High temperature sensitized emulsion explosive and its preparation method

An emulsion explosive, high temperature technology, used in explosives processing equipment, explosives, non-explosive/non-thermal agent components, etc., can solve the problems of uneven density of latex matrix, fast decay of explosive performance, and untimely dispersion, and achieve accelerated production automation. Integrating with information technology, the performance of explosives decays slowly, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

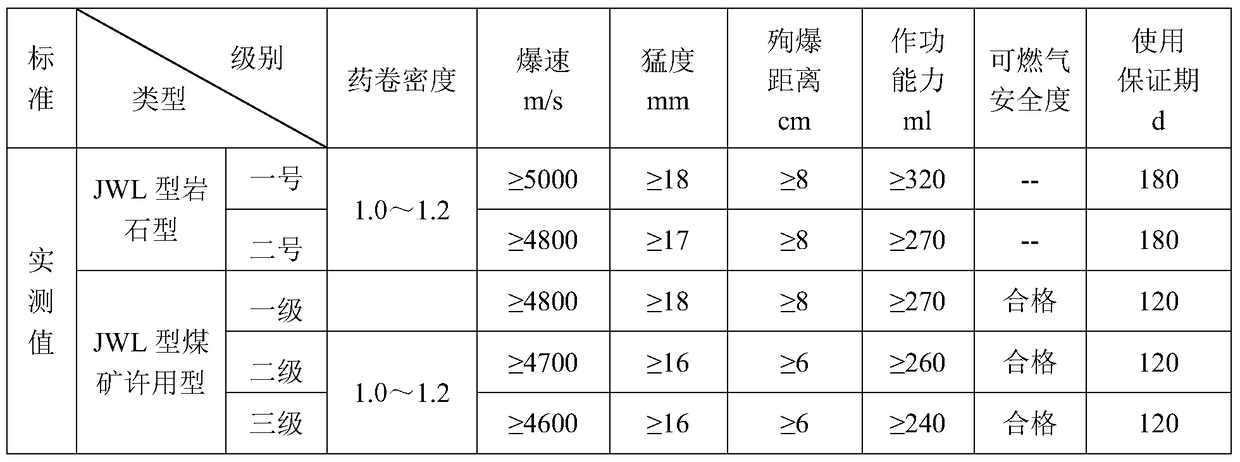

[0034] High temperature sensitized emulsion explosive, the explosive is prepared from the following raw materials in parts by weight: 75 parts of ammonium nitrate, 8 parts of sodium nitrate, 9 parts of water, integrated oil phase (paraffin: engine oil: vaseline: microcrystalline wax=20:30:45: 5) 5 parts, 1 part of sensitizer. The explosive with the above components is suitable for blasting No. 1 rock.

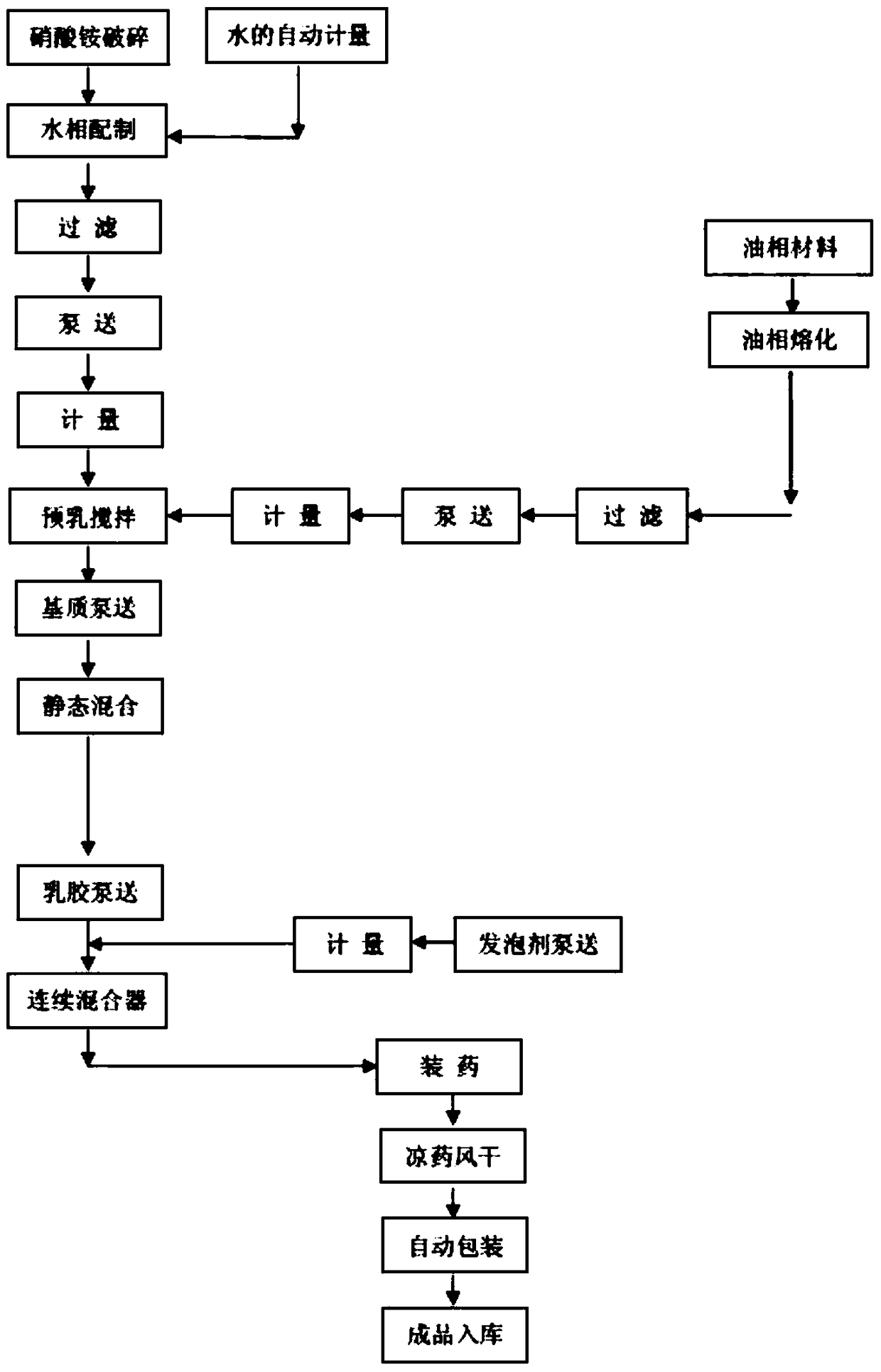

[0035] The preparation method is: (1) Water phase solution preparation: according to the formula ratio, when using liquid ammonium nitrate (mass concentration 91%, pH4), the liquid ammonium nitrate is pumped into the water phase preparation tank using a delivery pump, and water is added to dilute and stir , then adding sodium nitrate, heating to a temperature of 90°C-100°C while adding, keeping warm and stopping the reaction to obtain an aqueous phase solution;

[0036] (2) Preparation of oil phase solution: weigh the integrated oil phase and add it to the oil phase wax meltin...

Embodiment 2

[0040] High-temperature sensitized emulsion explosive, which is prepared from the following raw materials in parts by weight: 72 parts of ammonium nitrate, 10 parts of sodium nitrate, 10 parts of water, 6 parts of integrated oil phase, and 1.5 parts of sensitizer. The explosive with the above components is suitable for blasting No. 2 rock. The preparation method is the same as in Example 1.

Embodiment 3

[0042] High-temperature sensitized emulsion explosive, which is prepared from the following raw materials in parts by weight: 70 parts of ammonium nitrate, 10 parts of sodium nitrate, 2 parts of potassium chloride, 11 parts of water, 5.5 parts of integrated oil phase, and 2 parts of sensitizer. The explosives with the above components are suitable for blasting primary coal.

[0043] The preparation method is as follows: (1) When solid ammonium nitrate is used, firstly, the water is automatically quantitatively added to the water phase tank according to the formula ratio through the flow meter, and the steam is turned on (the steam pressure does not exceed 0.25MPa) to heat the water. When the temperature rises to 65°C When the crushed ammonium nitrate is sent to the water phase tank, when the temperature of the reaction solution is >75°C, start stirring and add sodium nitrate and potassium chloride, and continue heating to 95°C to stop heating and enter the automatic heat preser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com