Erlotinib hydrochloride composition tablet and preparation method thereof

A technology of erlotinib hydrochloride and its composition, which is applied in the field of erlotinib hydrochloride composition tablet and its preparation, can solve problems affecting stability and the like, and achieve improved safety, high dissolution rate, and controllable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

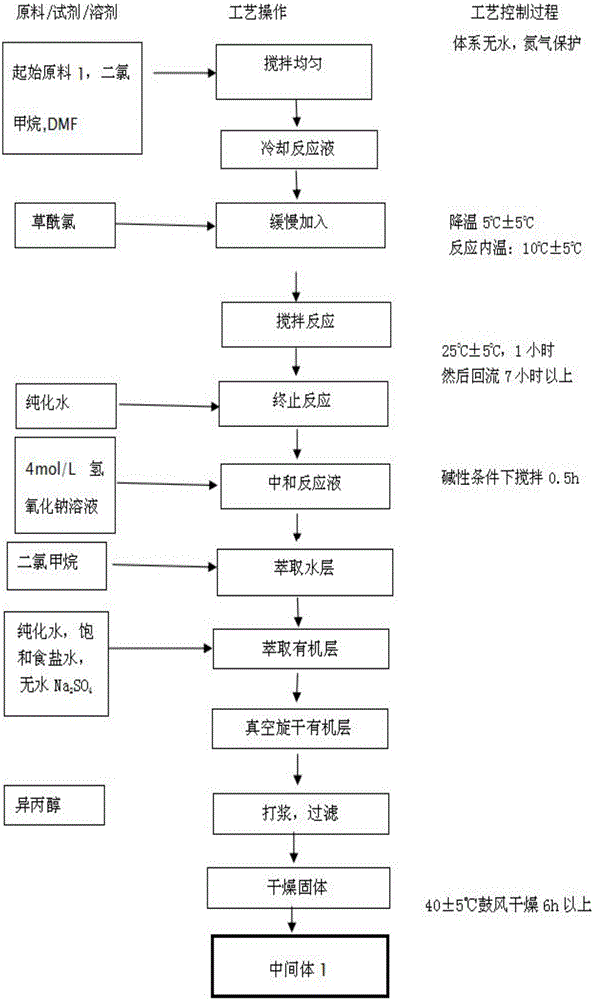

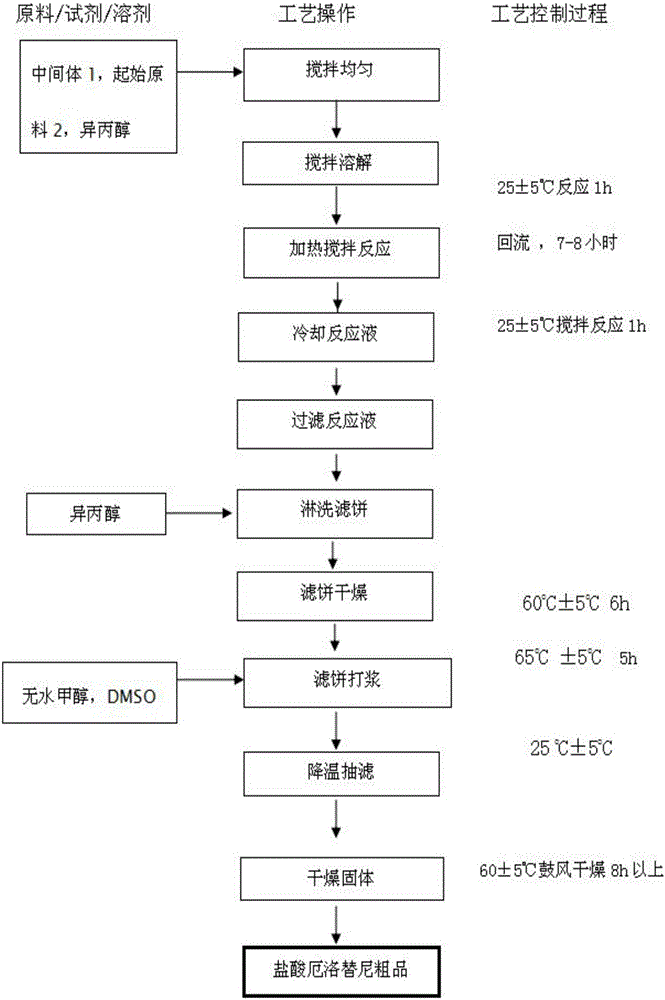

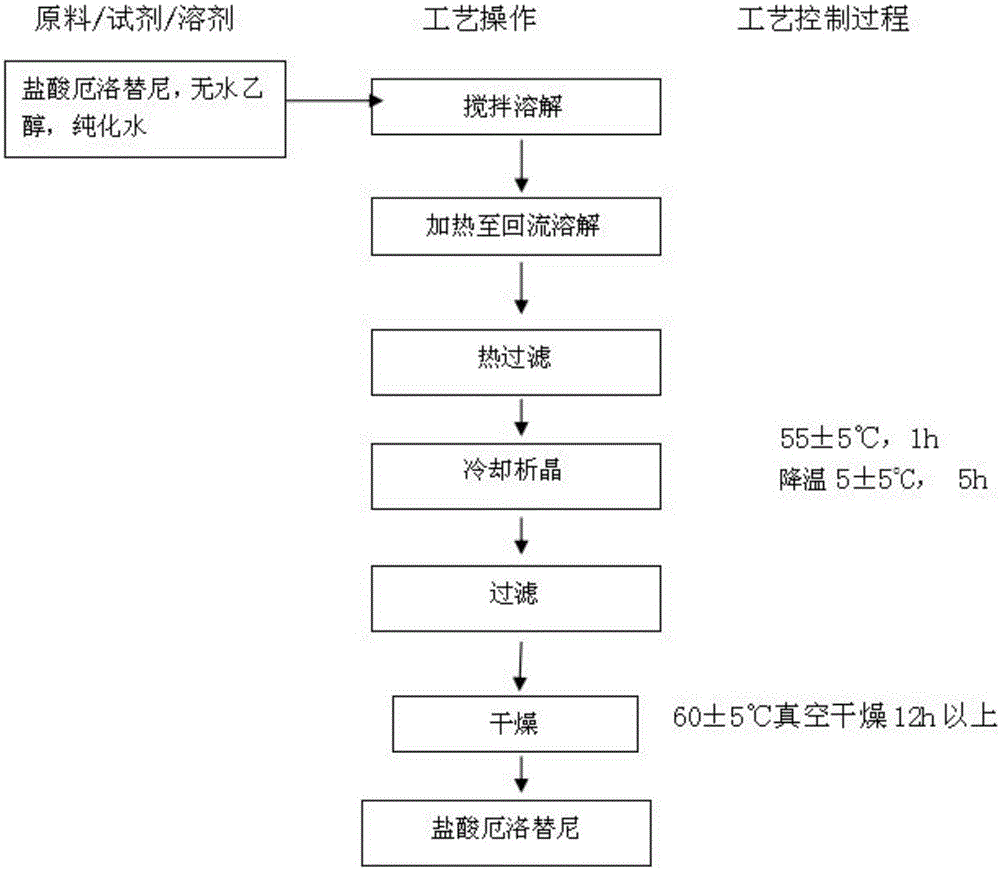

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of the above -mentioned Elotininini hydrochloride hydrochloric acid, including the following steps:

[0043] Step 1: Smoothylhutinin crystals with pre -intersecting starch, calcium sulfate, and sodium cross -linked carboxymethyl starch at 500R / min, mix well, crushed, over 100 destination sieve, obtain 100 destination mixture particlesIt

[0044] Step 2: Add the purified water and ethanol with a volume ratio of ethyl cellulose, β-cyclic paste, and vomiting temperature to 1: 2, stir well to get granular liquid, add the grain liquid to the mixture particles, and stir well.Filter and granulate, get wet particles, dry the dry particles at 80 ° C to get dry particles, control dry particles to free water ≤1.2 %;The weight ratio of a pure water and ethanol with a volume ratio of the base cellulose to the volume is 1: 2;

[0045] Step 3: Add sodium ricimate and microfiflo silicone to the 40 -purpose dry particles, stir well to get the mixture;

[0046] Step 4....

Embodiment 2

[0049] The preparation method of the above -mentioned Elotininini hydrochloride hydrochloric acid, including the following steps:

[0050] Step 1: Sodium Elotinib crystals hydrochloride and pre -intersecting starch, calcium sulfate, and sodium cross -linked carboxymethyl starch at 300r / min, mix well, crushed, and over 200 destination sieves, obtained 200 destination mixture particles granulesIt

[0051] Step 2: Add the purified water and ethanol with a volume ratio of ethyl cellulose, β-cyclic paste, and vomiting temperature to 1: 4, and stir well to get the grain liquid.Inside, the high -voltage power supply was applied to the high -voltage power supply on the stainless steel sprinkler, and the granular liquid was sprayed from the stainless steel sprinkler to the receiving device of the strong mixture particles.Dry the dry particles at 60 ° C, control dry particles to free water ≤1.2 %; the dry particles sieved over 60 destinations to obtain 60 destinations;The weight ratio of wa...

Embodiment 3

[0056] The preparation method of the above -mentioned Elotininini hydrochloride hydrochloric acid, including the following steps:

[0057] Step 1. Add the weight ratio to 1: 4, Elotinininibicin and polymethyl acrylic methyl ester to the second methyl sub -sarne solution, heat and stir until it is fully dissolved, obtain a mixture solution, input the mixture solution to the application to the applicationIn the stainless steel sprinkler with voltage, high -voltage static electricity is applied through a high -voltage power supply on the stainless steel sprinkler, and the mixture solution is sprayed from the stainless steel sprinkler to the volume ratio of 50 ° C in the volume ratio of 1: 1 methanol and water receiving device.After completion, stir for 2 hours, filter, the filter fluid at a frequency of 25kHz and the output power of 40W, cool at 5 ° C / hour to -5 ° C, raise crystal for 3 hours, wash, vacuum dry, get Hydrochloride Elotoen, get Hydrochloride Disari, get the hydrochloric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com