Gasoline cleansing agent containing friction modifier and capable of saving fuel oil and preparation method of gasoline cleansing agent

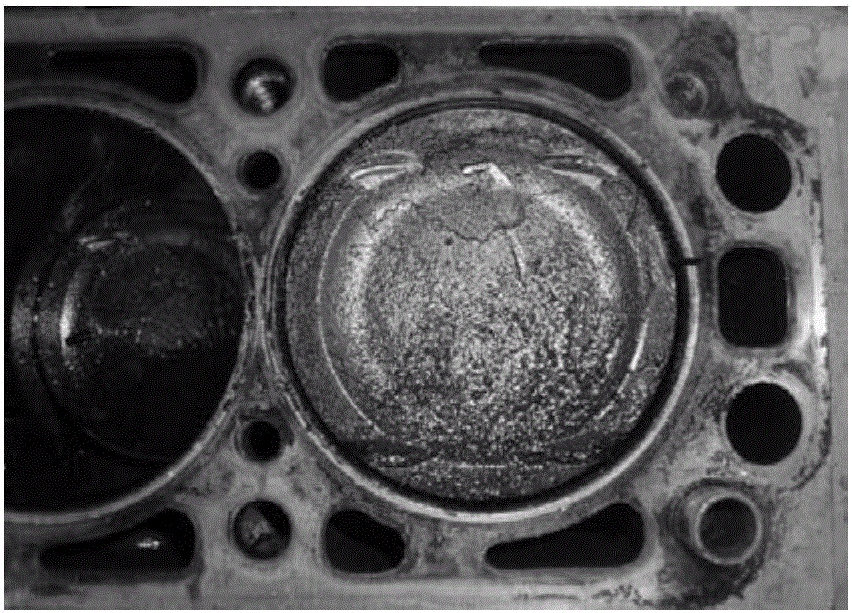

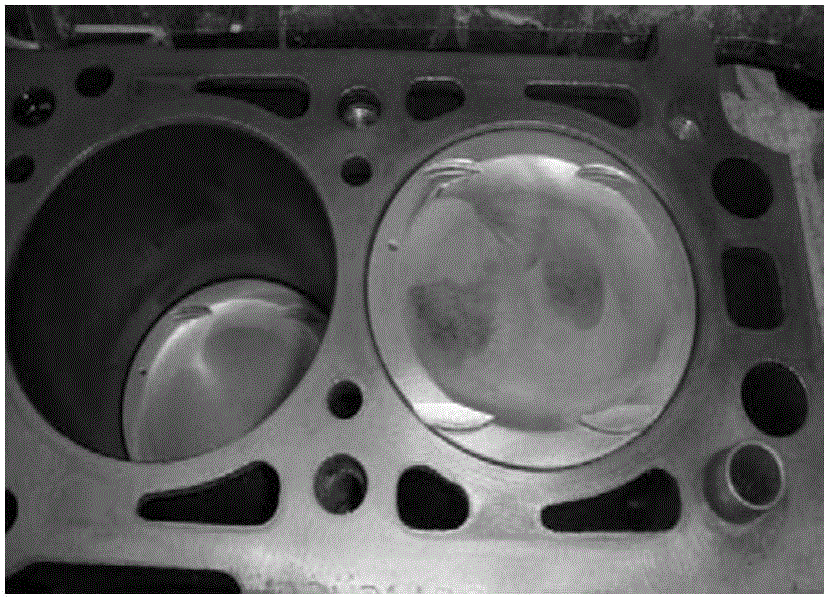

A friction modifier and gasoline detergent technology, applied in the field of fuel additives, can solve the problems of poor lubrication conditions of the upper part of the piston and the piston ring, and achieve the effects of convenient storage and stable physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0047] According to the ratio of raw materials in Table 1 and according to the following method to prepare fuel-saving gasoline detergent containing friction modifier.

[0048] (1) Add carrier oil, diluent, detergent, and dispersant to the reaction kettle in sequence and heat to 55°C while stirring, and stir for 0.5h to mix evenly;

[0049] (2) Add friction modifier, antioxidant, rust inhibitor, demulsifier, keep warm and stir for 0.5h to mix evenly;

[0050] (3) Cool down to 40°C, add an octane number improver, stir for 1 hour, filter through a 5 μm filter, and release to obtain the product.

[0051] Table 1: Raw material ratio table of embodiment 1-4

[0052]

Embodiment 5

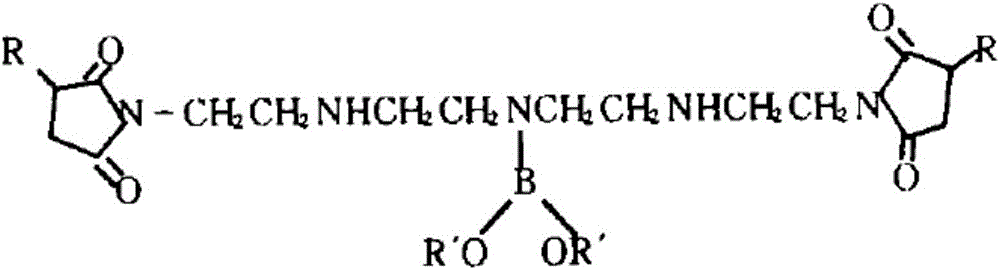

[0054]Raw material (mass percentage) of fuel-saving gasoline detergent containing friction modifier: 40% of Mannich base, 7% of borated polyisobutylene succinimide, 8% of ethyl tert-butyl ether, N,N-di( 12) Molybdenum alkyl dithiocarbamate 4.5%, antioxidant 0.4%, dodecenyl succinic acid 2.2%, simethicone 0.1%, dimethyl carbonate 15%, the balance is azelaic acid Bis(2-ethylhexyl) ester.

[0055] The antioxidant is obtained by uniformly stirring and mixing 50 wt% of 4,4'-dioctyl dianiline and 50 wt% of 4,4'-dimethyl dianiline.

[0056] Preparation of fuel-saving gasoline detergent containing friction modifier:

[0057] (1) Add bis(2-ethylhexyl) azelate, dimethyl carbonate, Mannich base, and borated polyisobutylene succinimide in turn to the reaction mixing kettle and heat to 55°C, 400 rpm Stir for 0.5h to mix evenly;

[0058] (2) Add molybdenum N,N-di(dodecyl)alkyldithiocarbamate, antioxidant, dodecenylsuccinic acid, and simethicone, at a temperature of 55°C, and stir at 400 ...

Embodiment 6

[0061] A fuel-saving gasoline detergent containing a friction modifier was prepared according to the method of Example 5, except that the antioxidant was only 4,4'-dioctyldiphenylamine. The fuel-saving gasoline detergent containing the friction modifier of Example 6 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com