An insulated and cold-resistant flexible cable

A flexible cable and cold-resistant technology, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problem of material softness, increase the risk of plasticizer precipitation, increase the risk of plasticizer precipitation, etc. problems, to achieve high mechanical properties and anti-aging performance, reduce hardness, high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

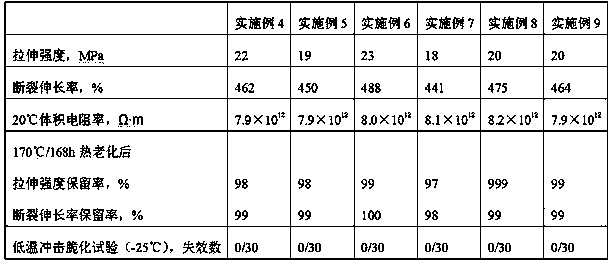

Examples

Embodiment 1

[0025] (1) Weigh 14.811g of phthalic anhydride and 10.514g of diethanolamine, first dissolve diisopropanolamine in 40mL of DMAc, dissolve it and pour it into a three-neck flask, then dissolve phthalic anhydride in 40ml of DMAc, and then It was slowly added dropwise into a three-necked flask, and reacted at room temperature for 3 hours under stirring to obtain AB 2 type monomer;

[0026] (2) Then add 60mL of toluene to the three-necked flask first, and then add 1.49g of trimethylolpropane as the nuclear molecule (nuclear molecule and AB 2 The molar ratio of the type monomer is 1:9), wait until the trimethylolpropane is completely dissolved, add 0.163g p-toluenesulfonic acid, heat to 130 degrees, condense and reflux for 24h, separate the generated water with a water separator, and finally Purified by vacuum distillation, this product is the second generation of hydroxyl-terminated hyperbranched polymer; (before the second step of reaction, first inject toluene into the water se...

Embodiment 2

[0030] (1) Weigh 22.217g of phthalic anhydride and 15.771g of diethanolamine, first dissolve diisopropanolamine in 40mL of DMAc, dissolve it and pour it into a three-neck flask, then dissolve phthalic anhydride in 40ml of DMAc, and then It was slowly added dropwise into a three-necked flask, and reacted at room temperature for 3 hours under stirring to obtain AB 2 type monomer;

[0031] (2) Then add 60mL of toluene to the three-necked flask first, and then add 0.958g of trimethylolpropane as the nuclear molecule (nuclear molecule and AB 2 The molar ratio of the type monomer is 1:21), wait until the trimethylolpropane is completely dissolved, add 0.245g p-toluenesulfonic acid, heat to 130 degrees, condense and reflux for 24h, separate the generated water with a water separator, and finally Purified by vacuum distillation, this product is the second generation of hydroxyl-terminated hyperbranched polymer; (before the second step of reaction, first inject toluene into the water ...

Embodiment 3

[0035] (1) Weigh 22.217g of phthalic anhydride and 15.771g of diethanolamine, first dissolve diisopropanolamine in 40mL of DMAc, dissolve it and pour it into a three-neck flask, then dissolve phthalic anhydride in 40ml of DMAc, and then It was slowly added dropwise into a three-necked flask, and reacted at room temperature for 3 hours under stirring to obtain AB 2 type monomer;

[0036] (2) Then add 60mL of toluene to the three-necked flask first, and then add 0.447g of trimethylolpropane as the nuclear molecule (nuclear molecule and AB 2 The molar ratio of the type monomer is 1:45), after the trimethylolpropane is completely dissolved, add 0.245g p-toluenesulfonic acid, heat to 130 degrees, condense and reflux for 24h, separate the generated water with a water separator, and finally Purified by vacuum distillation, this product is the second generation of hydroxyl-terminated hyperbranched polymer; (before the second step of reaction, first inject toluene into the water separ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com