Eu3+/Yb3+ co-doped silicate glass ceramics and preparation method and application thereof

A technology of glass-ceramic and silicate, which is applied in glass manufacturing equipment, glass forming, manufacturing tools, etc., can solve the problems of low photoelectric conversion efficiency, achieve good spectral conversion effect, good glass forming ability, and low volatility little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

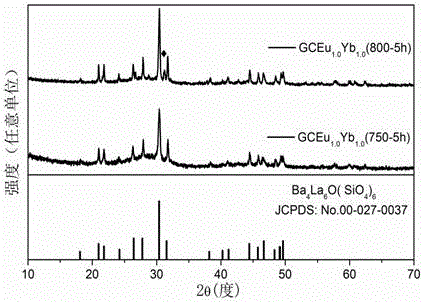

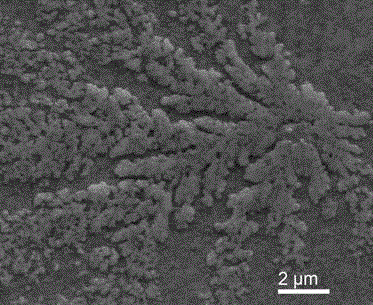

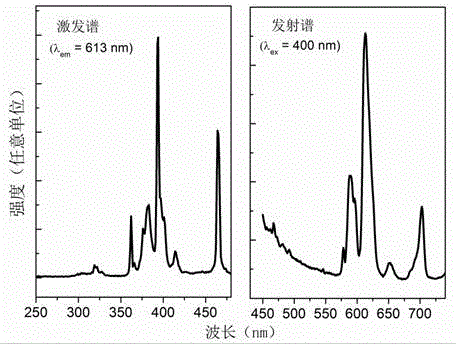

[0034] Eu 3+ / Yb 3+ The preparation of the co-doped glass-ceramic material, the steps are as follows:

[0035] (1) The basic composition (mole percentage) of glass-ceramics is: 30% SiO 2 , 20%SrO, 30%BaO, 10%B 2 o 3 ,5%La 2 o 3 , 5%Al 2 o 3 ; The doping composition is P 2 o 5 、Eu 2 o 3 and Yb 2 o 3 , P 2 o 5 The dosage is 1% of the base composition, Eu 2 o 3 The dosage is 0.5% of the base composition, Yb 2 o 3 The dosage is 0.5% of the base composition. According to the composition, analytically pure silicon dioxide, strontium carbonate, barium carbonate, boric acid, lanthanum oxide, aluminum oxide, ammonium dihydrogen phosphate, europium oxide, and ytterbium oxide were accurately weighed and mixed to obtain 30 g of batch materials. Fully grind and mix the batch materials in an agate mortar, then put them into a 50ml corundum crucible, place them in a high-temperature furnace at 1400°C for 1.5 hours, and obtain a homogenized melt. The melt was poured onto ...

Embodiment 2

[0042] Eu 3+ / Yb 3+ The preparation of the co-doped glass-ceramic material, the steps are as follows:

[0043] (1) The basic composition (mole percentage) of glass-ceramics is: 30% SiO 2 , 20%SrO, 30%BaO, 10%B 2 o 3 ,5%La 2 o 3 , 5%Al 2 o 3 ; The doping composition is P 2 o 5 、Eu 2 o 3 and Yb 2 o 3 , P 2 o 5 The dosage is 1% of the base composition, Eu 2 o 3 The dosage is 0.5% of the base composition, Yb 2 o 3 The dosage is 1.0% of the base composition. According to the composition, analytically pure silicon dioxide, strontium carbonate, barium carbonate, boric acid, lanthanum oxide, aluminum oxide, ammonium dihydrogen phosphate, europium oxide, and ytterbium oxide were accurately weighed and mixed to obtain 30 g of batch materials. Fully grind and mix the batch materials in an agate mortar, then put them into a 50ml corundum crucible, place them in a high-temperature furnace at 1400°C for 1.5 hours, and obtain a homogenized melt. The melt was poured onto ...

Embodiment 3

[0048] Eu 3+ / Yb 3+ The preparation of the co-doped glass-ceramic material, the steps are as follows:

[0049] (1) The basic composition (mole percentage) of glass-ceramics is: 30% SiO 2 , 20%SrO, 30%BaO, 10%B 2 o 3 ,5%La 2 o 3 , 5%Al 2 o 3 ; The doping composition is P 2 o 5 、Eu 2 o 3 and Yb 2 o 3 , P 2 o 5 The dosage is 1% of the base composition, Eu2 o 3 The dosage is 0.5% of the base composition, Yb 2 o 3 The dosage is 2.5% of the base composition. According to the composition, analytically pure silicon dioxide, strontium carbonate, barium carbonate, boric acid, lanthanum oxide, aluminum oxide, ammonium dihydrogen phosphate, europium oxide, and ytterbium oxide were accurately weighed and mixed to obtain 30 g of batch materials. Thoroughly grind and mix the batch material in an agate mortar, then put it into a 50ml corundum crucible, place it in a high-temperature furnace at 1400°C and keep it warm for 1.5 hours to obtain a homogenized melt. The melt was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com