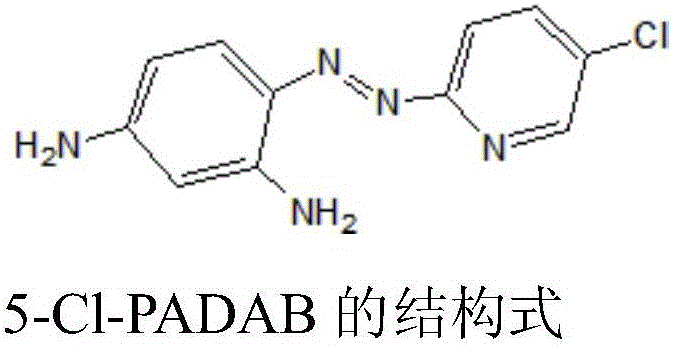

Calcium alginate/5-Cl-PADAB microspheres and preparation method and application thereof

A calcium alginate, 5-cl-padab technology, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., can solve problems such as unseen macromolecular organic matter, and achieve environmental friendliness, cheap and easy-to-obtain raw materials , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

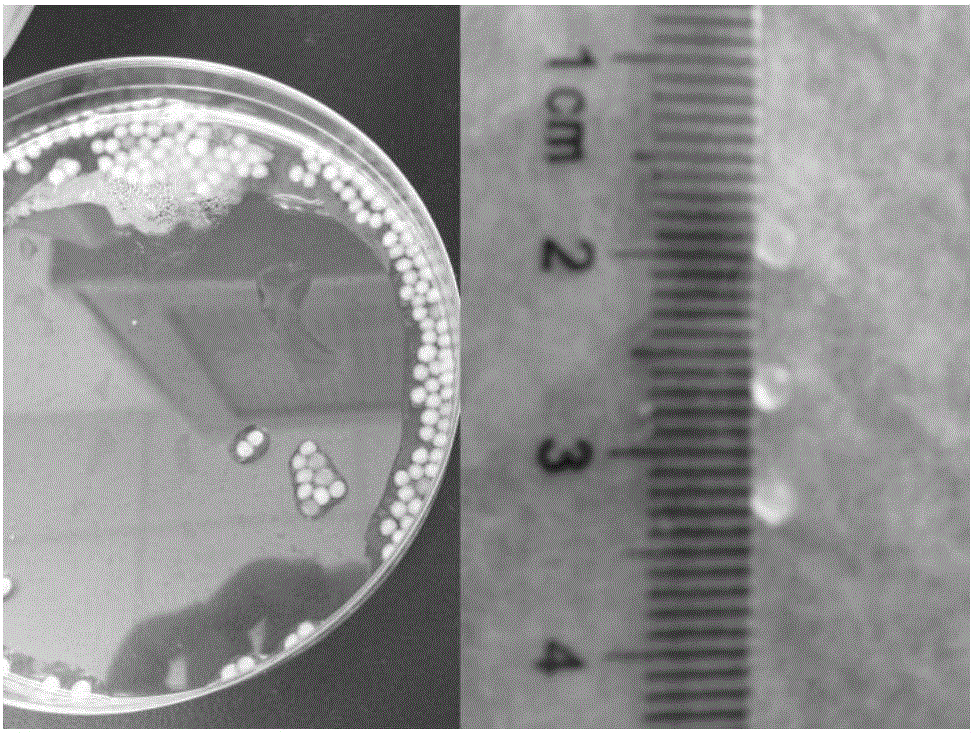

[0028] Embodiment 1: Preparation of calcium alginate / 5-Cl-PADAB microspheres

[0029] (1) Dissolve 0.2 g of sodium alginate in 20 mL of deionized water, stir to dissolve, and adjust the pH value to 6 with 0.01 mol / L hydrochloric acid solution to form a sodium alginate solution;

[0030] (2) Add 0.175g ethyldimethylaminopropylcarbodiimide (EDC) and 0.099g N-hydroxysulfosuccinimide (sulf-NHS) successively to sodium alginate solution, and stir magnetically for 15min at room temperature , fully mixed to obtain a mixed solution;

[0031] (3) 0.050g5-Cl-PADAB was dissolved in 25mL dimethyl sulfoxide (DMSO) solution to form a mixed solution of dimethyl sulfoxide, which was then added to the mixed solution obtained in step (2), and used Adjust the pH value to 7 with 0.01mol / L hydrochloric acid solution or 0.01mol / L sodium hydroxide solution, stir magnetically at room temperature for 24 hours, and mix thoroughly to obtain a mixed solution;

[0032] (4) After the mixed solution obtain...

Embodiment 2

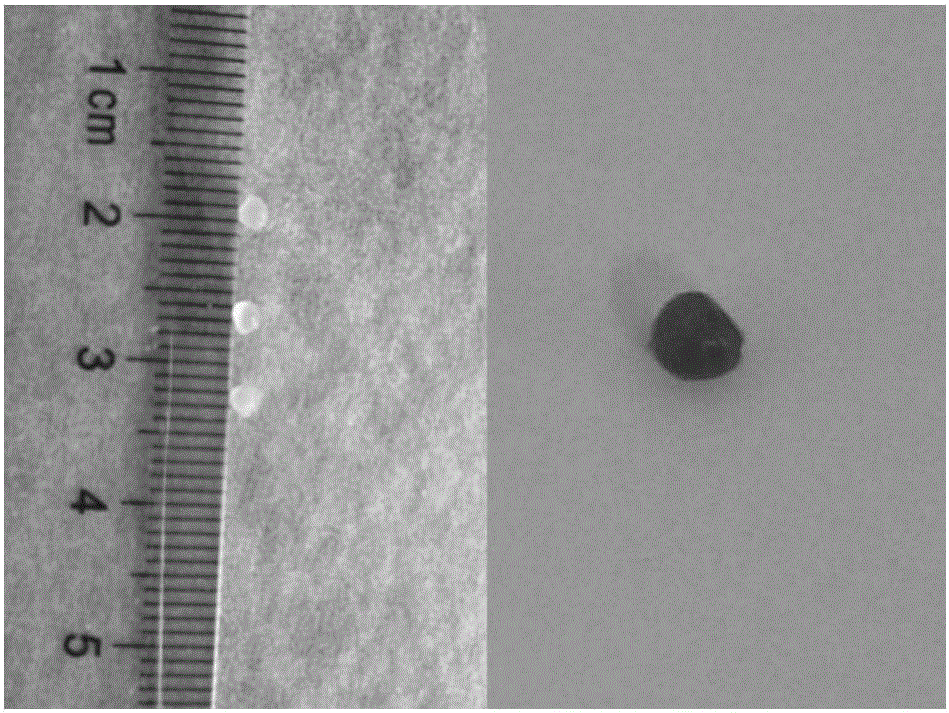

[0036] Get 1 calcium alginate / 5-Cl-PADAB microsphere that obtains in embodiment 1, join in containing 40mg / LCu 2+ In the solution, the calcium alginate / 5-Cl-PADAB microspheres changed from yellow to obvious red by naked eyes, and the calcium alginate / 5-Cl-PADAB microspheres adsorbed Cu 2+ before and after comparison figure 2 shown.

Embodiment 3

[0038] Take 0.5g calcium alginate / 5-Cl-PADAB microspheres (moisture content is about 85%) and add to 50mL containing Cu 2+ In the solution, after reacting for 1h, the flame atomic absorption method was used to determine Cu 2+ change in concentration. The test results showed that Cu 2+ The initial concentration was 36.87mg / L, and it was 5.51mg / L after 1h of reaction, and the removal rate was about 85%. 2+ The adsorption efficiency is about 20.87 mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com