Semi-closed two-chamber anaerobic reaction device and wastewater treatment method thereof

An anaerobic reaction device, semi-closed technology, applied in anaerobic digestion treatment, biological treatment devices, chemical instruments and methods, etc., can solve the problems of slow start-up speed, uniform water distribution, complex structure, etc. The effect of increasing the probability of contact and improving the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

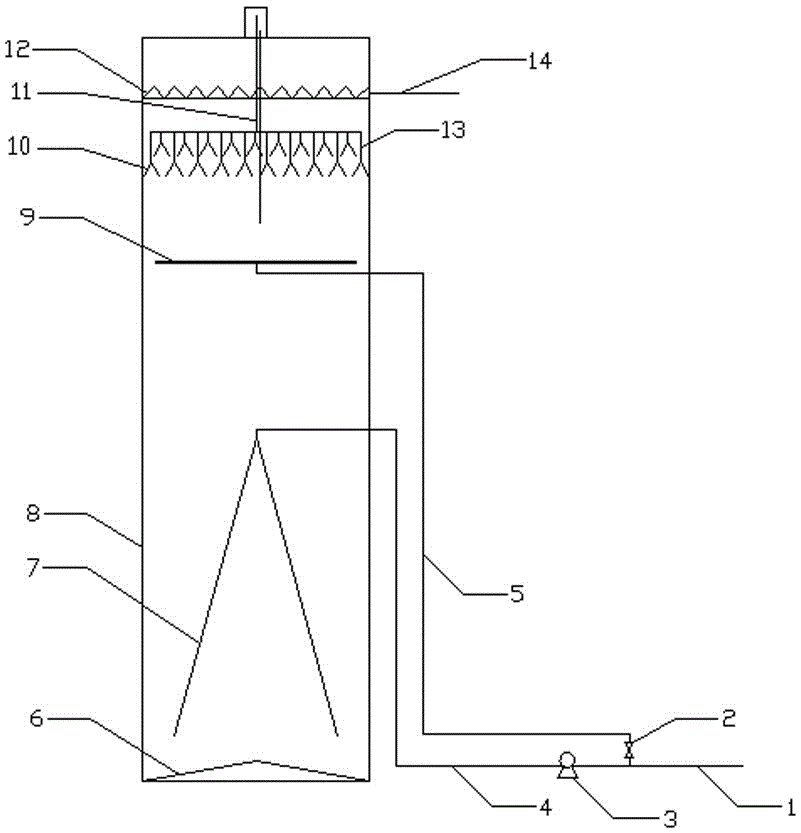

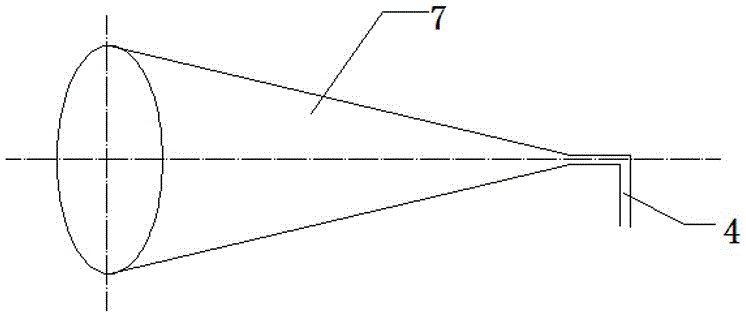

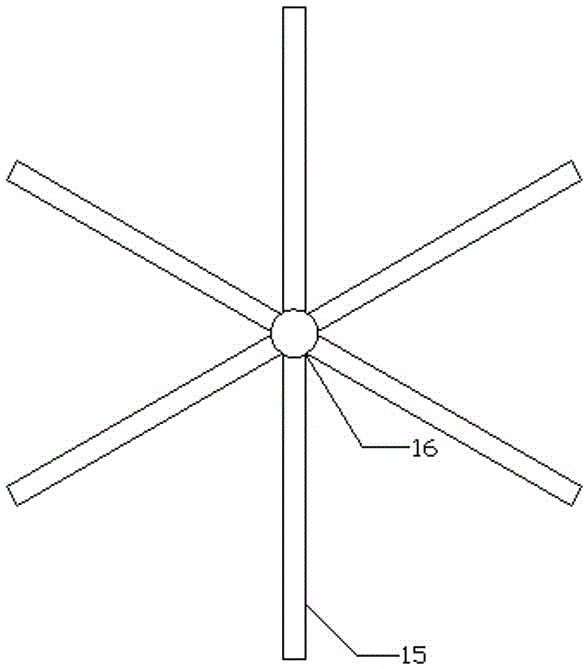

[0025] Example 1: The invention provides a semi-enclosed two-chamber anaerobic reaction device, the schematic diagram of which is as follows figure 1 As mentioned above, its basic device includes a main reactor 8 and a water inlet system. The water pump 3 is connected between the front pipe 1 of the water inlet pump and the water inlet pipe 4 , and the other end of the water inlet pipe 4 leads into the main reactor 8 . The main reactor 8 is the main pool wall of the anaerobic reactor, mostly cylindrical in shape, steel concrete or steel structure, with anti-corrosion measures on the inner wall, and generally an insulating layer on the outside. The water inlet system includes the water inlet pipe 4, the front pipe 1 of the water inlet pump and the water pump 3. The rated flow rate of the water pump 3 is 2-4 times of the designed water inlet, and the head is determined according to the liquid level height of the reactor. On the basis of this structure, the present invention is ...

Embodiment 2

[0041] Example 2: The present invention provides a semi-enclosed two-chamber anaerobic reaction device, the structure of which is basically the same as in Example 1, the difference being that the apex angle of the central cone is 45°, the diameter of the distribution main pipe is 250 mm, and the three-phase separator layer The spacing is 200mm, and steel plates and anti-corrosion measures are used.

[0042] In the process of wastewater treatment in this embodiment, the flow velocity at the outlet at the top of the central cone is 6.7m / s, the descending flow velocity at the bottom of the central cone is 7.3m / h, and the flow velocity at the bottom of the pool is 20.2m / h. The ascending flow rate in the main reactor is 5.2m / h.

[0043] The anaerobic reaction device and the wastewater treatment process in this example are applied to the wastewater in the production of a food enterprise. The pH of the wastewater is 7.2; SS: 3600-8500mg / L; COD: 16500-23000mg / L, which is high concen...

Embodiment 3

[0044] Example 3: The present invention provides a semi-enclosed two-chamber anaerobic reaction device, the structure of which is basically the same as in Example 1, the difference being that the apex angle of the central cone is 35°, the diameter of the distribution main pipe is 300mm, and the three-phase separator layer The spacing is 180mm.

[0045] In the process of wastewater treatment in this embodiment, the flow velocity at the outlet at the top of the central cone is 8.5m / s, the descending flow velocity at the bottom of the central cone is 6.6m / h, and the flow velocity at the bottom of the pool is 25.4m / h. The rising velocity in the main reactor is 4.8m / h.

[0046] The anaerobic reaction device and the process of treating waste water in this example are applied to the waste water in the production of a certain pharmaceutical company. The pH of the waste water: 7-9; SS: 1200-3600mg / L; COD: 9600-14300mg / L, which is high Concentrated organic wastewater has a certain bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com