Treatment method for removing fluorine and chlorine ions in acidic wastewater

A treatment method and chloride ion technology, applied in water/sewage treatment, degassed water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of low removal efficiency, incomplete separation, high heat consumption, etc. Achieve the effect of high separation efficiency, energy saving and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

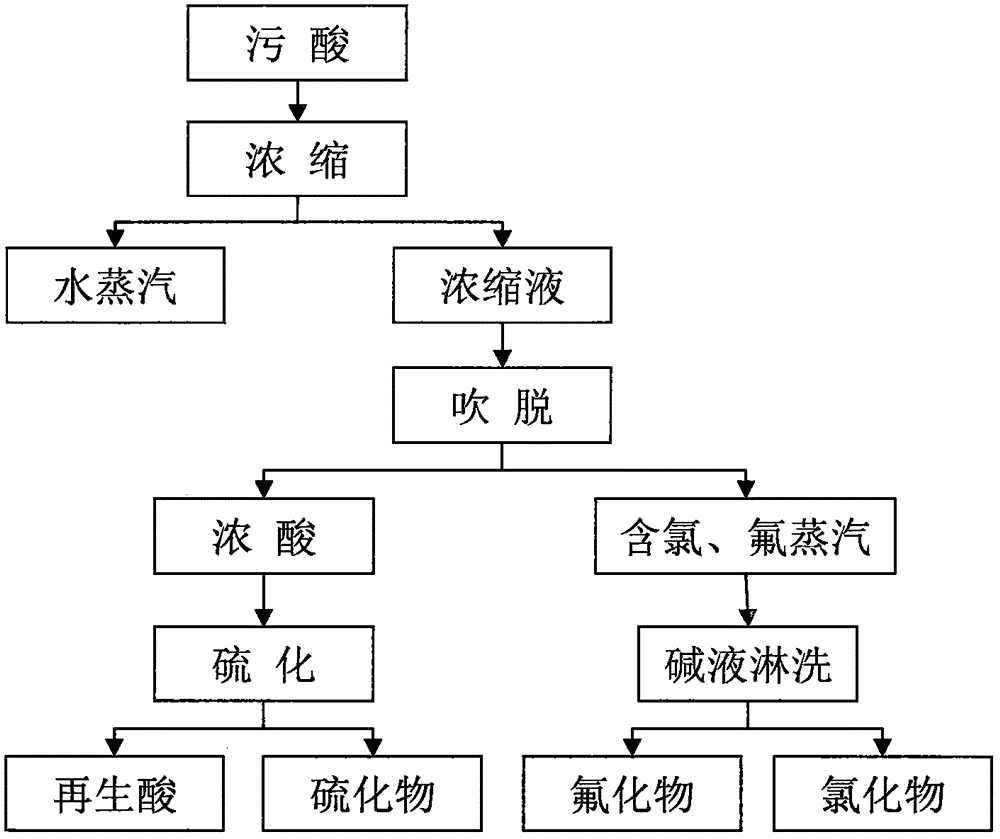

Image

Examples

Embodiment 1

[0023] Embodiment 1: the processing method of removing fluorine, chloride ion in polluted acid, comprises the following steps: after the polluted acid that contains fluorine 430mg / L, chlorine 530mg / L collects, concentrates in the concentrating tower, described polluted acid liquid from The top of the concentration tower is sprayed down to form small droplets. Hot air enters from the bottom of the concentration tower, and the countercurrent contact is performed for heat exchange. The dirty acid solution is quickly heated to 100°C, and a saturated vapor pressure zone of water is formed above the concentration tower. The obtained steam flows into the circulating pool after being condensed, and the dirty acid solution is concentrated in the concentration tower for multiple cycles until the mass percentage of sulfuric acid is 50%; It enters from the bottom of the tower and contacts in countercurrent for heat exchange. The volume ratio of gas to liquid is 10, and the concentrated liq...

Embodiment 2

[0024] Embodiment 2: the processing method of removing fluorine, chloride ion in polluted acid, comprises the following steps: after the polluted acid that contains fluorine 430mg / L, chlorine 530mg / L collects, concentrates in concentration tower, described polluted acid liquid from Spray down from the top of the concentration tower to form small droplets. Hot air enters from the bottom of the concentration tower and contacts in countercurrent for heat exchange. The dirty acid solution is quickly heated to 120°C, forming a saturated vapor pressure zone of water above the concentration tower. The obtained steam flows into the circulating pool after being condensed, and the dirty acid solution is concentrated in the concentration tower for multiple cycles until the mass percentage of sulfuric acid is 50%; It enters from the bottom of the tower, contacts in countercurrent for heat exchange, the volume ratio of gas to liquid is 50, and the concentrated liquid is heated to 200°C, the...

Embodiment 3

[0025]Embodiment 3: the processing method of removing fluorine, chloride ion in polluted acid, comprises the following steps: after the polluted acid that contains fluorine 430mg / L, chlorine 530mg / L collects, concentrates in the concentration tower, described polluted acid liquid from The top of the concentration tower is sprayed down to form small droplets. Hot air enters from the bottom of the concentration tower, and the countercurrent contact performs heat exchange. The dirty acid solution is quickly heated to 110°C, forming a saturated vapor pressure zone of water above the concentration tower, and Use a hydrophilic membrane to filter the steam, and the obtained steam flows into the circulating water pool after being condensed, and the dirty acid solution is concentrated in the concentration tower for multiple cycles until the mass percentage of sulfuric acid is 60%; the concentrated solution obtained by concentration is sprayed from the top of the stripping tower Next, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com