Method for synthesizing nano three-way catalyst

A three-way catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of expensive oleylamine, difficult scale-up production, and loss of precious metals and other problems, to achieve the effect of being suitable for industrial scale-up production, adjustable and controllable in size, and easy to scale up production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

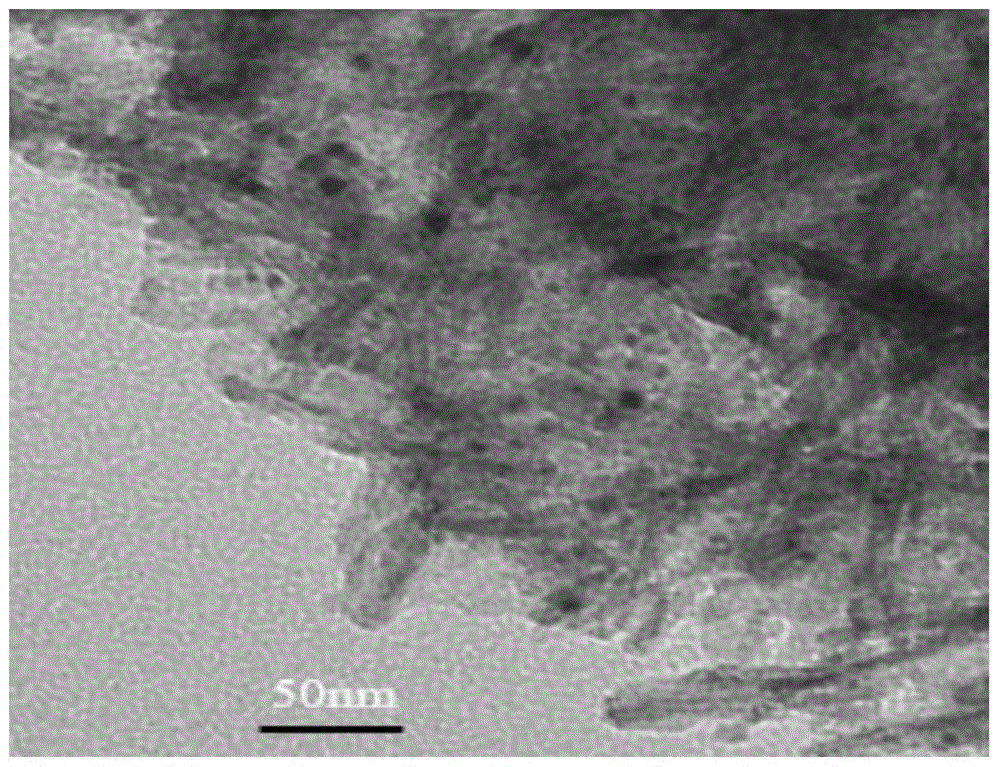

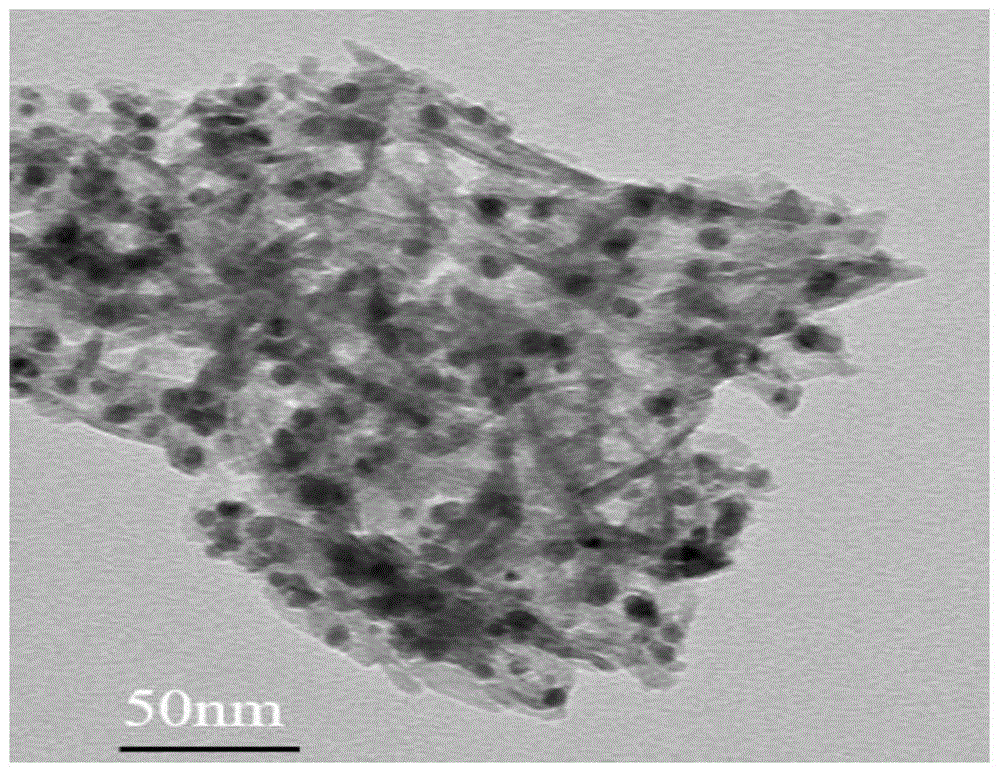

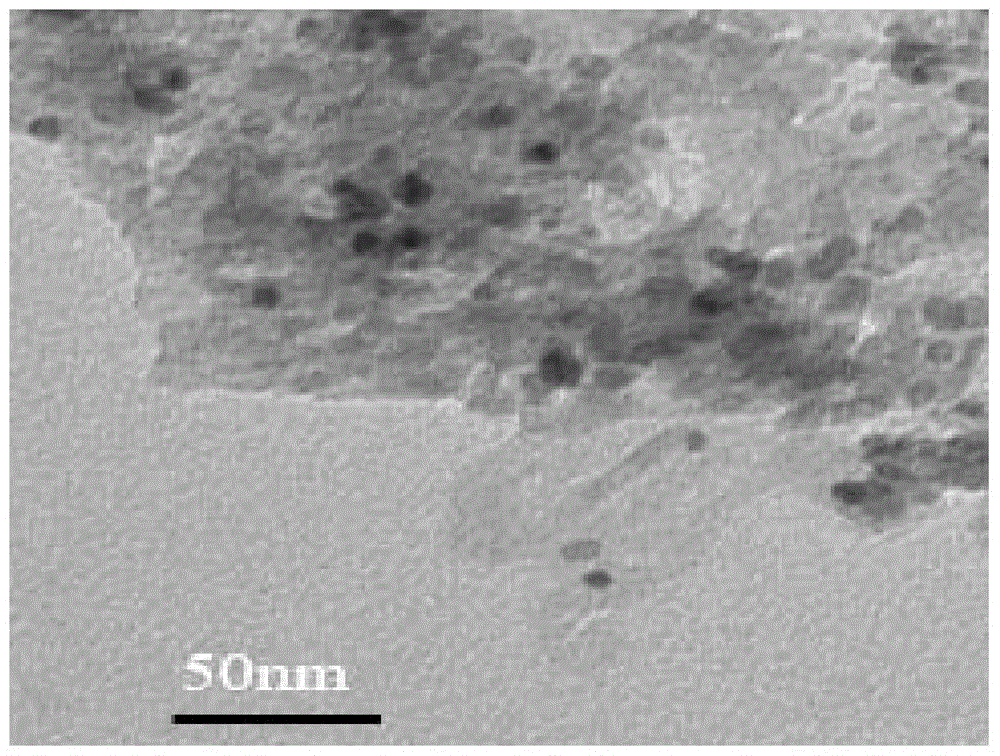

Image

Examples

Embodiment 1

[0036] Take 10ml of ethylene glycol, add 5g of alumina and 3g of sodium chloropalladate, heat to 160°C, keep the temperature for 6h, pour out the ethylene glycol solvent, wash the precipitate with ethanol, and dry it at 40°C to get all Pd nanoparticles effective catalyst powder.

Embodiment 2

[0038] Take 10ml of tert-butanol, add 0.1g of cobalt oxide and 0.3mg of sodium chloropalladate, heat to 300°C, keep the temperature for 12 hours, cool to room temperature, centrifuge, wash the resulting precipitate with ethanol, and dry it to obtain all Pd nanometer three effective catalyst powder.

Embodiment 3

[0040] Take 10ml of glycerol, add 0.1g of cerium-zirconium solid solution, 0.3g of palladium acetylacetonate and 50g of polyvinylpyrrolidone, heat to 60°C, add 100ml of 0.0001mol / L borane tert-butylamine in ethylene glycol, keep the temperature for 1min, pour After the alcohol solvent is removed, the obtained precipitate is washed with water and dried at 80° C. to obtain the all-Pd nanometer three-way catalyst powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com