Preparation method of polyelectrolyte microcapsules

A technology of polyelectrolyte and hydrophobic substances, which is applied in the field of preparation of polyelectrolyte microcapsules, and can solve problems such as difficulties in practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of polyelectrolyte microcapsule, comprises the following steps:

[0030] A) mixing an organic solution of a hydrophobic substance, an emulsifier, and a first polyelectrolyte in water to obtain an emulsion, and the first polyelectrolyte is an anionic polyelectrolyte or a cationic polyelectrolyte;

[0031] The anionic polyelectrolyte includes one or more of polyacrylic acid, carboxymethyl cellulose, sodium alginate, sulfonated cellulose and sodium polystyrene sulfonate;

[0032] The cationic polyelectrolyte includes one or more of polylysine, chitosan, cationic starch, polyallylamine hydrochloride and polydiallyldimethylammonium chloride;

[0033] B) dripping the emulsion in the step A) into the aqueous solution of the second polyelectrolyte to obtain polyelectrolyte microcapsules;

[0034] The ionizable groups of the first polyelectrolyte and the second polyelectrolyte are oppositely charged.

[0035] The preparation ...

Embodiment 1

[0045] 1. Dissolving the hydrophobic drug indomethacin in chloroform to form an oil phase with a mass concentration of 20%; the emulsifier Tween 80 and the anionic polyelectrolyte carboxymethyl cellulose with a weight average molecular weight of 100,000 Mixed in water, the mass concentrations of Tween 80 and carboxymethyl cellulose are 0.2% and 0.5% respectively. Then the above two components are mixed and emulsified to form a stable O / W emulsion;

[0046] 2. Dissolving deacetylated chitosan with a weight average molecular weight of 100,000 in water to prepare an aqueous solution with a mass concentration of 2%;

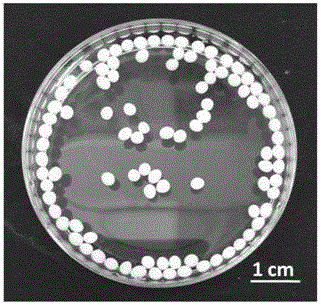

[0047] 3. Drop the emulsion prepared in step 1 into the aqueous solution prepared in step 2 to obtain polyelectrolyte microcapsules encapsulating the indomethacin emulsion. The average size of the microcapsules is 1.5 mm.

[0048] The polyelectrolyte microcapsules wrapped with indomethacin emulsion prepared in this example had a drug loading capacity of 68.2% and an...

Embodiment 2

[0050] 1. Dissolve the hydrophobic drug nifexinidine in toluene to form an oil phase with a mass concentration of 5%; the emulsifier Span 80 and the anionic polyelectrolyte cellulose sulfonate with a weight average molecular weight of 300,000 are mixed in water, The mass concentrations of Span 80 and cellulose sulfonate are 0.5% and 3% respectively. Then the above two components are mixed and emulsified to form a stable O / W emulsion;

[0051] 2. Dissolve polydiallyldimethylammonium chloride with a weight average molecular weight of 600,000 and polyallylamine hydrochloride with a weight average molecular weight of 200,000 in water, and the mass concentration of both is 2.5%. , preparing an aqueous solution with a total mass concentration of 5%;

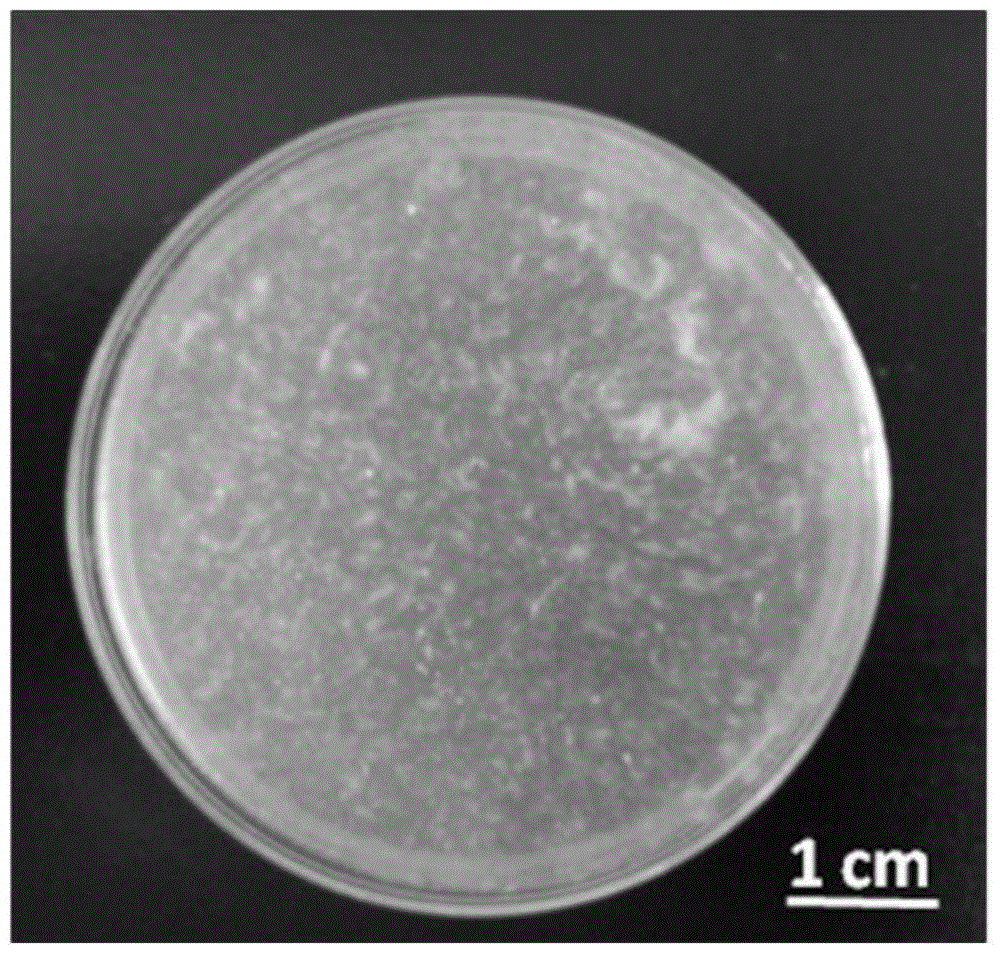

[0052] 3. Drop the emulsion prepared in step 1 into the aqueous solution prepared in step 2 to obtain polyelectrolyte microcapsules wrapped with nifedipine emulsion. The average size of the microcapsules is 3.0 mm.

[0053] The polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com