Polyhedron cobalt phosphide/graphite carbon hybrid material and preparing method and application thereof

A hybrid material, cobalt phosphide technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as easy agglomeration, reduced catalytic activity and stability, and large phosphide size , to achieve high catalytic activity, low cost, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

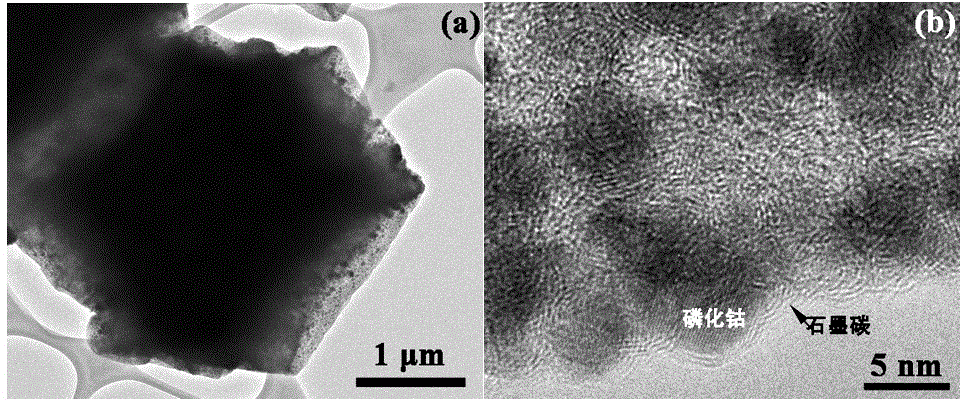

[0017] Embodiment 1, polyhedral cobalt phosphide / graphite carbon hybrid material and its preparation method and application, comprises the following steps:

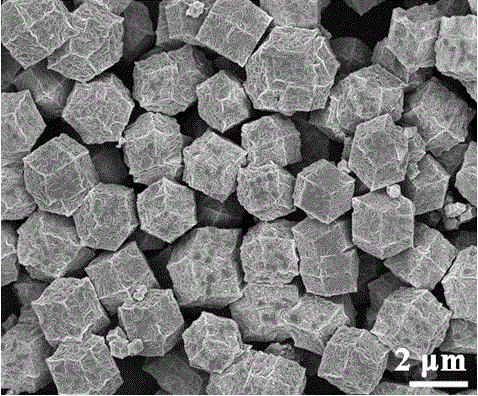

[0018] (1) Preparation of ZIF-67 template with polyhedral morphology: Weigh 1.46 g of cobalt nitrate hexahydrate and 1.64 g of 2-methylimidazole, dissolve them in 80 ml of methanol and ethanol mixed solution, stir and dissolve, and The cobalt nitrate solution was poured into the 2-methylimidazole solution. After stirring for 5 minutes, stand at room temperature for 24 hours, centrifuge the product, wash it twice with ethanol solution, and finally place it in a 60-degree drying oven. The obtained product is polyhedral ZIF-67. The product is blue-purple, mostly rhomboid dodecahedron in shape, and the particle size is about 1 micron.

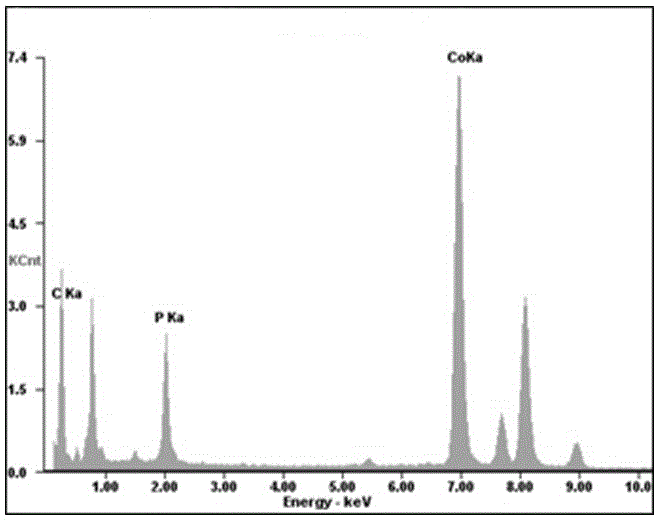

[0019] (2) Polyhedral cobalt phosphide / graphite carbon hybrid material and its preparation: Weigh 200 mg of ZIF-67 and 200 mg of red phosphorus and place them on both ends of the porcelain bo...

Embodiment 2

[0022] Embodiment 2, the preparation method of polyhedral cobalt phosphide / graphite carbon hybrid material, comprises the following steps:

[0023] (1) Preparation of ZIF-67 template with polyhedral morphology: Weigh 1.46 g of cobalt nitrate hexahydrate and 1.64 g of 2-methylimidazole, dissolve them in 150 ml of methanol and ethanol mixed solution, stir and dissolve, and The cobalt nitrate solution was poured into the 2-methylimidazole solution. After stirring for 1 minute, stand at room temperature for 24 hours, centrifuge the product, wash twice with ethanol solution, and finally place it in a 60-degree drying oven. The obtained product is polyhedral ZIF-67. The product is blue-purple in shape, mostly in the shape of rhombic dodecahedron, and the particle size is between 1 and 2 microns.

[0024] (2) Polyhedral cobalt phosphide / graphite carbon hybrid material and its preparation: Weigh 200 mg of ZIF-67 and 200 mg of red phosphorus and place them on both ends of the porcelai...

Embodiment 3

[0027] Embodiment 3, the preparation method of polyhedral cobalt phosphide / graphite carbon hybrid material, comprises the following steps:

[0028] (1) Preparation of ZIF-67 template with polyhedral morphology: Weigh 1.46 g of cobalt nitrate hexahydrate and 1.64 g of 2-methylimidazole, dissolve them in 200 ml of methanol and ethanol mixed solution, stir and dissolve, and The cobalt nitrate solution was poured into the 2-methylimidazole solution. After stirring for 5 minutes, stand at room temperature for 24 hours, centrifuge the product, wash it twice with ethanol solution, and finally place it in a 60-degree drying oven. The obtained product is polyhedral ZIF-67. The product is blue-purple, mostly rhomboid dodecahedron in shape, and the particle size is about 3 microns.

[0029] (2) Polyhedral cobalt phosphide / graphite carbon hybrid material and its preparation: Weigh 200 mg of ZIF-67 and 200 mg of red phosphorus and place them on both ends of the porcelain boat respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com