Method for preparing iron disulfide

A technology of iron disulfide and magnetic iron oxide, applied in iron sulfide, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of high cost and achieve the effects of improving yield, simple operation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method for preparing iron disulfide described in the present embodiment may further comprise the steps:

[0026] Add 16g of magnetic iron oxide Fe to the reactor 21.333 o 32 and 10.2mL of 30wt% hydrogen peroxide, mix well and then pass into the reactor containing H 2 S40000ppm nitrogen, keep the pressure in the reactor at 2MPa, and the gas at the outlet of the reactor does not contain H 2 S time means that the reaction is complete, and 24g of iron disulfide is obtained.

Embodiment 2

[0028] The method for preparing iron disulfide described in the present embodiment may further comprise the steps:

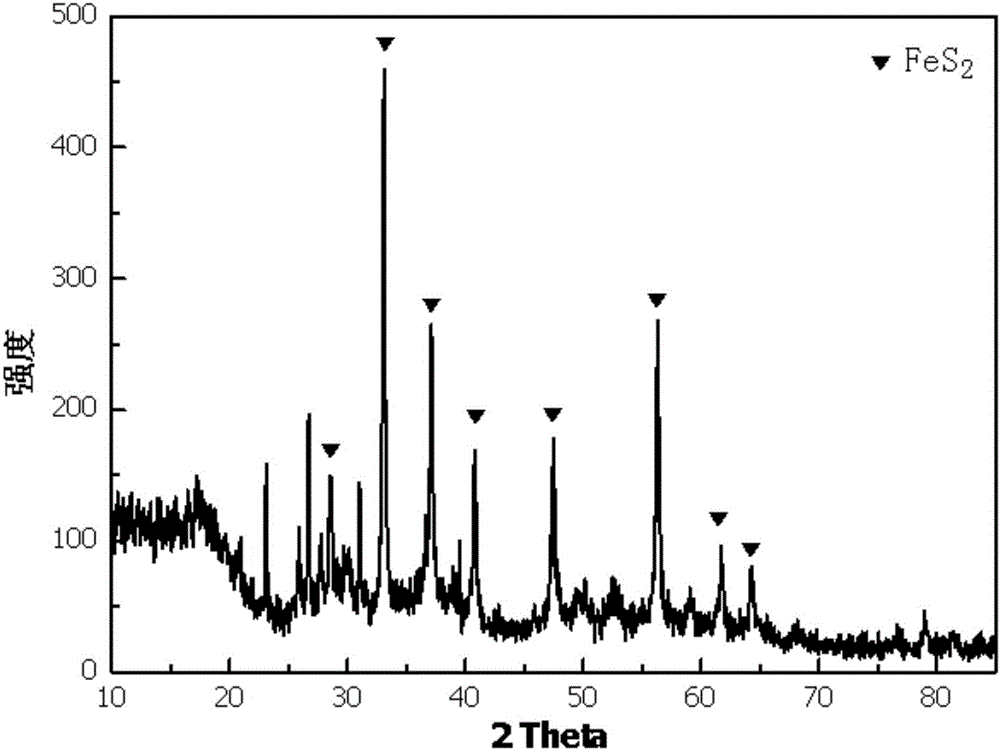

[0029] Add 20g of magnetic iron oxide Fe to the reactor 21.333 o 32 Desulfurization agent and 5g sodium percarbonate, after mixing, the reactor is heated to 125°C and filled with H 2 The nitrogen of S40000ppm, keep the pressure in the reactor to be 0.05MPa, after the desulfurizer is saturated and desulfurized, the iron disulfide hydrogenation catalyst is obtained, and its X-ray polycrystalline powder diffraction pattern is as follows figure 1 shown.

Embodiment 3

[0031] Add 30g of magnetic iron oxide Fe to the reactor 21.333 o 32 Desulfurizer and 10g tert-butyl hydroperoxide, after mixing, control the temperature of the reactor to 20°C and feed 2 S40000ppm of nitrogen, keep the pressure in the reactor at 0.1MPa, and obtain the iron disulfide hydrogenation catalyst after the desulfurizer is saturated and desulfurized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com