Welding wire special for 7XXX series aluminum alloy and manufacturing method thereof

A manufacturing method and aluminum alloy technology, which is applied in the field of aluminum alloy processing, can solve problems such as cracks in welded joints, cracks in welded joints, and unsuitable welding wires, etc., and achieve the effects of avoiding welding cracks, improving weldability, high strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

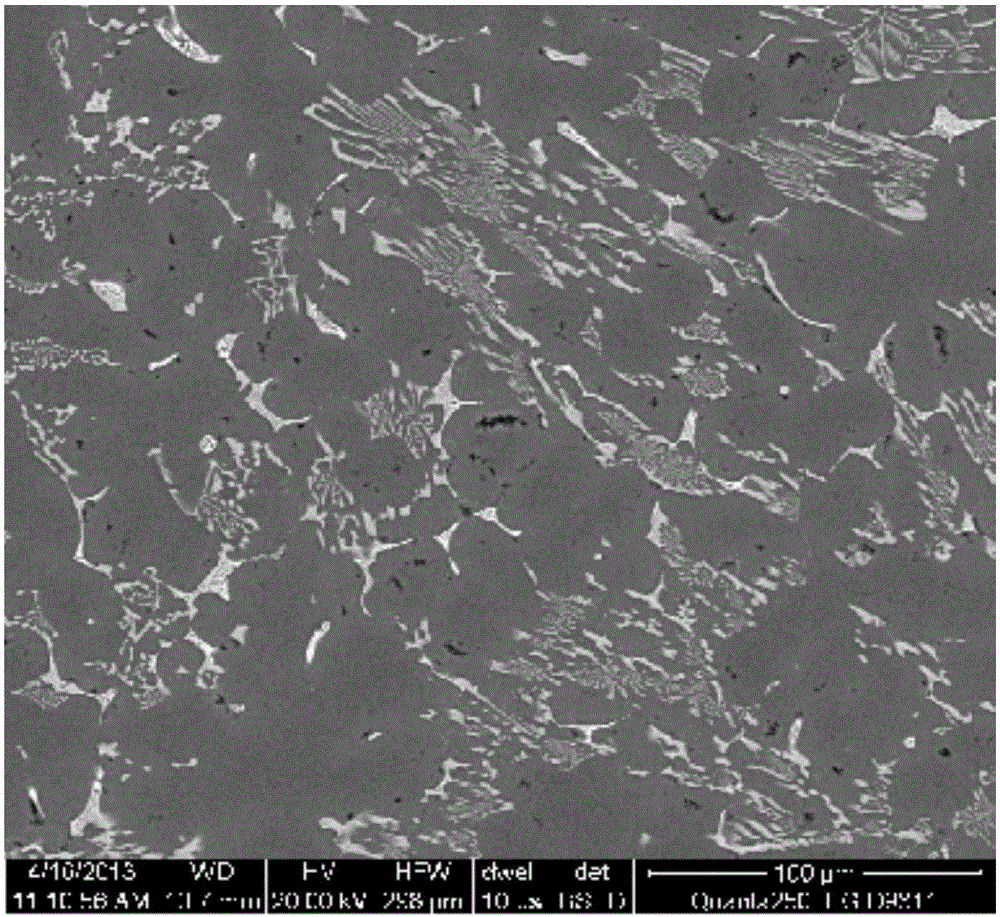

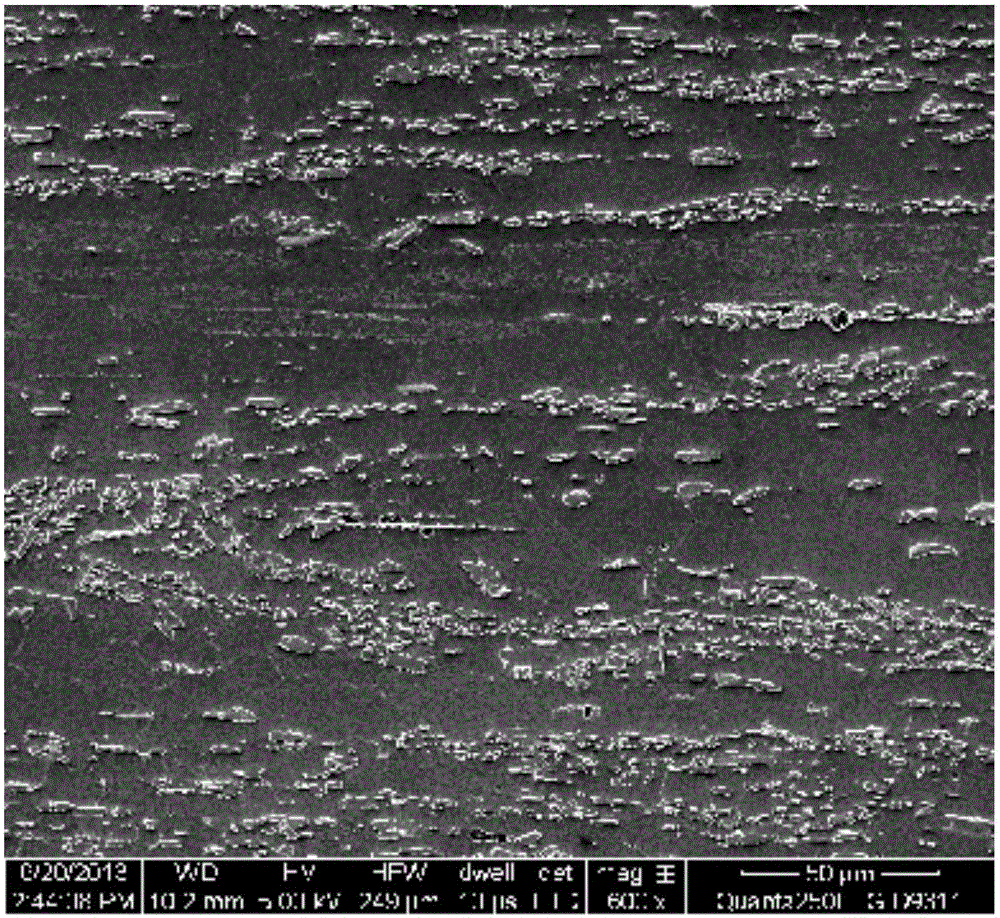

Image

Examples

Embodiment 1

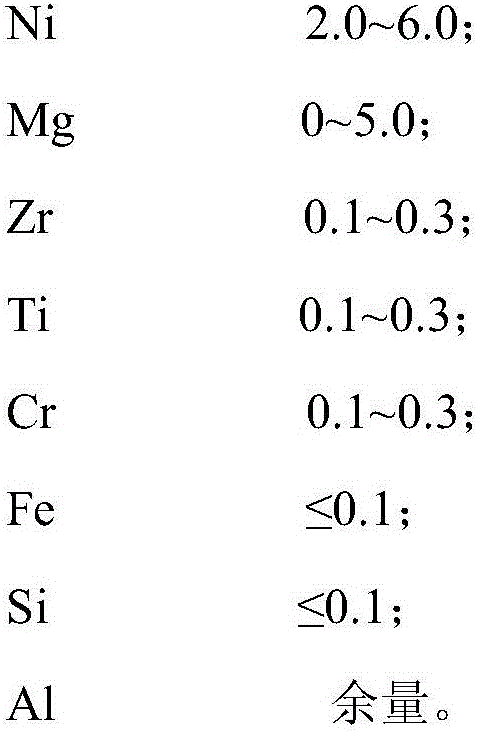

[0032] The chemical composition (mass fraction) of aluminum alloy welding wire: Ni6%, Zr0.1%, Cr0.1%, Ti0.1%, Fe0.1%, Si0.1%, Al and the rest.

[0033] Preparation method of aluminum alloy welding wire:

[0034] (1) Melting aluminum-nickel master alloy, aluminum-zirconium master alloy, aluminum-titanium master alloy, aluminum-chromium master alloy and high-purity aluminum ingot according to the ratio of ingredients, the content of aluminum in the high-purity aluminum ingot is at least 99.98%.

[0035] (2) Sampling analysis, after the chemical composition of the aluminum alloy is all qualified, it is treated with electromagnetic stirring and vacuum purification. The electromagnetic power is 10KW. After the end, remove the slag and wait for pouring.

[0036] (3) Apply graphite paint to the crystallizer, start semi-continuous casting, and make an ingot of 7XXX aluminum alloy special welding wire. Semi-continuous casting process parameters are as follows:

[0037] Pouring tempe...

Embodiment 2

[0046]The chemical composition (mass fraction) of aluminum alloy welding wire: Ni3%, Mg5.0%, Zr0.3%, Cr0.3%, Ti0.3%, Fe0.060%, Si0.022%, Al and the rest.

[0047] Preparation method of aluminum alloy welding wire:

[0048] (1) Melt aluminum-nickel master alloy, aluminum-zirconium master alloy, aluminum-titanium master alloy, aluminum-chromium master alloy and high-purity aluminum ingot according to the proportion of ingredients. After the aluminum ingot is completely melted, add pure magnesium and high-purity aluminum ingot The aluminum content is at least 99.98%.

[0049] (2) Sampling and analysis, after the chemical composition of the aluminum alloy is all qualified, it is treated with electromagnetic stirring and vacuum purification. During electromagnetic stirring, the electromagnetic power is 20KW, the flow speed of aluminum liquid is 5m / min, the vacuum degree is 267Pa, and the processing time is 30min. After the end, remove the slag and wait for pouring.

[0050] (3) A...

Embodiment 3

[0060] Chemical composition (mass fraction) of aluminum alloy welding wire: Ni3%, Mg4%, Zr0.15%, Cr0.15%, Ti0.15%, Fe0.04%, Si0.06%, Al and the rest.

[0061] Preparation method of aluminum alloy welding wire:

[0062] (1) Melt aluminum-nickel master alloy, aluminum-zirconium master alloy, aluminum-titanium master alloy, aluminum-chromium master alloy and high-purity aluminum ingot according to the proportion of ingredients. After the aluminum ingot is completely melted, add pure magnesium and high-purity aluminum ingot The aluminum content is at least 99.98%.

[0063] (2) Sampling analysis, after the chemical composition of the aluminum alloy is all qualified, it is treated with electromagnetic stirring and vacuum purification. When electromagnetic stirring is performed, the electromagnetic power is 15KW, the flow rate of aluminum liquid is 3m / min, the vacuum degree is 220Pa, and the processing time is 30min. After the end, remove the slag and wait for pouring.

[0064] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com