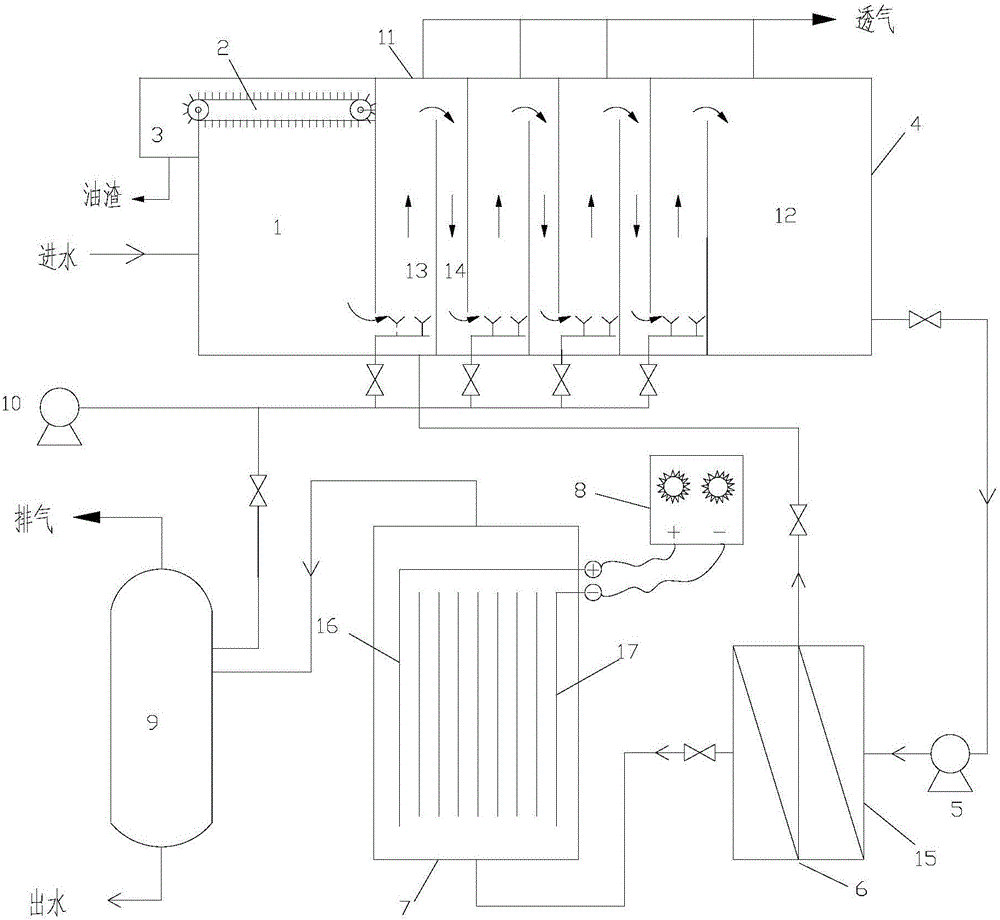

Offshore platform domestic sewage treatment system and method using biochemical electrolytic method

A technology for domestic sewage and offshore platforms, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sewage treatment equipment, etc. System load impact and other problems, to improve water inlet conditions, save operation and maintenance costs, and improve impact load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

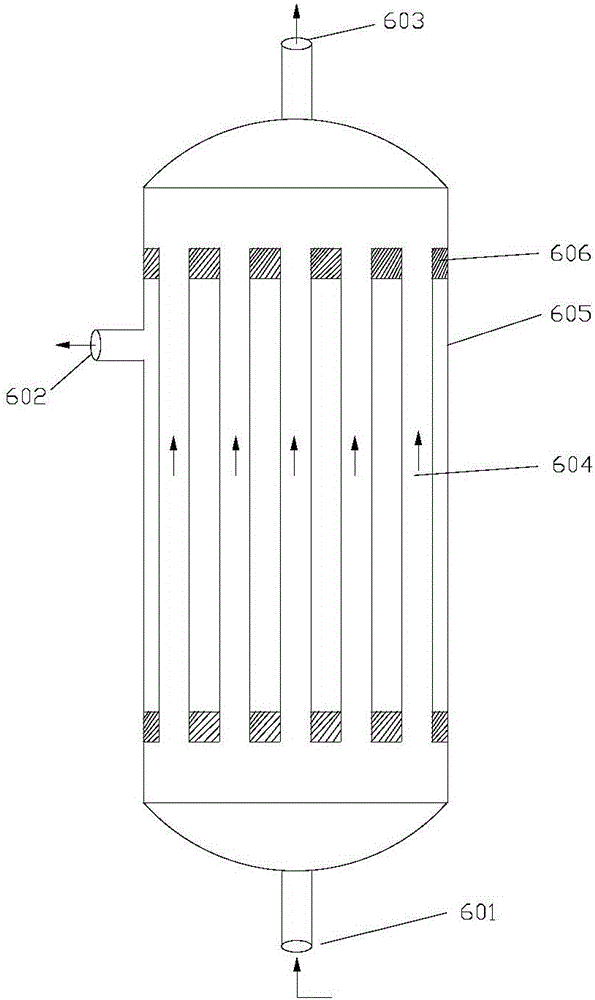

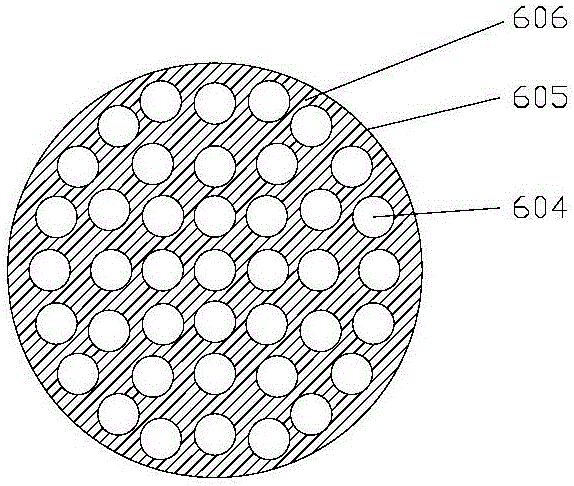

[0022] An offshore oil platform in the South China Sea adopts the biochemical combined electrolysis treatment system and method of the present invention to treat domestic sewage on the platform, and the sewage water volume is about 72m 3 / d. The domestic sewage on the platform enters the buffer pool 1, the biochemical pool 4, the membrane filtration unit 6, and the electrolytic catalytic oxidation device 7 sequentially according to the above-mentioned embodiment, and stays in the biochemical pool 4 for 3 hours. The operating pressure of the membrane filtration unit is 0.16Mpa, and the DC power supply current The size is 600A and the voltage is 34V. The influent COD of domestic sewage on the platform is about 787-1026mg / L, the conductivity is 20000-25000us / cm, and the concentration of chloride radicals is 8000-15000mg / L. After being treated by the biochemical combined electrolysis treatment system of the present invention, the effluent COD is 100 ~237mg / L, BOD 20~22mg / L, SS 20...

Embodiment 2

[0024] For an offshore oil platform in Bohai Sea, the domestic sewage of the platform is treated by biochemical method, and the domestic sewage generated on the platform is about 63m 3 / d. With the improvement of domestic sewage discharge requirements on offshore platforms, the existing sewage treatment devices on the platform cannot meet the actual production needs. Therefore, the platform has undergone domestic sewage upgrading and transformation, and the biochemical combined electrolysis treatment system and method of the present invention are used to treat the platform domestic sewage. The domestic sewage enters the buffer pool 1, the biochemical pool 4, the membrane filtration unit 6 and the electrolytic catalytic oxidation device 7 sequentially according to the above-mentioned specific implementation method, and stays in the biochemical pool 4 for 3.5 hours. The operating pressure of the membrane filtration unit is 0.2Mpa, and the DC power is applied The current size is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com