Double-chamber microfiltration membrane multi-anode microalgae biofuel cell

A technology of microalgae and fuel cells, applied in biochemical fuel cells, fuel cell parts, battery electrodes, etc., can solve the problems of high cost and low power, and achieve improved performance, wide distribution, and strong tolerance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

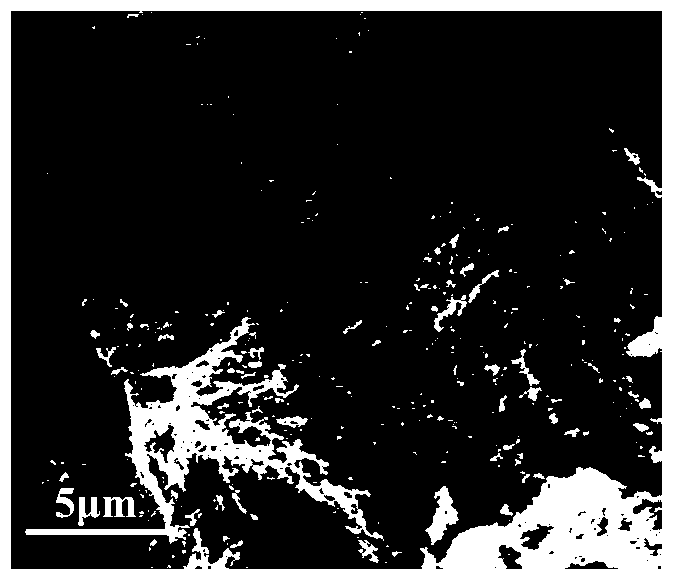

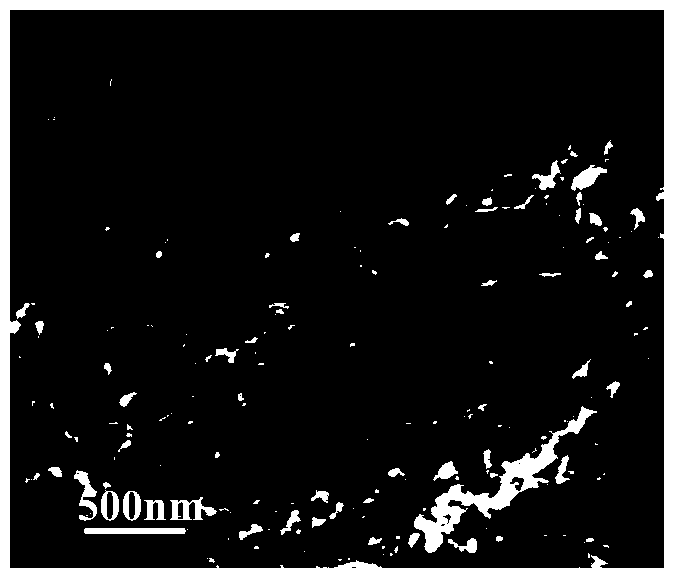

Image

Examples

Embodiment 1

[0036] Double-chamber microfiltration membrane multi-anode microalgae biofuel cell, including: anode plate 1, anode fixing frame 2, anode chamber 3, diaphragm 4, cathode chamber 5, cathode plate 6 and cathode fixing plate 7;

[0037] The diaphragm 4 separates the anode chamber 3 and the cathode chamber 5; the anode chamber 3 is a square pool with the top removed, and a through hole is opened on one side wall of the pool; the anode holder 2 fixed with the anode plate 1 is inserted into the anode Chamber 3, the packaging of the top of the anode chamber 3 can be realized; a sheet with a through hole in the middle and a liquid injection channel on the top is inserted between the cathode plate 6 and the diaphragm 4 as the cathode chamber 5, and the cathode plate 6 passes through the cathode fixing plate 7 is fixed; a through hole is opened in the middle of the cathode fixing plate 7;

[0038] The diaphragm 4 is a slow qualitative filter paper or a microfiltration membrane;

[0039...

Embodiment 2

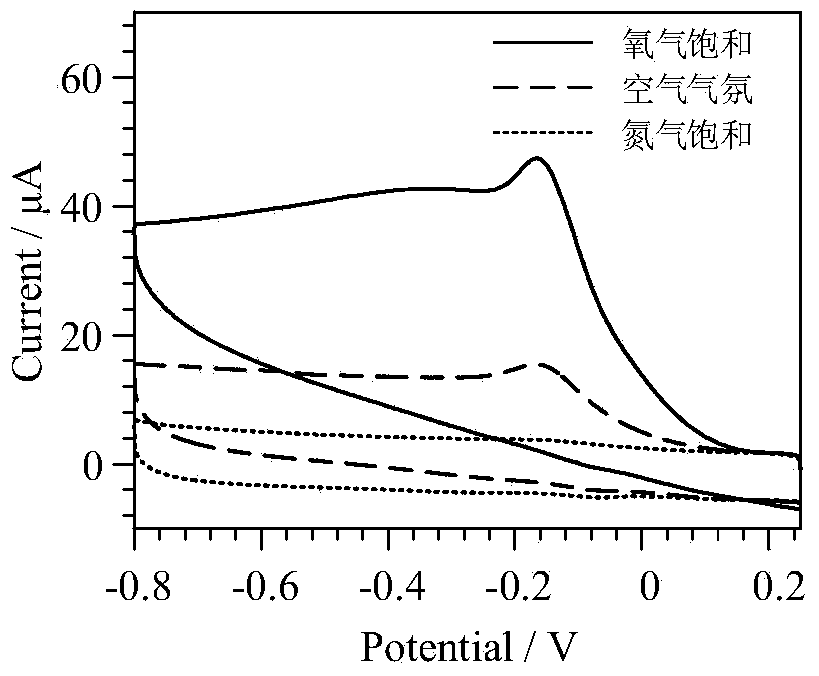

[0053] Using Chlorella common seawater as the working algae species, a double-chamber multi-anode microalgae biofuel cell reactor was assembled using a proton exchange membrane instead of microporous filter paper. The test process was the same as in Example 1, and the measurement results were as follows: Figure 4 shown. The maximum output power of a single reactor is 29μW. By comparing with Example 1, it can be seen that the practical application effect of the double-chamber microfiltration membrane multi-anode microalgae biofuel cell proposed by the present invention is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com