 14 minutes. After plasticization, add modified HFR-3000, light magnesium oxide, and stearic acid in sequence Barium, paraffin, mixed evenly, that is the CPE mixing masterbatch;

[0031] (4) Put the natural rubber NR-smoke sheet 3# on the heating and pressurized internal mixer, set the roller d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com