Novel magnesian board

A new type of magnesium board technology, applied in the direction of covering/lining, layered products, chemical instruments and methods, etc., can solve the problems of fragile glass fiber mat surface, lack of toughness and strength, smoothness, etc., so as not to be easily broken, Convenient post-processing, good toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

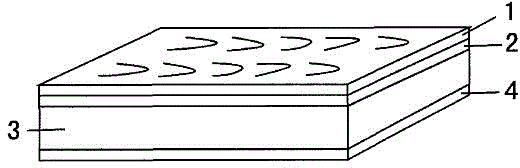

[0027] Such as figure 1 As shown, a new type of magnesium board is composed of four layers, namely: the first layer is the upper non-woven reinforcement layer 1, the main function is to make the surface smooth and convenient for later processing; the second and fourth layers are respectively The upper glass fiber mesh reinforcement layer 2 and the lower glass fiber mesh reinforcement layer 4 are mainly used to enhance the compressive strength and bending strength, and improve the flame retardant performance; the third layer is composed of organic compound adhesive and wood flour magnesium cementitious material Layer 3, which is located at the position of the middle layer, is used as the base layer. The cementitious material composed mainly of magnesium chloride, magnesium oxide, wood flour and polyvinyl alcohol is compounded. The weight ratio of the cementitious material in this embodiment is: wood flour 100-140kg, lithopone 20-30kg, perlite 25~30kg, magnesium chloride 250...

Embodiment 2

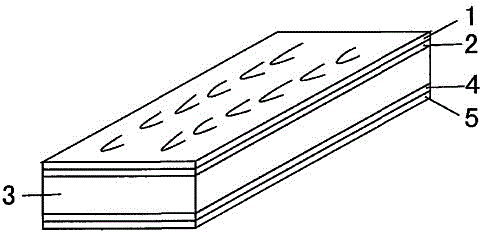

[0029] Such as figure 2 As shown, embodiment two is the same as the first to fourth layer structures of embodiment one, and the difference with embodiment one is that a fifth layer is added under the fourth layer of glass fiber mesh reinforcement layer 4, namely The lower non-woven reinforcing layer 5 .

Embodiment 3

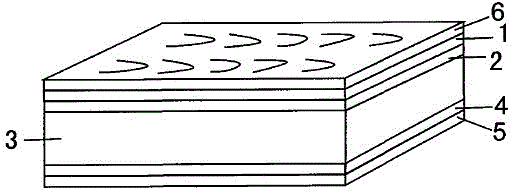

[0031] Such as image 3 As shown, this embodiment is the same as the first to fifth layer structures of the second embodiment, and the difference from the second embodiment is that a decorative layer 6 is provided on the surface of the non-woven reinforcement layer 1 on the first layer. In the example, the decorative layer 6 is made of natural wood veneer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com