Three-dimensional conductive network-supported porous silicon nanomaterial and preparation method and application thereof

A technology of nanomaterials and conductive networks, which is applied in the field of porous silicon nanomaterials and its preparation, can solve the problems of reduced specific capacity and energy density, no scalability, cumbersome synthesis process, etc., and achieves reduced production costs and good reliability. Scalability, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Mix porous silicon nanomaterials and graphene oxides converted from silica fume produced during the industrial smelting of metal silicon alloys in water at a mass ratio of 30:70, and prepare composite membranes by filtration. The obtained membranes After further drying for 12 h at 100 °C under hydrogen, a porous silicon nanomaterial supported by a three-dimensional graphene conductive network was prepared.

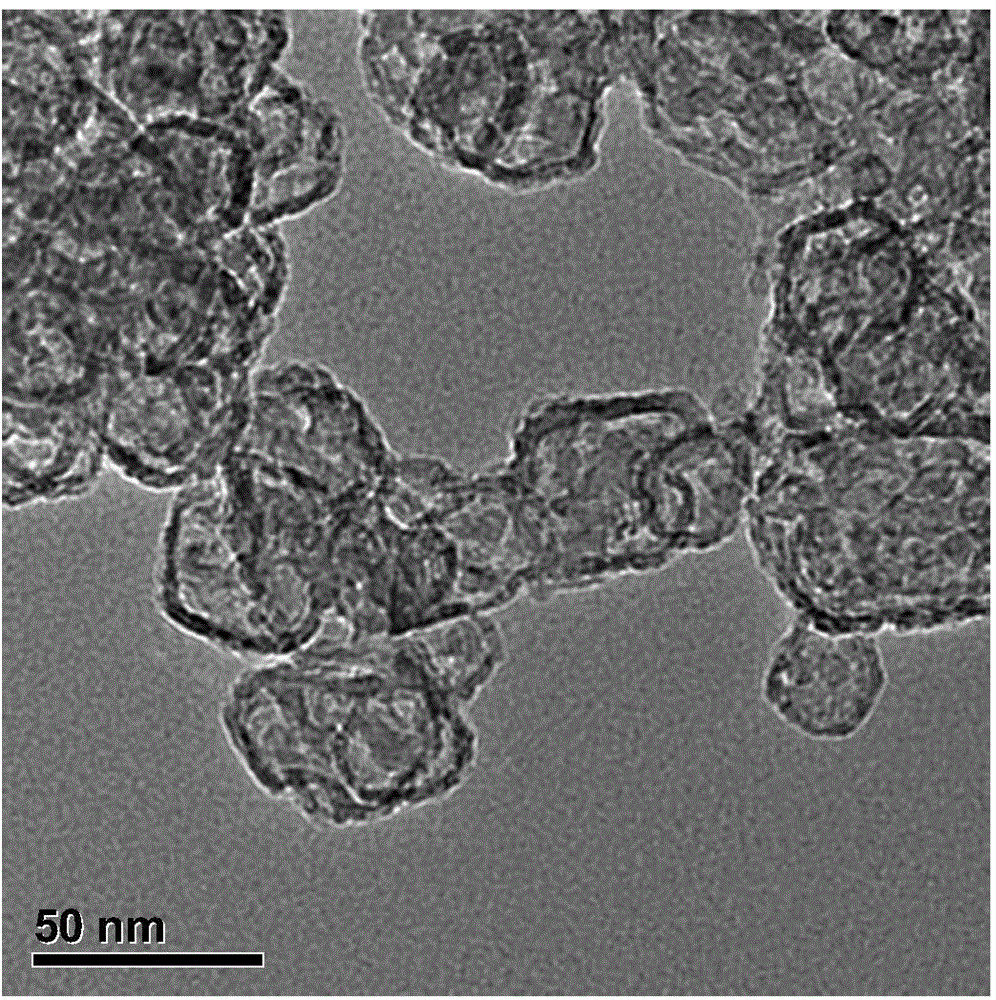

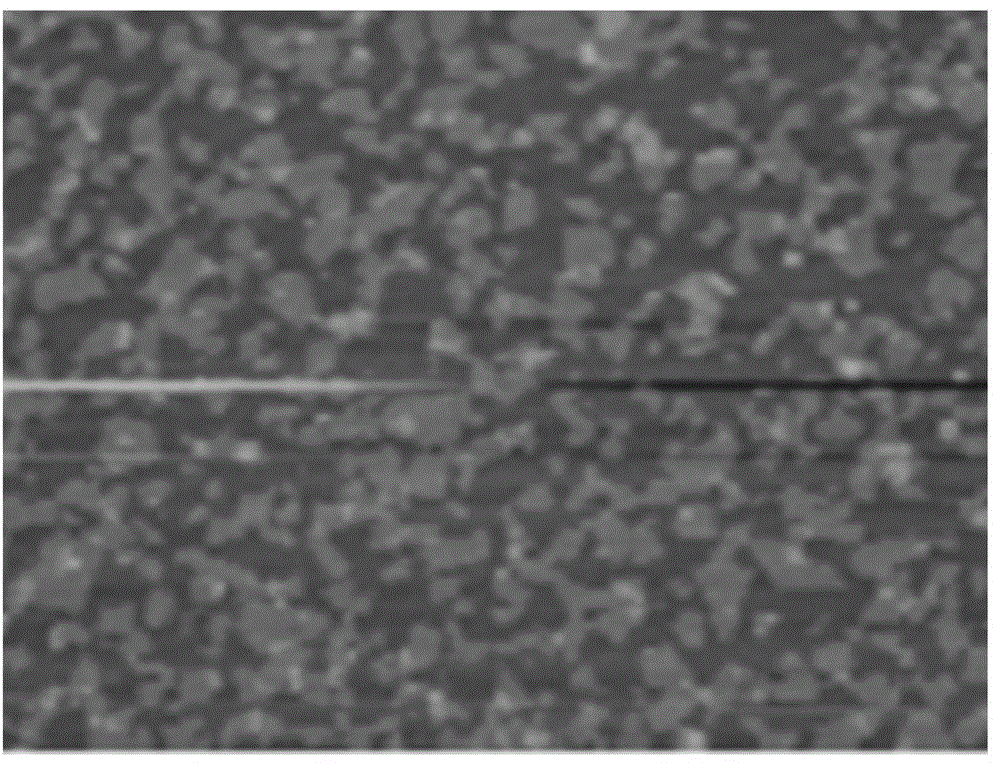

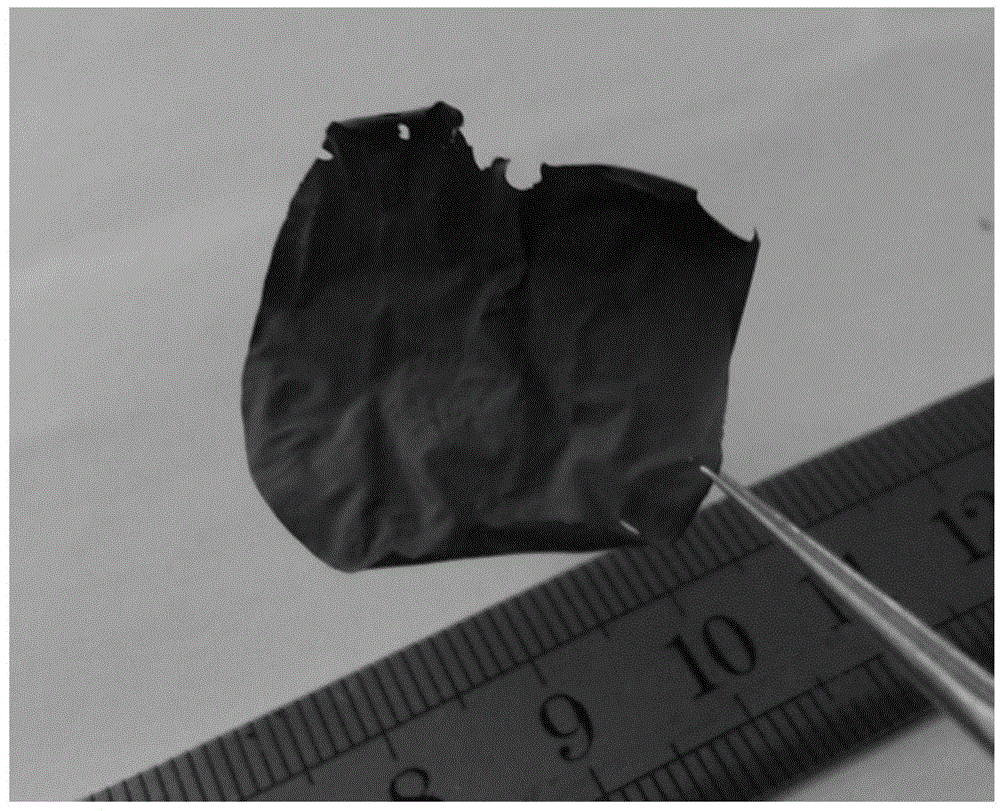

[0034] figure 2 For the AFM photo of the graphene oxide used in this embodiment; image 3 It is an optical photo of the porous silicon nanomaterial supported by three-dimensional graphene obtained in this example. from figure 2 , 3 It can be seen that the graphene oxide used in the present invention is a very thin two-dimensional sheet structure.

[0035] The porous silicon nanomaterial supported by the prepared three-dimensional graphene conductive network is directly used as the test electrode, and the metal lithium foil is used as the counter electrode. The...

Embodiment 2

[0037] Mix porous silicon nanomaterials and multi-walled carbon nanotubes in toluene at a mass ratio of 99:1, which are converted from silica fume produced during the industrial smelting of iron-silicon alloys, and prepare their composite films by spraying. Vacuum After drying, a porous silicon nanomaterial supported by a three-dimensional carbon nanotube conductive network is prepared.

[0038] Subsequent tests were as in Example 1. At a current density of 0.2C, the porous silicon nanomaterial supported by the three-dimensional carbon nanotube conductive network still has a specific capacity as high as 3100mAh / g; after 30 cycles, the capacity retention rate can reach 99%.

Embodiment 3

[0040]Mix porous silicon nanomaterials and bacterial cellulose in water at a mass ratio of 50:50, which are converted from silica fume produced during industrial smelting of metal silicon and iron-silicon alloys, and prepare composite films by drop coating , after the obtained film was heat-treated at 900°C for 0.5h in a mixed atmosphere of argon and hydrogen, a porous silicon nanomaterial supported by a three-dimensional carbon fiber conductive network was prepared.

[0041] Subsequent tests were as in Example 1. Under the current density of 0.2C, the porous silicon nanomaterial supported by the three-dimensional carbon fiber conductive network still has a specific capacity as high as 2550mAh / g; after 50 cycles, the capacity retention rate can reach 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com