A kind of carbon nanotube coil and its preparation method

A technology of carbon nanotube wires and carbon nanotubes, applied in the field of nanomaterial preparation, can solve the problem that carbon nanotube arrays cannot meet the requirements of high semiconductor selectivity and perfect structure, density and perfect structure cannot meet application conditions, and do not have semiconductor options To achieve the effect of tight connection, perfect structure and consistent chiral structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Will press with 0.1mol / L FeCl 3 The silicon substrate of the ethanol solution of the catalyst is placed in a substrate or a quartz boat and placed in a furnace reactor;

[0036] 2) Pass 200sccm of argon and hydrogen mixed inert gas (Ar:H2=1:2, v / v) into the reactor as a protective gas, and start to heat up, when the temperature rises to 900-1010°C, Constant temperature 20min. Then enter the reaction stage, pass into 180sccm methane and hydrogen mixed reaction gas (H 2 :CH 4 =2:1, v / v), start the ultra-long carbon nanotube preparation reaction, the reaction time is 10min-2h, the obtained single ultra-long carbon nanotube sample scanning electron microscope characterization result is as follows figure 1 As shown, the Rayleigh characterization map is as figure 2 As shown, the length standard is marked in the lower right corner of the picture. The diameter of carbon nanotubes tested is 0.6-5nm, and the length is 1mm-5m;

[0037] 3) At the later stage of the reactio...

Embodiment 2

[0040] 1) Will press with 0.1mol / L FeCl 3 The silicon substrate of the ethanol solution of the catalyst is placed in a substrate or a quartz boat and placed in a furnace reactor;

[0041] 2) Pass 200sccm of argon and hydrogen mixed inert gas (Ar:H2=1:2, v / v) into the reactor as a protective gas, and start to heat up, when the temperature rises to 900-1010°C, Constant temperature 20min. Then enter the reaction stage, pass into 180sccm methane and hydrogen mixed reaction gas (H 2 :CH 4 =2:1, v / v), start the ultra-long carbon nanotube preparation reaction, the reaction time is 10min-2h, the obtained ultra-long carbon nanotube has a diameter of 0.7-4nm and a length of 1-5m after detection;

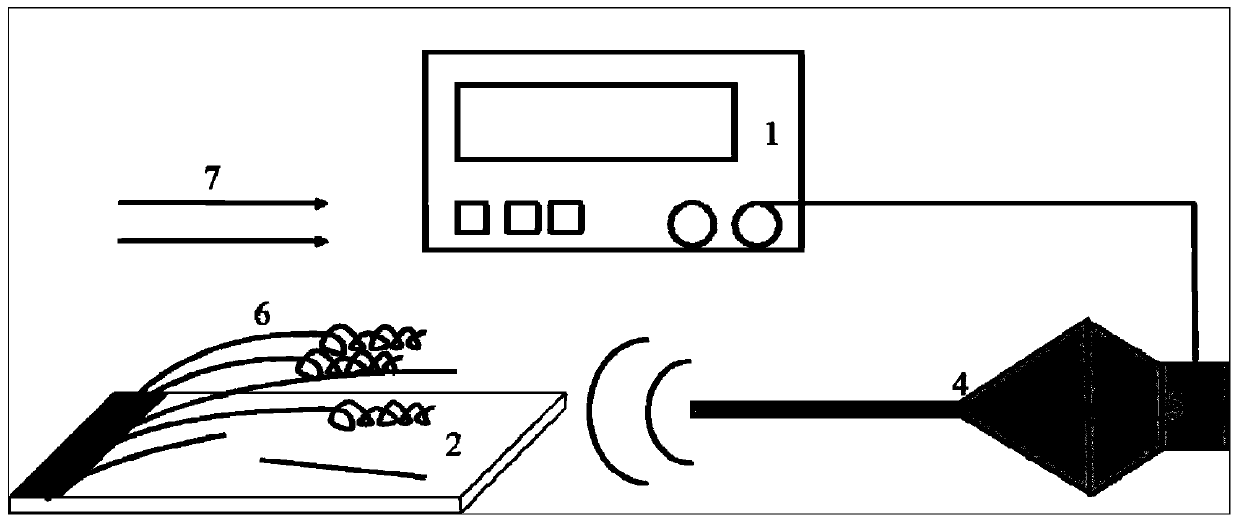

[0042] 3) At the later stage of the reaction, sound waves are added to the reactor, and the sound waves are formed by the electro-acoustic conversion device, which is constructed using the construction method in Example 1. The frequency of the electrical signal is controlled between 1-10kH...

Embodiment 3

[0045] 1) Will press with 0.1mol / L FeCl 3 The silicon substrate of the ethanol solution of the catalyst is placed in a substrate or a quartz boat and placed in a furnace reactor;

[0046] 2) Pass 200sccm of argon and hydrogen mixed inert gas (Ar:H2=1:2, v / v) into the reactor as a protective gas, and start to heat up. When the temperature rises to 1000°C, keep the temperature constant for 20min . Then enter the reaction stage, pass into 180sccm methane and hydrogen mixed reaction gas (H 2 :CH 4 =2:1, v / v), start the ultra-long carbon nanotube preparation reaction, the reaction time is 10min-2h, the obtained ultra-long carbon nanotube has a diameter of 5nm and a length of 5m after detection;

[0047] 3) At the later stage of the reaction, sound waves are added to the reactor, and the sound waves are formed by the electro-acoustic conversion device, which is constructed using the construction method in Example 1. The frequency of the electrical signal is controlled between 1-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com