Method for recycling rare earth and platinum group metal from spent automobile emission purification catalyst

A technology for purifying catalysts and automobile catalysts, applied in the direction of improving process efficiency, etc., to achieve the effect of simple method, high economic benefit and high dissolution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

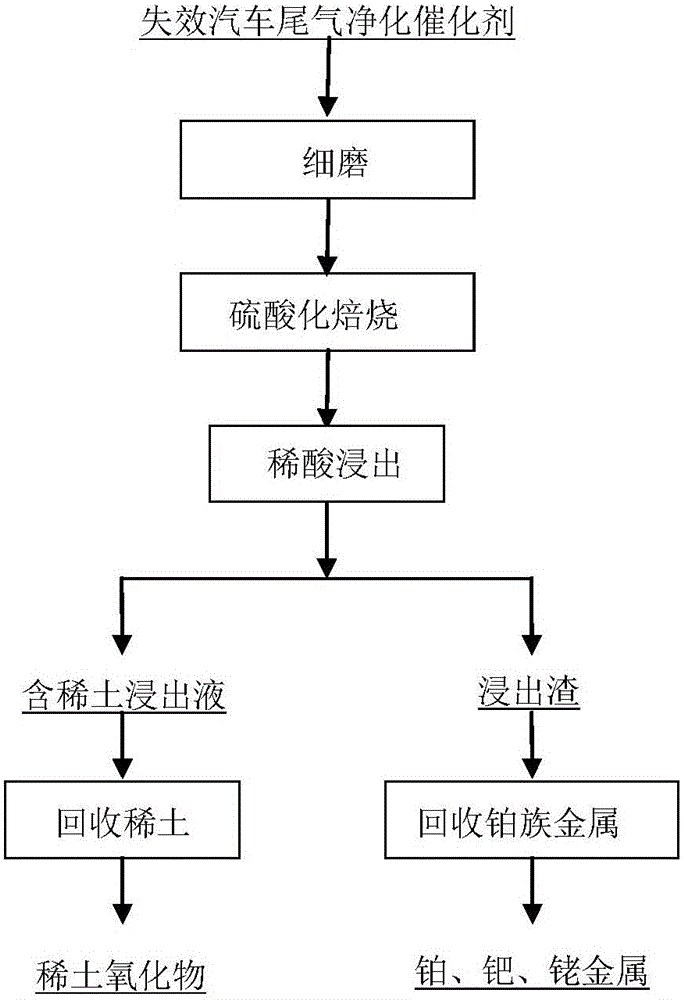

[0016] Embodiment 1, see attached figure 1 1. Finely grind the exhausted automobile exhaust purification catalyst to a particle size range of 74-150 μm, mix the finely ground exhausted automobile exhaust catalyst with concentrated acid sulfuric acid at a mass ratio of 1:1, and roast in a muffle furnace at a temperature of 200° C. for 4 hours; The roasted product is leached with 1mol / L sulfuric acid at 80°C for 3 hours, maintaining a liquid-solid ratio of 3, and after filtration and separation, the rare earth solution and insoluble slag containing platinum group metals are obtained; add sodium sulfate to the rare earth solution and react at 80°C After 3 hours, the precipitation of rare earth sulfate double salt was obtained, separated from other components, and after subsequent treatment, rare earth oxides of lanthanum and cerium were obtained; the insoluble residue was dissolved with hydrochloric acid + chlorine gas, and the platinum group metal solution was processed through t...

Embodiment 2

[0017] Embodiment 2, see attached figure 1 1. Finely grind the exhausted automobile exhaust purification catalyst to a particle size range of 74-90 μm, mix the finely ground exhausted automobile exhaust catalyst with concentrated acid sulfuric acid at a mass ratio of 1:0.8, and keep the temperature in a muffle furnace at 300° C. for 3 hours for roasting; The roasted product is leached with 1mol / L sulfuric acid at 60°C for 4 hours, maintaining a liquid-solid ratio of 3, and after filtration and separation, the rare earth solution and insoluble residue containing platinum group metals are obtained; add sodium sulfate to the rare earth solution and react at 80°C After 3 hours, the precipitation of rare earth sulfate double salt was obtained, separated from other components, and after subsequent treatment, rare earth oxides of lanthanum and cerium were obtained; the insoluble residue was dissolved with hydrochloric acid + chlorine gas, and the platinum group metal solution was proc...

Embodiment 3

[0018] Embodiment 3, see attached figure 1 1. Finely grind the exhausted automobile exhaust purification catalyst to a particle size range of 74-125 μm, mix the finely ground exhausted automobile exhaust catalyst with concentrated acid sulfuric acid at a mass ratio of 1:1.2, and keep the temperature in a muffle furnace at 250° C. for 5 hours of roasting; The roasted product is leached with 0.5mol / L sulfuric acid at 80°C for 4 hours, maintaining a liquid-solid ratio of 4, and after filtration and separation, the rare earth solution and insoluble slag containing platinum group metals are obtained; add sodium sulfate to the rare earth solution, and at 80°C After reacting for 3 hours, the precipitation of rare earth sulfate double salt is obtained, which is separated from other components, and after subsequent treatment, rare earth oxides of lanthanum and cerium are obtained; the insoluble residue is dissolved with hydrochloric acid + chlorine gas, and the platinum group metal solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com