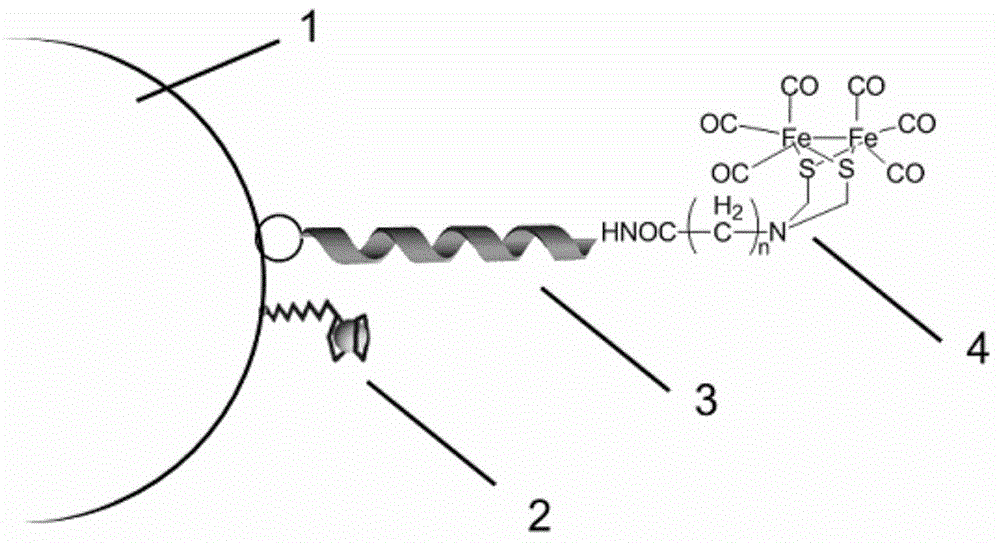

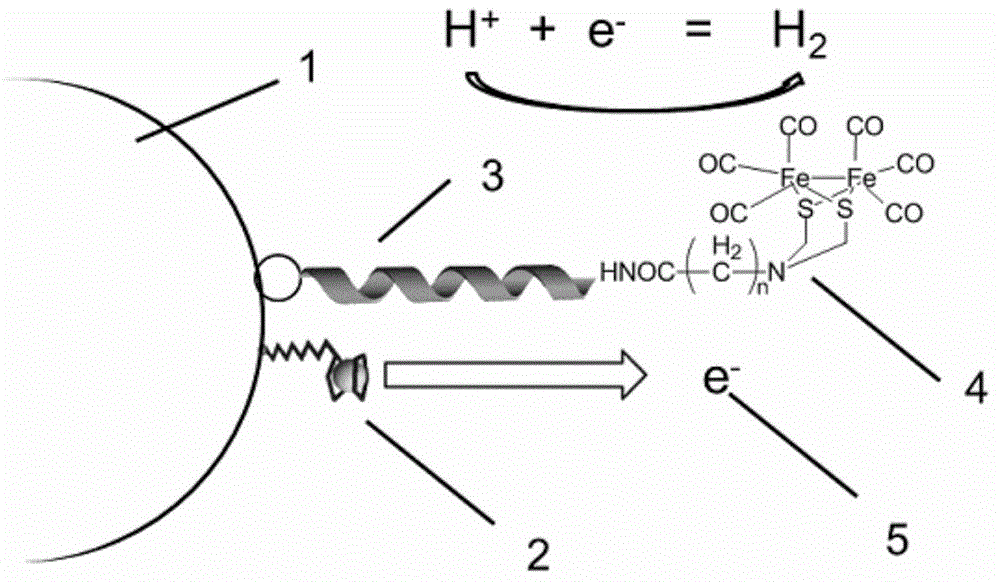

Hydrogen production nano-device, production method thereof, and hydrogen production method

A nano-device and metal nano-particle technology is applied in the field of nano-devices for preparing hydrogen, which can solve the problems of large electricity demand for electrolyzed water, achieve broad market application prospects, solve environmental pollution, and improve the effect of hydrogen yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In the preparation method of the present invention, the solvent is not particularly limited, and can be various solvents commonly used in the art. Preferably, the solvent is water or an organic solvent, and the organic solvent is N,N-dimethylformamide, trifluoro One or more of ethanol, methanol, ethanol, propanol, isopropanol, dimethylsulfoxide and chloroform. The corresponding solvent can be selected according to the amino acid sequence of the α-helical polypeptide, which is known to those skilled in the art and will not be repeated here.

[0035] In the preparation method of the present invention, preferably, based on the self-assembly reaction system, the concentration of metal nanoparticles is 0.5-20 mg / mL, more preferably 1-10 mg / mL; the concentration of α-helical polypeptide is 0.1-20 mg / mL; 10mM, more preferably 0.2-5mM; the molar ratio of α-helical polypeptide to photoelectron donor is 1:1-20, more preferably 1:5-15.

[0036] In the preparation method of the pr...

Embodiment

[0057] The following examples will further illustrate the present invention, but do not limit the present invention thereby.

[0058] In the following preparation examples, examples and comparative examples, unless otherwise specified, all reagents used are commercially available.

[0059] Polypeptide solid-phase synthesizer was purchased from CSBIO company, the model is CS136XT.

[0060] Gold nanoparticles are prepared by sodium citrate reduction method, the specific method includes: 100mL of 0.1% by weight chloroauric acid is heated to boiling with electromagnetic stirring, and then 5mL of 1% by weight of citric acid is added to obtain a 5.5mg / mL gold nanoparticle solution .

[0061] Silver nanoparticles were prepared by the traditional one-step reduction method of sodium citrate. The specific method included: mixing 100mL7.0×10 -3 M sodium citrate solution was added in a 250mL flask, stirred and heated to boiling, and then 1mL of 0.1M silver nitrate was added to obtain a ...

preparation example 1

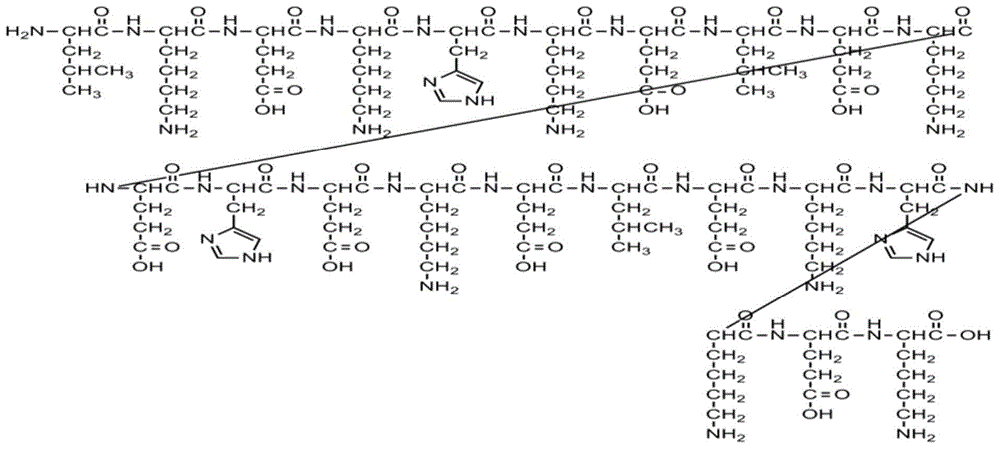

[0063] This preparation example is used to illustrate the preparation of α-helical polypeptides.

[0064] 0.5 g of Clear-acid resin (Clear-Acid Resin, purchased from Peptide Institute Inc.) and 5 mL of dichloromethane were placed in a polypeptide solid-phase synthesizer and shaken for 24 hours. After washing the resin with N,N-dimethylformamide (DMF), 3 mL of a DMF solution of 0.7 mM Fmoc-leucine (purchased from Peptide Institute Inc.), 0.7 mM N-hydroxy-7-azobenzotriazole Mix 1mL of DMF solution with 1mL of DMF solution of 0.7mM 1,3-diisopropylcarbodiimide, add it to the peptide solid-phase synthesizer, and mix it with the above resin, shake and react for 2 hours, the carboxyl group of leucine and the resin Condensation reaction of the amino group on the above-mentioned resin occurs, and Fmoc-leucine is fixed on the above-mentioned resin. After the reaction was completed, the resin was washed with DMF, and 5 mL of piperidine / DMF mixed solution (volume ratio of piperidine to D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com