Preparation method of high-purity N-acetyl-D-glucosamine

A glucosamine, high-purity technology, applied in the field of preparation of high-purity N-acetyl-D-glucosamine, can solve the problem that it is difficult to ensure the yield and purity of the final product, the recrystallization conditions of multi-impurity crude products, and the high price of chitinase. problem, to achieve the effect of high product purity, simple preparation process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 20 g of chitin, add 80 mL of sulfuric acid with a mass concentration of 60%, and keep the temperature in a water bath at 60°C. After the degradation reaction at this temperature for 14 hours, unreacted chitin is removed by filtration. Sulfuric acid is removed by diffusion dialysis until the mass concentration of sulfuric acid is below 5%, and calcium hydroxide solid is added to adjust the pH of the solution to 5.5-7.0. Remove the precipitate by filtration, decolorize the filtrate with activated carbon, add absolute ethanol and stir, and collect the precipitate by filtration after the precipitation is complete. Slowly add purified water, while stirring, until the precipitate is just completely dissolved. Anhydrous ethanol was added again for recrystallization, and the precipitate was collected by filtration after the precipitation was complete. The obtained solid is dried under normal pressure to obtain the product N-acetyl-D-glucosamine, and the sample is assayed...

Embodiment 2

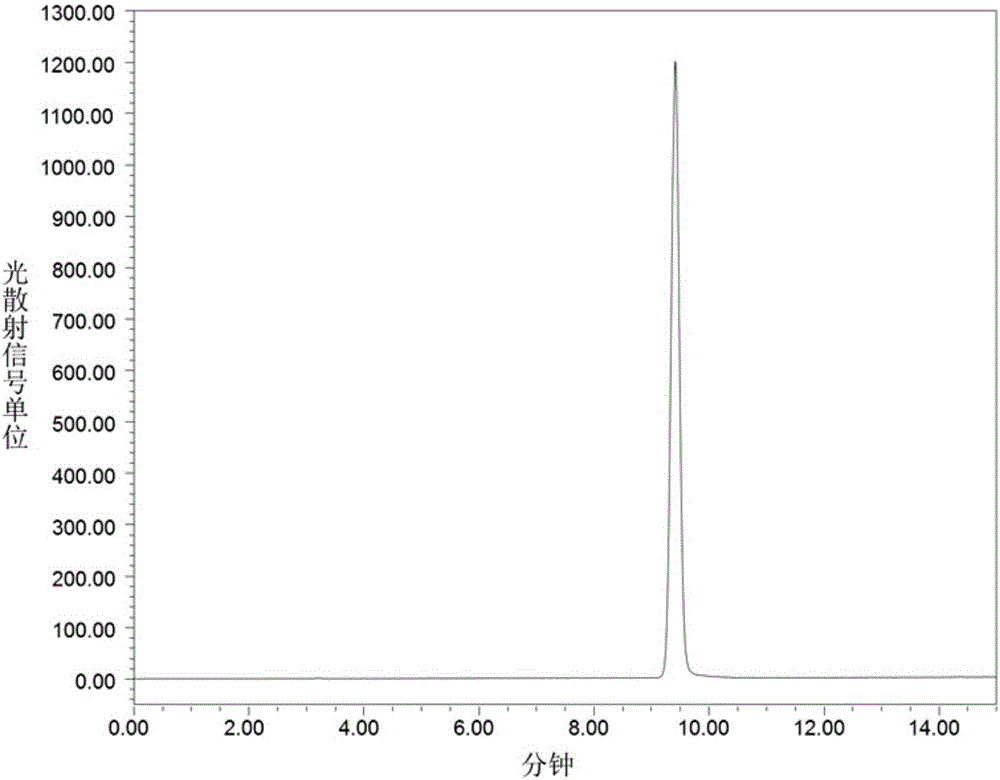

[0035] Weigh 20 g of chitin, add 40 mL of sulfuric acid with a mass concentration of 70%, and keep the temperature in a water bath at 40°C. After the degradation reaction at this temperature for 10 h, unreacted chitin is removed by filtration. Sulfuric acid is removed by diffusion dialysis until the mass concentration of sulfuric acid is below 5%, and calcium hydroxide solid is added to adjust the pH of the solution to 5.5-7.0. Remove the precipitate by filtration, at this time, the product in the filtrate is as figure 1 As shown, the filtrate was decolorized by activated carbon, then added absolute ethanol and stirred, and the precipitate was collected by filtration after the precipitation was complete. Slowly add purified water, while stirring, until the precipitate is just completely dissolved. Anhydrous ethanol was added again for recrystallization, and the precipitate was collected by filtration after the precipitation was complete. Gained solid obtains product N-acetyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com