Method of using coenzyme Q10 to prevent skin photoage

A skin photoaging and coenzyme technology, applied in skin care preparations, cosmetics, pharmaceutical formulations, etc., to improve skin permeability, reduce usage, and have good anti-photoaging effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of embodiment 1 coenzyme Q10 emulsion and nanoemulsion

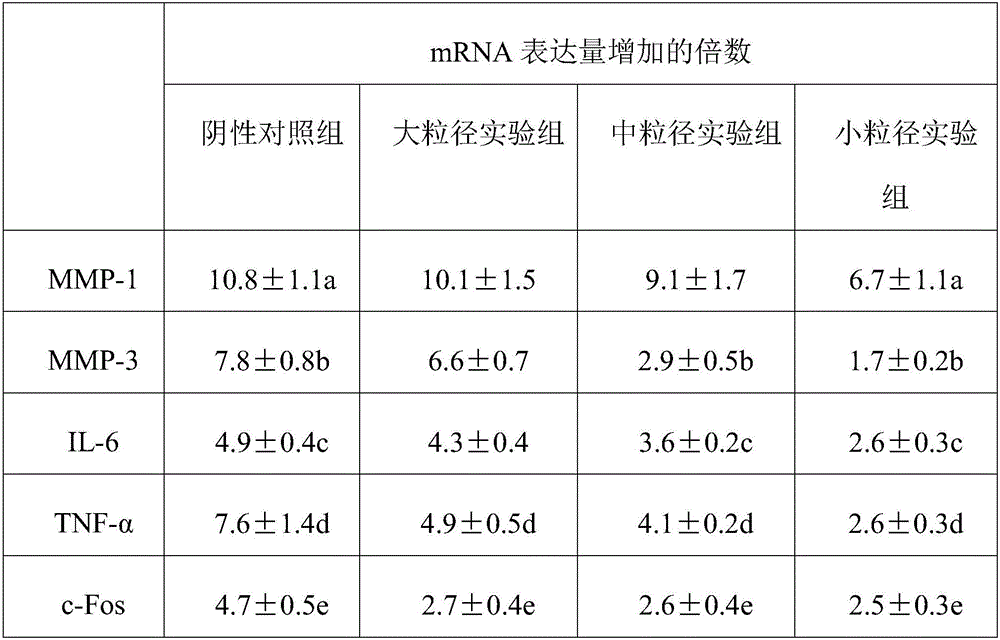

[0024] Weigh 2g of soybean lecithin, 81g of glycerin and 12g of deionized water and stir at 60°C to form a homogeneous mixture, then add 2.5g of coenzyme Q10 at 60°C to the mixture and stir, and then shear it with a high-shear homogenizer at 12000rmp A uniform coenzyme Q10 emulsion was formed in 3 minutes, and finally the emulsion was processed once through a high-pressure homogenizer cycle under the pressure of 250bar to obtain a large particle size coenzyme Q10 nanoemulsion (the particle size was measured to be about 344nm by a laser particle size analyzer), and then continue The coenzyme Q10 nano-emulsion with a large particle size continues to be recirculated once through a high-pressure homogenizer under a pressure condition of 750 bar to obtain a coenzyme Q10 nano-emulsion with a medium particle size (measured by a laser particle size analyzer at a particle size of about 185nm), and finally T...

Embodiment 2

[0025] The preparation of embodiment 2 coenzyme Q10 nanoemulsion

[0026] Weigh 0.1g of soybean lecithin, 90g of glycerin and 9.8g of deionized water and stir at 60°C to form a homogeneous mixture, then add 0.1g of coenzyme Q10 at 60°C to the mixture and stir, and a high-shear homogenizer at 12000rmp Cut for 3 minutes to form a uniform coenzyme Q10 emulsion, and finally pass the emulsion through a high-pressure homogenizer for 3 cycles under the pressure of 900 bar to obtain a small particle size coenzyme Q10 nanoemulsion (the particle size is about 52nm as measured by a laser particle size analyzer).

Embodiment 3

[0027] The preparation of embodiment 3 coenzyme Q10 nanoemulsion

[0028] Weigh 10g of soybean lecithin, 60g of glycerin and 20g of deionized water and stir at 70°C to form a homogeneous mixture, then add 10g of coenzyme Q10 at 70°C to the mixture, stir, and cut for 3min by a high-shear homogenizer at 12,000rmp A uniform coenzyme Q10 emulsion is formed, and finally the emulsion is processed through a high-pressure homogenizer cycle for 4 times under a pressure of 1000 bar to obtain a small particle size coenzyme Q10 nanoemulsion (the particle size is about 66 nm as measured by a laser particle size analyzer).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com